Ternary silicate composite cathode material and preparation method therefor

A composite positive electrode material and positive electrode material technology, applied in the field of ternary silicate composite positive electrode material and its preparation, can solve the problems of lithium volatilization loss, intensified non-stoichiometric degree and cation mixing, and achieve less emission, electrochemical The effect of excellent performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

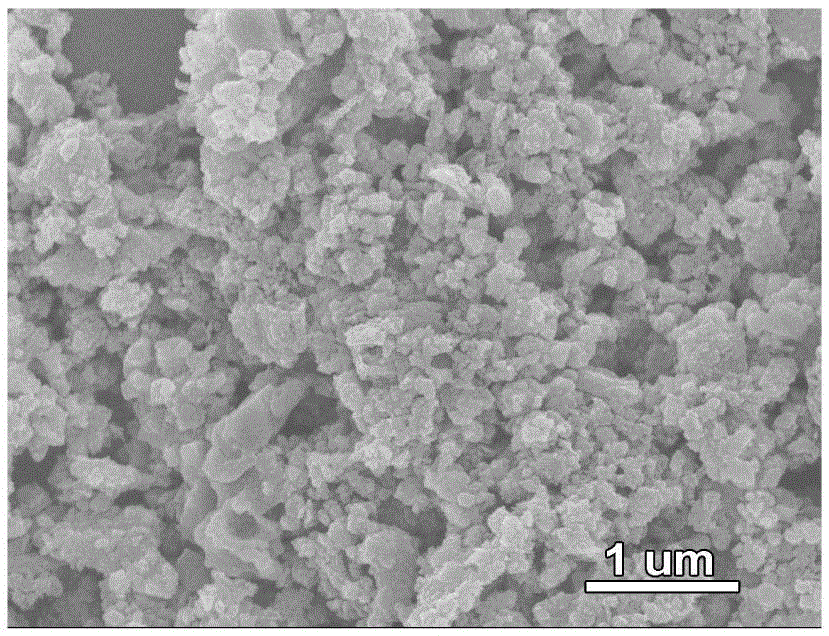

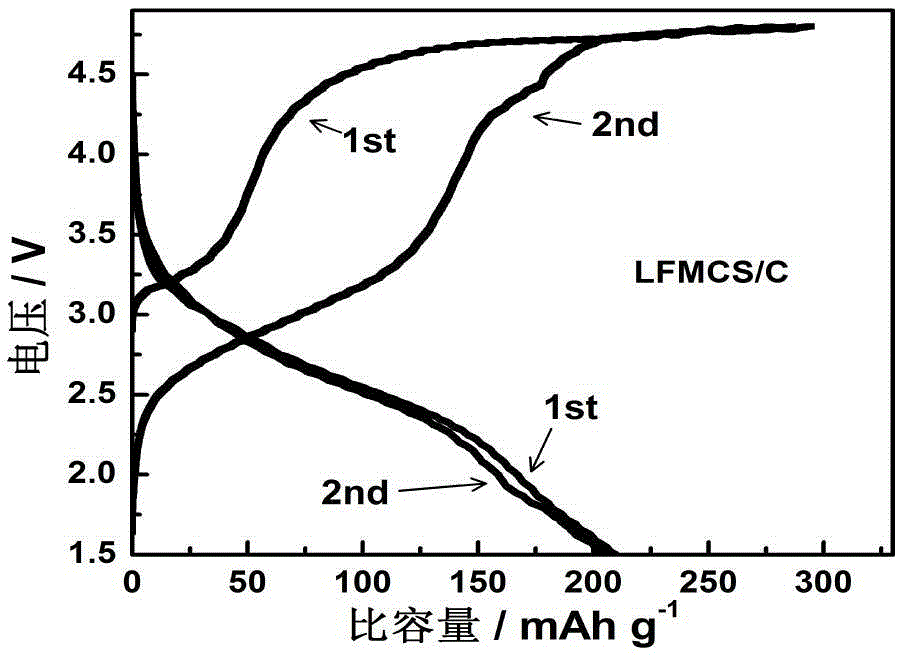

[0036] The drug and molar ratio required to prepare the sample satisfy the following relationship: LiCH 3 COO·2H 2 O:FeC 2 o 4 2H 2 O:Mn(CH 3 COO) 2 4H 2 O:Ni(CH 3 COO) 2 4H 2 O:(C 2 h 5 ) 4 SiO 4 = 2.04:1 / 3:1 / 3:1 / 3:1. FeC 2 o 4 2H 2 O, Mn(CH 3 COO) 2 4H 2 O and Ni(CH 3 COO) 2 4H 2 O is placed in a container with a molar ratio of 1:1:1, and stirred for 30 min with absolute ethanol as a medium to obtain a mixed solution 1; LiCH 3 COO·2H 2 O was added to the mixed solution 1, stirred for 30min; then added (C 2 h 5 ) 4 SiO 4 Continue to stir for 30 minutes to obtain the mixed solution 2; keep the mixed solution 2 at a constant temperature of 80°C for 24 hours, bake it under an infrared lamp, and stir until the solvent is completely evaporated to obtain a dry material; dry the material in a vacuum oven at 100°C for 12 hours , cooled to room temperature; adding sucrose with a mass fraction of 15% to the above-mentioned dried material, using acetone as th...

Embodiment 2

