A preparing method of a catalyst used for preparing low-carbon olefins from synthetic gas and applications of the catalyst

A low-carbon olefin and catalyst technology, which is applied in the field of catalyst preparation, can solve the problems of wide catalyst particle size distribution, reduced synthesis gas utilization rate, low product added value, etc., and achieves good reaction product distribution, improved utilization rate, and short cycle time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

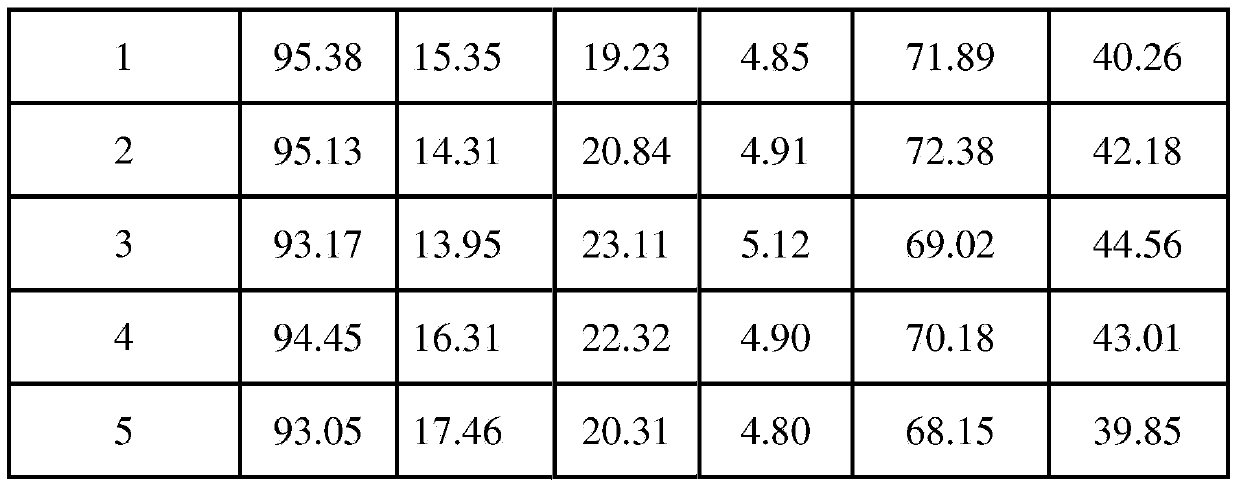

Embodiment 1

[0025] Weigh Fe(NO 3 ) 3 9H 2 O40.25g, ZrO(NO 3 ) 2 2H 2 O4.44g, Zn(NO 3 ) 2 ·6H 2 03.66g is mixed with homogeneous mixed solution 100mL, is precipitating agent with urea, takes by weighing urea 21.42g, adds in the prepared homogeneous mixed solution and stirs; The mixed solution that stirs is transferred in the dissolving cup of TFM material, in Microwave 2450MHz, pressure 1.5MPa, power 300W, heat for 180min, drop to room temperature, suction filter, wash the obtained precipitate until neutral, dry at 50℃ overnight, roast in a muffle furnace at 350℃ for 6h to obtain powder A; weigh 5g Powder A, 0.15g K 2 CO 3 , Measure 5g of powder A saturated water absorption volume of distilled water will be weighed K 2 CO 3 Prepare a solution, impregnate 5 g of powder with equal volume, and dry in an oven at 60°C after impregnation to obtain powder B. Grind B, tablet and granulate it to 20-40 mesh to obtain a catalyst.

[0026] The application process of the catalyst used to pr...

Embodiment 2

[0029] Weigh Fe 2 (C 2 o 4 ) 3 ·5H 2 O16.47g, Zr(NO 3 ) 4 ·5H 2 O15.18g, Zn(NO 3 ) 2 ·6H 2 07.32g is mixed with homogeneous mixed solution 100mL, is precipitating agent with urea, takes by weighing urea 19.94g, adds in the prepared homogeneous mixed solution and stirs; The mixed solution that stirs is transferred in the dissolving cup of TFM material, in Microwave 2450MHz, pressure 2MPa, power 400W, heat for 150min, drop to room temperature, suction filter, wash the obtained precipitate until neutral, dry overnight at 80℃, then roast in a muffle furnace at 550℃ for 3h to obtain powder A; weigh 5g of powder A, 0.22g K 2 CO 3 , Measure 5g of powder A saturated water absorption volume of distilled water will be weighed K 2 CO 3 Prepare a solution, impregnate 5 g of powder with equal volume, and dry in an oven at 90°C after impregnation to obtain powder B. Grind, tablet and granulate B to 20-40 mesh to obtain a catalyst.

[0030] The application process of the cataly...

Embodiment 3

[0033] Weigh Fe 2 (C 2 o 4 ) 3 ·5H 2 O8.80g, ZrOCl 2 ·8H 2 O18.26g, Zn(NO 3 ) 2 ·6H 2 03.66g is mixed with homogeneous mixed solution 100mL, is precipitating agent with urea, takes by weighing urea 15.09g, adds in the prepared homogeneous mixed solution and stirs; The mixed solution that stirs is transferred in the dissolving cup of TFM material, in Microwave 2450MHz, pressure 2.5MPa, power 500W, heat for 60min, drop to room temperature, suction filter, wash the obtained precipitate until neutral, dry overnight at 120°C, roast in a muffle furnace at 450°C for 5h to obtain powder A; weigh 5g Powder A, 0.3g K 2 CO 3 , Measure 5g of powder A saturated water absorption volume of distilled water will be weighed K 2 CO 3 Prepare a solution, impregnate 5 g of powder with equal volume, and dry in an oven at 120°C after impregnation to obtain powder B. Grind, tablet and granulate B to 20-40 mesh to obtain a catalyst.

[0034] The application process of the catalyst used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com