Method for preparing photoelectrode of alpha-iron oxide film by single-source precursor

A technology of iron oxide and photoelectrode, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of precursor regulation and control, achieve the effects of controllable thickness, simplify the preparation process, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

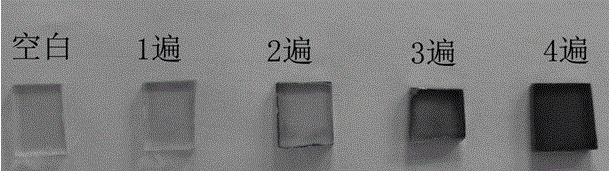

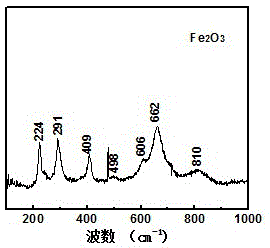

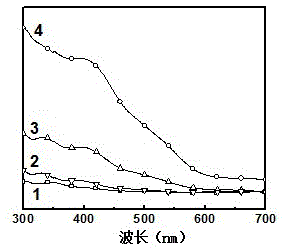

[0047] Example 1: Ferric ammonium citrate prepares undoped ferric oxide

[0048] The FTO conductive substrate is ultrasonically washed with ethanol, distilled water, hydrogen peroxide-ammonia-water, and distilled water for 5-10 minutes respectively, and then dried naturally in the air for later use; ferric ammonium citrate (NH4) 3FeC12H10O14 salt is dissolved in distilled water to prepare The aqueous solution with a concentration of 0.0025mol / L is then poured into the lining of the reactor with a filling degree of 10-70%; put the cleaned substrate into the lining vertically or horizontally with the conductive side facing up, and seal the autoclave; React in an oven at 180°C for 16 hours; take out the substrate on which the film is deposited, wash it with distilled water, and dry it naturally to obtain an α-Fe2O3 film; repeat this step to obtain an α-Fe2O3 film with adjustable thickness.

example 2

[0049] Example 2: Ferric ammonium citrate prepares Sn-doped ferric oxide

[0050] The conductive substrate is treated as in Example 1; dissolving ferric ammonium citrate in distilled water to form an aqueous solution with a concentration of 0.0025mol / L, adding 1mol / L HCl to adjust the pH=1~3, and then adding SnCl2 2H2O solution (keep [ Sn] / [Fe]=3-5%), transfer to the lining of the reaction kettle, the filling degree is 10-70%; put the cleaned substrate into the lining vertically or horizontally with the conductive side up, and seal it Autoclave; react in an oven at 180°C for 16 hours; take out the substrate on which the film is deposited, wash with distilled water, and dry naturally to obtain a Sn-doped α-Fe2O3 film; repeat this step to obtain a doped α-Fe2O3 film with adjustable thickness -Fe2O3 film.

example 3

[0051] Example 3: Ferric ammonium oxalate prepares undoped ferric oxide

[0052] The conductive substrate is treated as example 1; high ammonium oxalate (NH ) 3 Fe (C ) 4) 3 salt is dissolved in distilled water and is made into the aqueous solution that concentration is 0.0005mol / L, then pours in the reactor liner, filling degree is 10 -70%; put the cleaned substrate into the liner vertically or horizontally with the conductive side up, and seal the autoclave; react in an oven at 100°C for 12 hours; take out the substrate with the film deposited, wash it with distilled water, Dry naturally to obtain α-Fe2O3 film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com