[0038] The drugs and molar ratios required to prepare samples satisfy the following relationship: LiCH 3 COO·2H 2 O:FeC 2 o 4 2H 2 O:Mn(CH 3 COO) 2 4H 2 O:Ni(CH 3 COO) 2 4H 2 O:(C 2 h 5 ) 4 SiO 4 = 2.04:1 / 3:1 / 3:1 / 3:1. FeC 2 o 4 2H 2 O, Mn(CH 3 COO) 2 4H 2 O and Ni(CH 3 COO) 2 4H 2 O is placed in a container with a molar ratio of 1:1:1, and stirred for 30 min with absolute ethanol as a medium to obtain a mixed solution 1; LiCH 3 COO·2H 2 O was added to the mixed solution 1, stirred for 30min; then added (C 2 h 5 ) 4 SiO 4 Continue to stir for 30 minutes to obtain the mixed solution 2; keep the mixed solution 2 at a constant temperature of 80°C for 24 hours, bake it under an infrared lamp, and stir until the solvent is completely evaporated to obtain a dry material; dry the material in a vacuum oven at 100°C for 12 hours , cooled to room temperature; adding mass fraction to the dried material is 10% ascorbic acid, using acetone as medium, ball milling...

Embodiment 3

[0040] The drug and molar ratio required to prepare the sample satisfy the following relationship: LiCH 3 COO·2H 2 O:FeC 2 o 4 2H 2 O:Mn(CH 3 COO) 2 4H 2 O:Co(CH 3 COO) 2 4H 2 O:(C 2 h 5 ) 4 SiO 4 = 2.04:1 / 3:1 / 3:1 / 3:1. FeC 2 o 4 2H 2 O, Mn(CH 3 COO) 2 4H 2 O and Co(CH3 COO) 2 4H 2 O is placed in a container with a molar ratio of 1:1:1, and stirred for 30 min with absolute ethanol as a medium to obtain a mixed solution 1; LiCH 3 COO·2H 2 O was added to the mixed solution 1, stirred for 30min; then added (C 2 h 5 ) 4 SiO 4 Continue to stir for 30 minutes to obtain the mixed solution 2; keep the mixed solution 2 at a constant temperature of 80°C for 24 hours, bake it under an infrared lamp, and stir until the solvent is completely evaporated to obtain a dry material; dry the material in a vacuum oven at 100°C for 12 hours , cooled to room temperature; adding mass fraction of 12.3% sucrose to the dried material, using acetone as medium, ball milled for 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com