Preparation method of tungsten alloy precursor compound powder, tungsten alloy and preparation method of tungsten alloy

A composite powder and tungsten alloy technology, which is applied in the field of high temperature structural materials, can solve the problems of the second phase aggregation and growth of tungsten alloy grains, uneven distribution of the second phase, and low hardness of tungsten alloy, so as to improve the internal elements. Distribute, solve low density, improve the effect of uniform consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

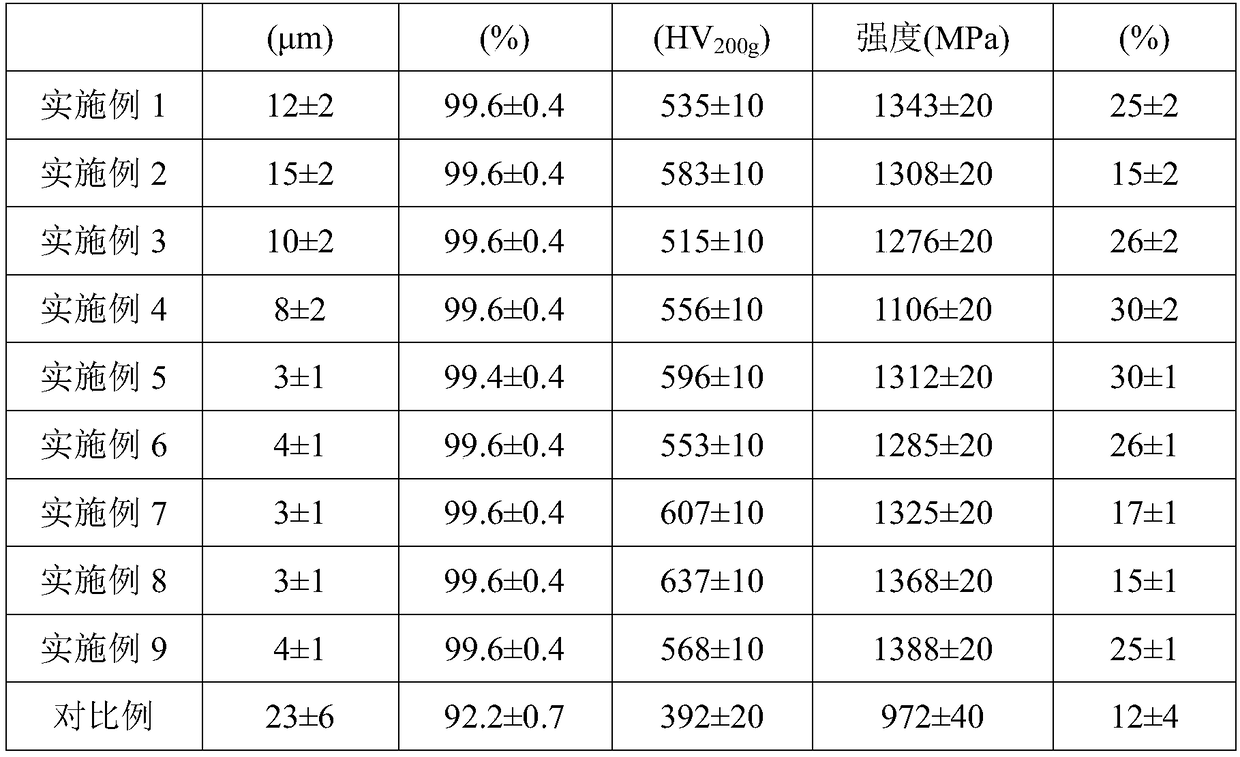

Examples

preparation example Construction

[0023] The invention provides a method for preparing a tungsten alloy precursor composite powder capable of improving the toughness of the tungsten alloy, comprising the following steps:

[0024] Provide a mixed dispersion of ammonium paratungstate, soluble iron salt, soluble nickel salt and soluble aluminum salt; use oxalic acid to adjust the pH of the mixed dispersion to not more than 1.5, complete the reaction, and then remove the solvent to obtain a mixed powder.

[0025] The preparation method of the tungsten alloy precursor composite powder of the present invention uses oxalic acid to adjust the pH of the mixed dispersion liquid, and the hydrogen ions and tungstate ions in the solution will react to form tungstic acid precipitation; oxalate ions and iron ions, nickel ions, aluminum The ions react to form iron oxalate, nickel oxalate and aluminum oxalate precipitates. Since the newly formed tungstic acid, iron oxalate, nickel oxalate and aluminum oxalate are the cause of c...

Embodiment 1

[0058] The preparation method of the tungsten alloy precursor composite powder of the present embodiment comprises the following steps:

[0059] 1) 131.28kg ammonium paratungstate (APT), 15.60kg nickel sulfate (NiSO 4 ·6H 2 O), 5.36kg iron sulfate [Fe 2 (SO 4 ) 3 ] and 0.84kg aluminum sulfate [Al 2 (SO 4 ) 3 ] was added to 51L of distilled water, and the mixed dispersion was obtained after the dissolution was complete;

[0060] Add oxalic acid to the resulting mixed dispersion to adjust the pH to 1.5, and then use a 100°C water bath to heat it. After the temperature of the mixed dispersion rises to 100°C, continue to use a 100°C water bath to heat the mixed dispersion. Stir; after the reaction is complete, suction filter and dry to obtain a mixed powder;

[0061] 2) Spread the obtained mixed powder into a material layer with a thickness of 5 mm and then calcinate at 550 ° C for 1 h, then put the calcined product into a tubular reduction furnace, spread it into a materi...

Embodiment 2

[0063] The preparation method of the tungsten alloy precursor composite powder of the present embodiment comprises the following steps:

[0064] 1) 134.26kg ammonium paratungstate (APT), 9.36kg nickel sulfate (NiSO 4 ·6H 2 O), 3.21kg iron sulfate [Fe 2 (SO 4 ) 3 ] and 0.34kg aluminum sulfate [Al 2 (SO 4 ) 3 ] was added to 49L of distilled water, and the mixed dispersion was obtained after the dissolution was complete;

[0065] Add oxalic acid to the resulting mixed dispersion to adjust the pH to 1.5, and then use a 90°C water bath to heat it. After the temperature of the mixed dispersion rises to 90°C, continue to use a 90°C water bath to heat the mixed dispersion. Stir; after the reaction is complete, suction filter and dry to obtain a mixed powder;

[0066] 2) Spread the obtained mixed powder into a material layer with a thickness of 6mm, and then calcinate it at 550°C for 1.5h, then put the calcined product into a tubular reduction furnace, spread it into a material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com