Displacement chromatography hydrogen isotope separation device

A hydrogen isotope and separation device technology, which is applied in the separation of different isotopic elements, separation methods, and separation of dispersed particles, can solve the problems of high system construction and operation costs, high temperature control accuracy requirements, and short effective life of separation columns. Achieve the effects of low cost, low precision requirements, and low energy consumption ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

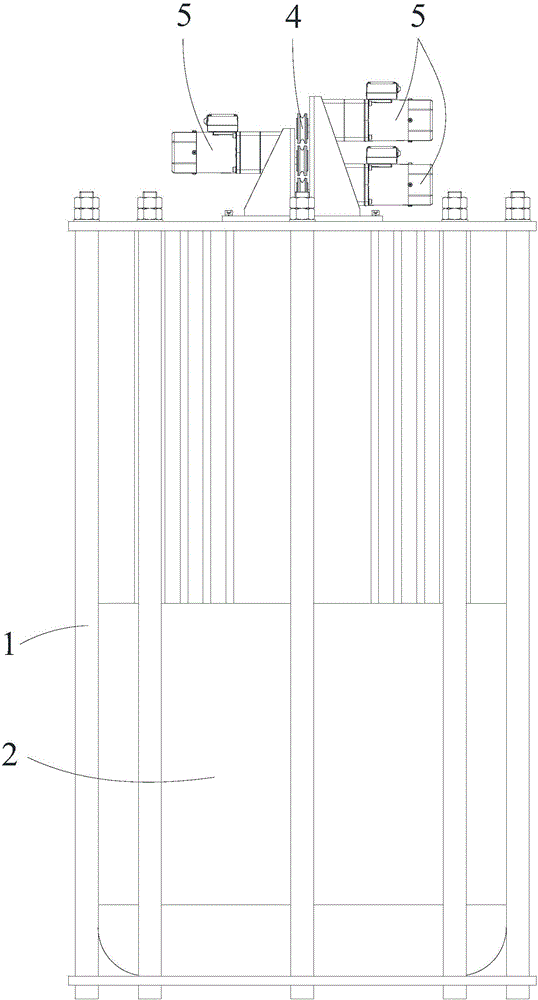

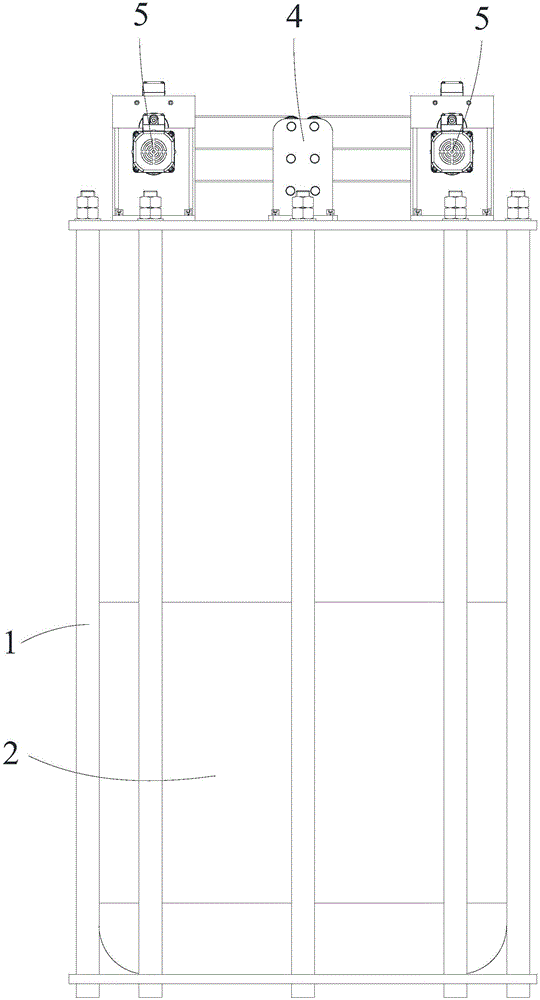

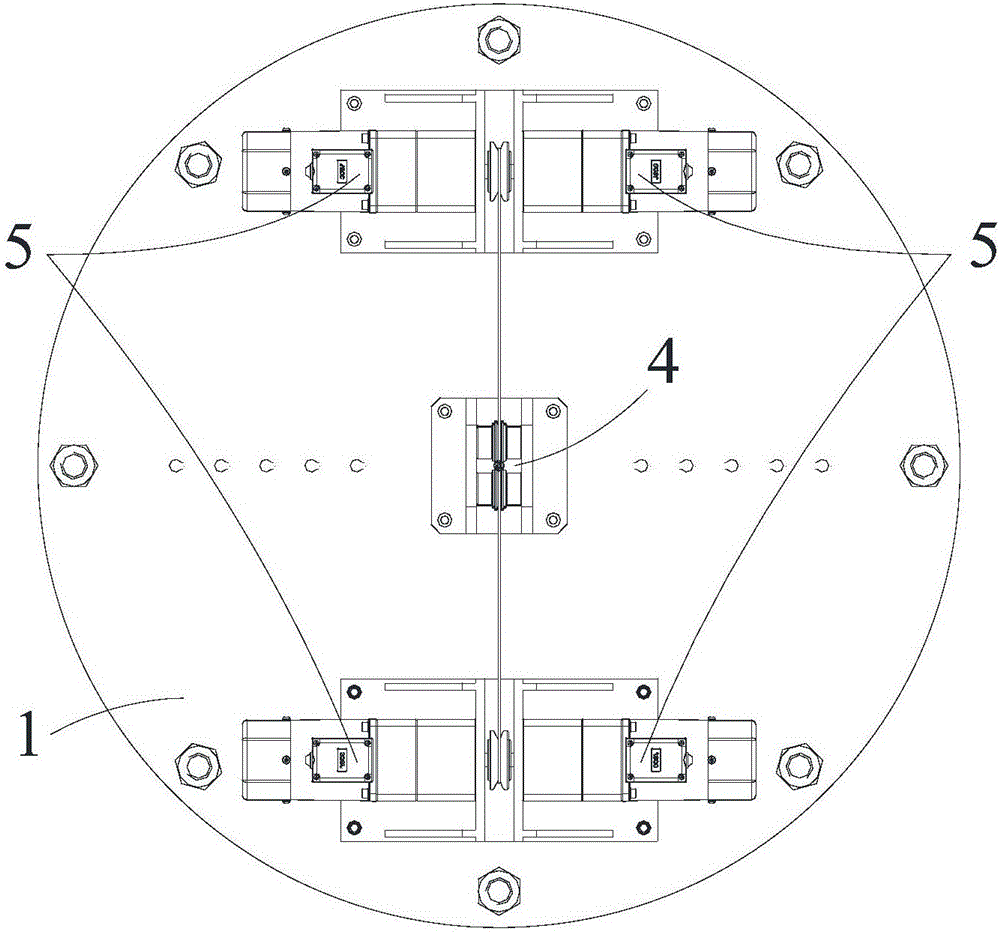

[0053] Such as Figure 1-4 As shown, a displacement chromatographic hydrogen isotope separation device according to the present invention includes a frame 1, a cooling part 2, six separation columns 3, a gas supply part, a gas collection part, a lifting part 4, a driving part 5 and a limit Part 6.

[0054] The cooling unit 2 is arranged on the frame 1 and includes a container, the container is used to hold liquid nitrogen, and a switch is provided on the container, and the switch is used to control the liquid nitrogen to enter and exit the container;

[0055] Each separation column 3 is vertically arranged, and each separation column 3 includes a hollow tube, the lower end of the hollow tube is closed and arranged, the upper end of the tube is connected to a multi-way valve, and a 5A molecular sieve is arranged inside it. The 5A molecular sieve is used to absorb hydrogen gas when each separation column 3 is immersed in liquid nitrogen, and desorb protium, deuterium or tritium...

Embodiment 2

[0066] Such as Figure 5 As shown, a displacement chromatographic hydrogen isotope separation device according to the present invention includes a frame 1, a cooling part 2, six separation columns 3, a gas supply part, a gas collection part, a lifting part 4, a driving part 5 and a limit The component 6 is different from the embodiment 1 in that it further includes a heating component 7 .

[0067] The cooling unit 2 is arranged on the frame 1 and includes a container, the container is used to hold liquid nitrogen, and a switch is provided on the container, and the switch is used to control the liquid nitrogen to enter and exit the container;

[0068] Each of the separation columns 3 is vertically arranged, and each of the separation columns 3 includes a hollow tube. The lower end of the hollow tube is closed and arranged, and the upper end of the tube is connected to a multi-way valve. , the content of Pd in the palladium-loaded alumina is 30%w.t, and its particle diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com