Bidirectional bell and spigot clad pipe based on enhanced steel skeleton and process for producing clad pipe

A reinforced, composite pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as socket and socket cannot be interchanged, leakage at socket joints, difficult butt joint quality, etc., to achieve light weight, The effect of enhanced rigidity of the socket ring and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

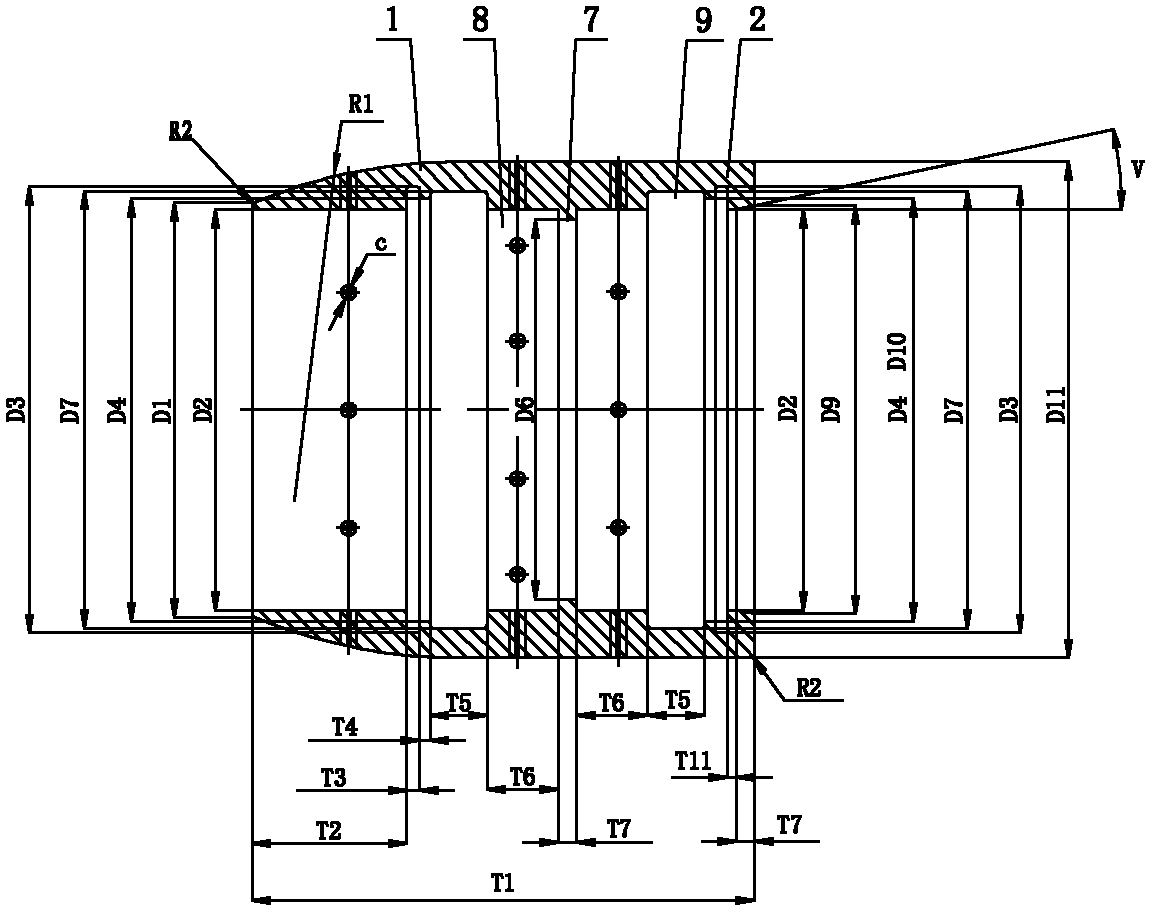

[0088] Table of main dimensions and parameter values of the embodiments of the present invention.

[0089] Table 1 is a value table of main radial dimensions of the present invention.

[0090] Table 2 is a value table of main axial dimensions of the present invention.

[0091] Table 3 is a comprehensive size value table of the present invention.

