Magnesium, magnesium alloy and wastes thereof based production line for producing particle magnesium desulfurizing agent/particle magnesium alloy desulfurizing agent

A technology of granular magnesium and desulfurizer, applied in the direction of reducing gas emission, can solve the problems of unreasonable design of granulation cup, high maintenance cost, large energy consumption, etc., and achieve automatic control of the whole process, safe and reliable operation, and equipment structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

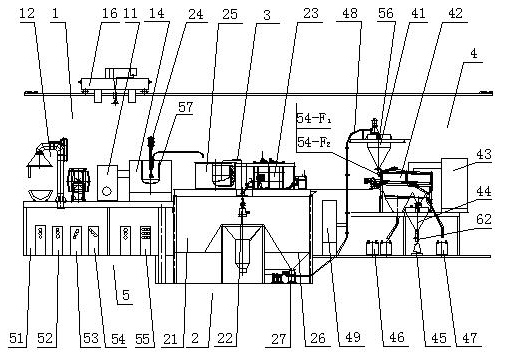

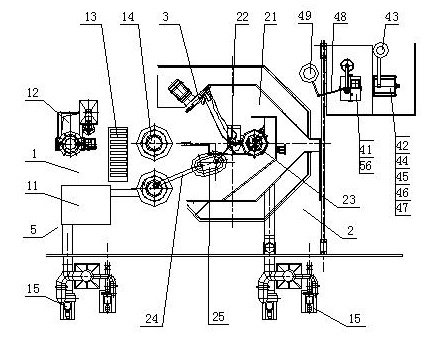

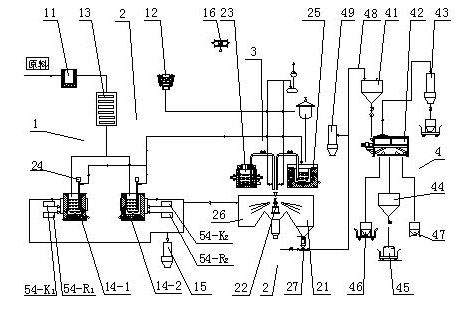

[0046] Referring to the accompanying drawings, a production line of granular magnesium desulfurizer / granular magnesium alloy desulfurizer based on magnesium, magnesium alloy and its waste materials, which mainly consists of raw material preheating and refining treatment system 1, granulation and ejection treatment system 2, vacuum The siphon system 3, the screening and finished product processing system 4, and the automatic control and operating system 5 are composed. The raw material preheating and refining processing system 1 includes a preheating oven 11 set on the left side of the front, and a crucible cleaning table 12 set on the right side of the front. , the feeding equipment 13 and the regenerative natural gas refining furnace 14 that are arranged in turn behind the crucible cleaning table 12, the granulation and ejection treatment system 2 includes a granulation chamber 21 arranged in the center, and a granulator 22 is arranged in the granulation chamber 21 , a salt fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com