High-stability low-cost preparation process of artificially synthesized mullite

A high-stability, artificial synthesis technology, applied in the field of mullite, can solve the problems of high cost, unstable product quality, and time-consuming, and achieve the effect of reducing the production energy consumption ratio, realizing the quality of the finished product, and stabilizing the quality of the finished product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

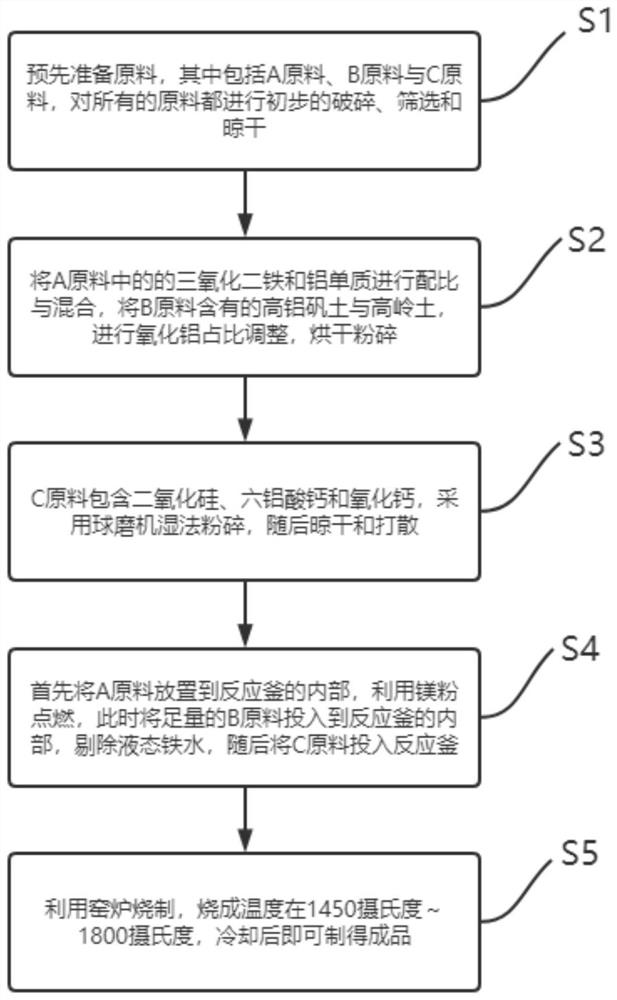

[0020] The present invention provides a technical solution: please refer to figure 1 , a high-stability and low-cost preparation process for artificially synthesized mullite, comprising the following steps:

[0021] Step 1: Prepare raw materials in advance, including raw materials A, raw materials B and raw materials C, and perform preliminary crushing, screening and drying on all raw materials.

[0022] Step 2, proportioning and mixing the ferric oxide and aluminum element in the A raw material, adjusting the alumina ratio of the high alumina bauxite and kaolin contained in the B raw material, drying and pulverizing.

[0023] Step 3. The raw material C contains silicon dioxide, calcium hexaaluminate and calcium oxide, which is wet pulverized by a ball mill, then air-dried and broken up.

[0024] Step 4: First, place the A raw material into the interior of the reactor, ignite with magnesium powder, and put a sufficient amount of the B raw material into the reactor at this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com