Efficient and energy-saving waste plastic recycling and granulating complete device

A waste plastic, high-efficiency and energy-saving technology, applied in coatings and other directions, can solve the problems of low output, high energy consumption, low degree of automation, etc., and achieve the effect of low energy consumption ratio, prolonging the screen change time, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

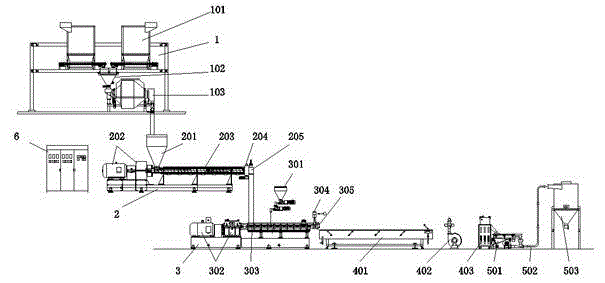

[0019] The high-efficiency and energy-saving waste plastic recycling and granulation complete set of equipment of the present invention includes a main control device 6, a raw material supply device 1, an extrusion unit device, a granulation auxiliary device 4 and a finished product conveying device 5 connected in sequence. The main control device 6 controls the operation of all devices, implements the collection of various data, and provides a man-machine interface, uses various information for real-time processing, and realizes automatic management.

[0020] The raw material supply device 1 includes a screw conveying device 101 , an automatic quantitative weighing device 102 and a mixing barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com