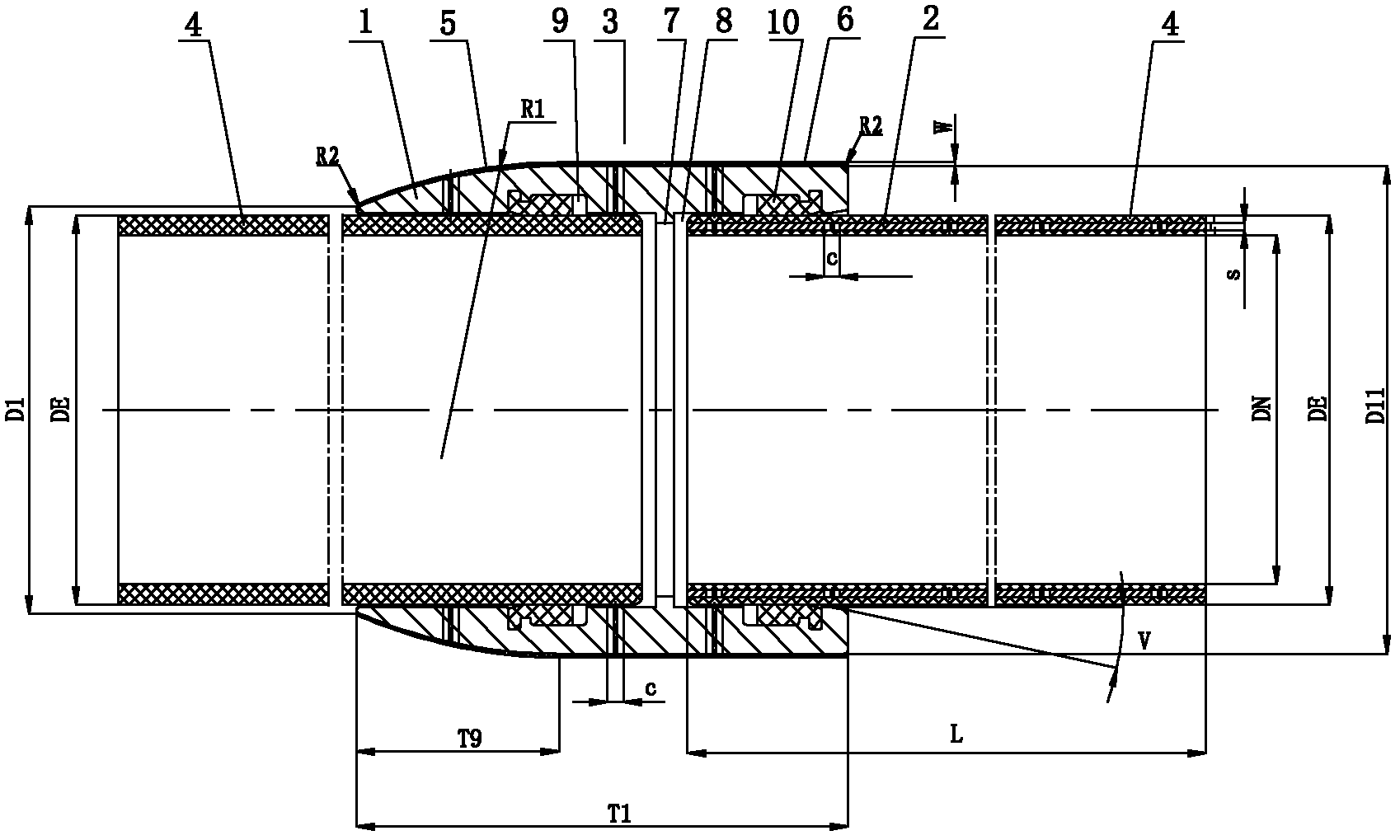

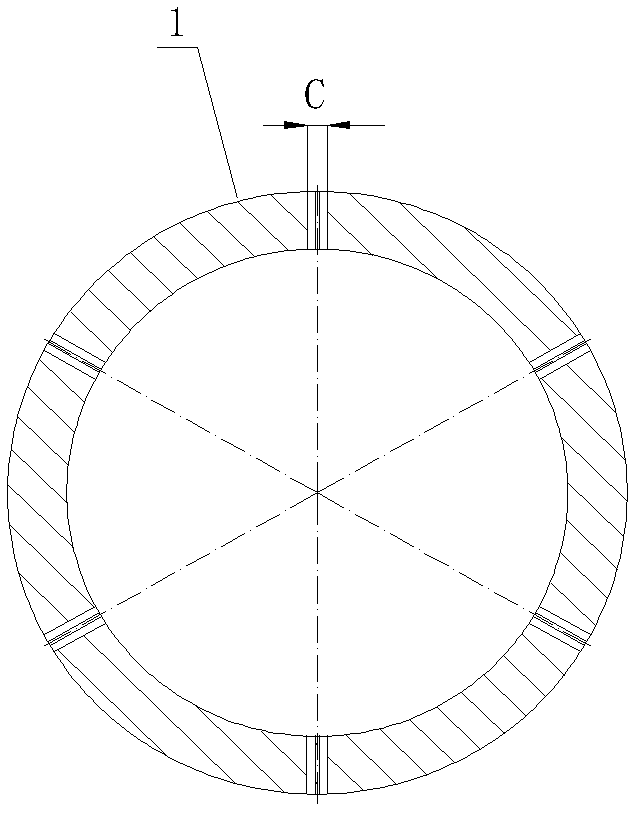

[0092] Referring to the accompanying drawings and tables, a composite pipe based on a reinforced steel skeleton with two-way socket socket includes a main skeleton 1 and an auxiliary skeleton 2 made by casting or stamping technology, and socket sockets are respectively made by injection molding and spray molding technology. The main pipe 3 and the socket auxiliary pipe 4 are adapted and connected, assembled into a socket composite pipe and subjected to protective treatment before being installed and used on site.

[0093] As shown in the accompanying drawings and tables, a composite pipe based on a steel frame reinforced bidirect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corner radius | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com