Method and apparatus for sorbent production, primarily for removing arsenic from drinking water

An adsorbent, drinking water technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

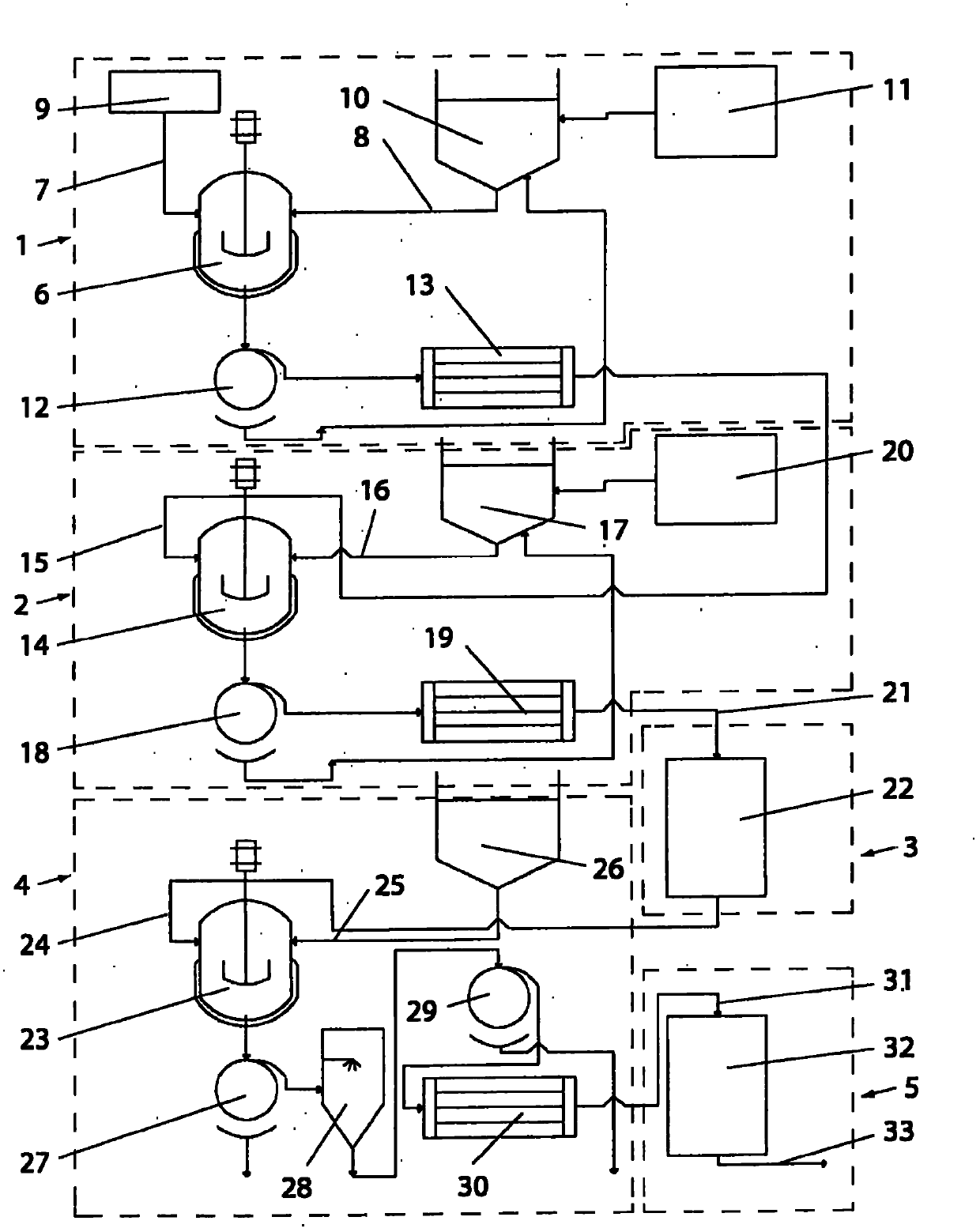

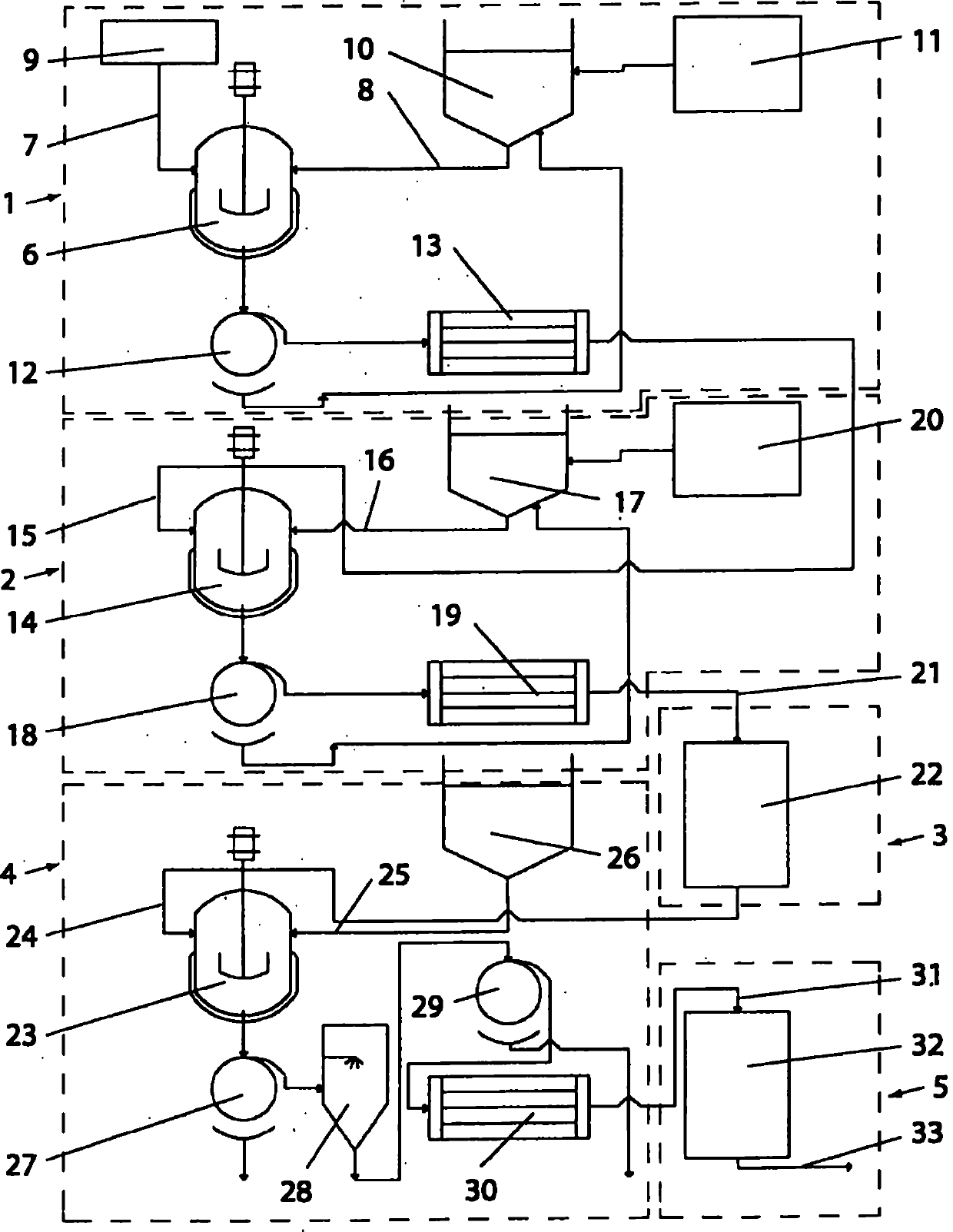

[0036] In the first saturation unit 1 , a carrier material container 9 is connected to the first autoclave 6 via a first carrier material inlet 7 . Like all other parts of the plant, the first autoclave 6 is a commercially available conventional device. The first autoclave 6 is also connected to a first solution tank 10 through a first solution inlet 8 . A ferric salt container 11 suitable for storing water-soluble ferrous salt is connected to the first solution tank 10 . Saturated carrier material is fed from the first autoclave 6 to the first filter 12 and from the first filter 12 to the first dryer 13 . The filtered ferrous salt solution is recycled from the first filter 12 to the first solution tank 10 .

[0037] In the second saturation unit 2 , the support material saturated with the iron salt solution is fed to the second autoclave 14 through the second support material inlet 15 . The second carrier material inlet 15 is connected to the first dryer 13 . The second a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com