Toughening furnace for continuously producing half strengthened glass and production method of toughening furnace

A production method and tempering furnace technology, which is applied in the field of tempering furnaces and continuous production of semi-tempered glass, can solve the problems of weak wind blowing strength, long waiting time, and limited length of cooling section, and achieve the effect of improving work efficiency and excellent flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

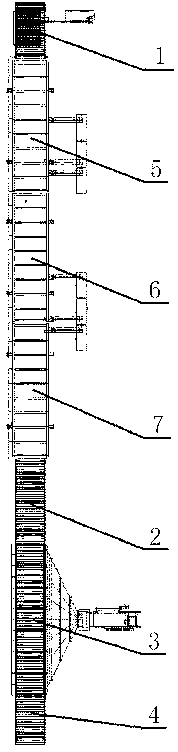

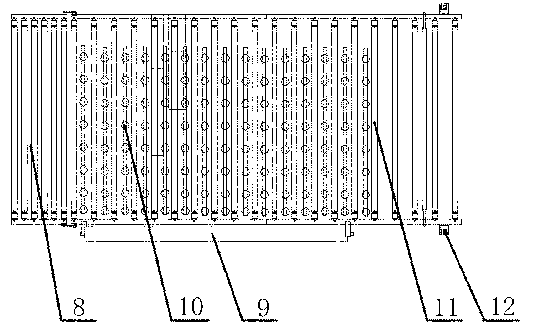

[0022] Such as figure 1 , figure 2 As shown, the upper area 1, the heating area, the self-cooling area 2, the air cooling area 3 and the lower area 4 are arranged in sequence, and the heating area includes the first heating section 5, the second heating section 6 and the third heating section 7, and the first heating section Section 5, the second heating section 6 and the third heating section 7 adopt different heating temperatures, and their lengths are all 10 meters. Both the upper film area 1 and the lower film area 4 have the function of two-way unloading, and the upper film area 1 includes a horizontal film loading roller 8. Vertical film loading roller 9, universal wheel 10, transmission roller 11 and positioning cat's eye 12, horizontal film loading roller 8 and the left side of transmission roller 11, vertical film loading roller 9 and transmission roller The lower side of 11 is attached, the universal wheel 10 is arranged between the rollers in the intersection area...

Embodiment 2

[0024] The 6mm thick glass is transported to the heating zone by the roller passing through the upper area. The heating time of the first heating section is 90s, and the heating temperature is 690°C. The heating time of the second heating section is 90s, and the heating temperature is 695°C. The heating time of the third heating section is 90s, and the heating temperature is 685°C; then the glass is transported to the self-cooling zone, the cooling time is 50s, and the temperature drops to 300°C; then it is transported to the air-cooling zone, the wind pressure is 2000Pa, and the cooling time is 45s , the height of the air grille is 25mm, and the temperature drops to 65°C.

Embodiment 3

[0026] The 8mm thick glass is transported to the heating zone by the roller passing through the upper area. The heating time of the first heating section is 135s, and the heating temperature is 687°C. The heating time of the second heating section is 130s, and the heating temperature is 698°C. The heating time of the three heating sections is 138s, and the heating temperature is 686°C; then the glass is transported to the self-cooling zone, the cooling time is 54s, and the temperature drops to 290°C; then it is transported to the air-cooling zone, the wind pressure is 1200Pa, and the cooling time is 66s , the height of the air grille is 25mm, and the temperature drops to 68°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com