A high-efficiency double-layer multi-stage vibrating screen

A vibrating screen and double-layer technology, applied in the field of high-efficiency double-layer multi-stage vibrating screens, can solve the problems of unsatisfactory single-layer screening efficiency, low screening performance, and reduction, and achieve fast and stable secondary classification and screening, and realize reduction Vibration, to achieve the effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

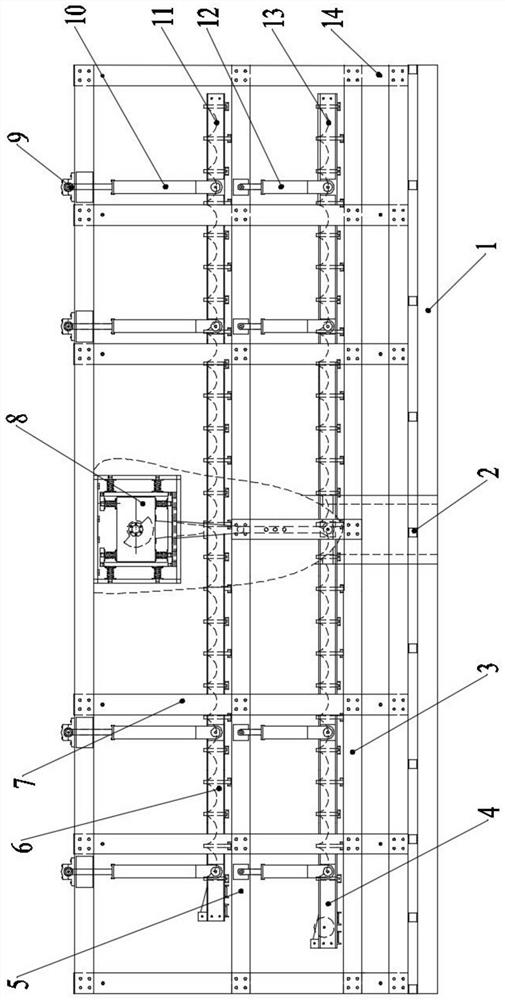

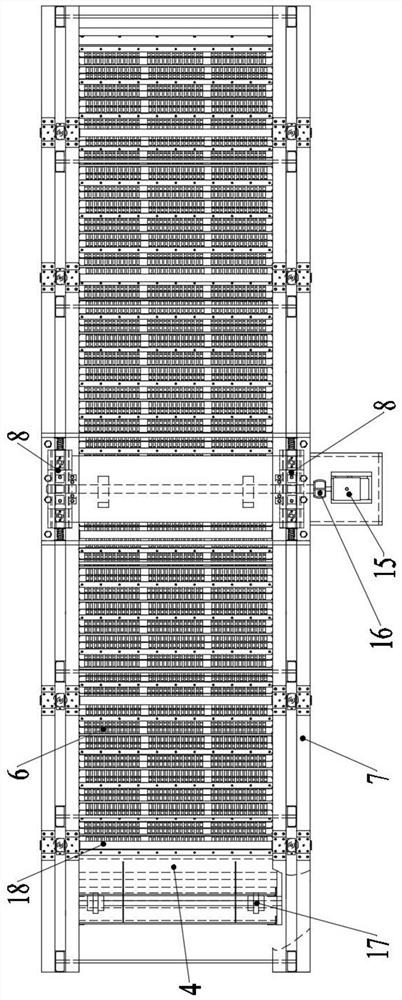

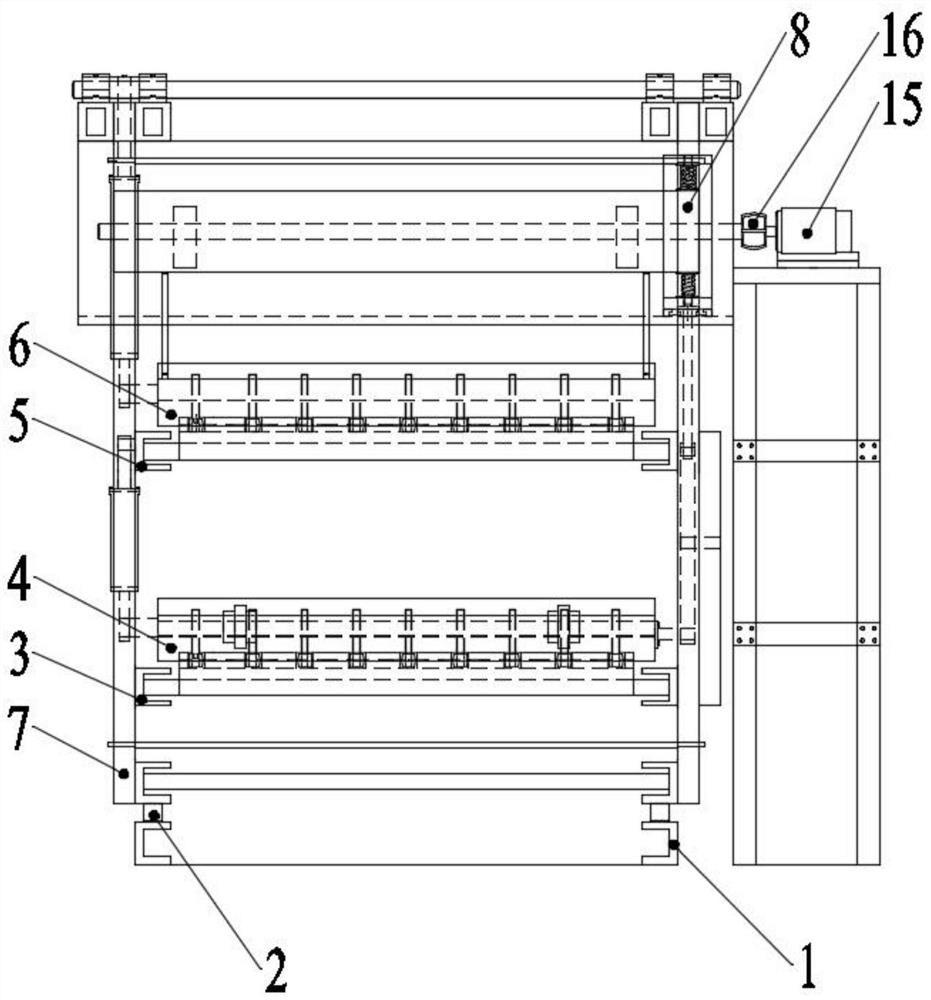

[0026] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as figure 1 The left-right direction is described as the front-back direction).

[0027] Such as Figure 1 to Figure 3 As shown, the high-efficiency double-layer multi-stage vibrating screen includes a base 1, a frame 7, an upper fixed screen box 5, an upper floating screen box 6, a lower fixed screen box 3, a lower floating screen box 4 and an exciting motion device 8.

[0028]The frame 7 is a frame structure including vertical beams 14 and crossbeams 18, and the frame 7 is positioned and installed on the base 1 through a plurality of vertically guided and telescopic shock absorbing spring groups 2 as a whole. The shock absorbing spring groups 2 can be It is a rubber spring flexible structure, and it can also be a rigid spring structure, preferably a rubber spring flexible structure; the upper fixed screen box 5 and the lower fixed screen box 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com