Water tank structure of heat exchange water tank

A technology for exchanging water tanks and water tanks, which is applied to the types of heat exchangers, indirect heat exchangers, heat exchange equipment, etc., which can solve the problems of low heat transfer efficiency, long pipe length, and high cost, so as to increase fluid resistance, The effect of saving production cost and efficient heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

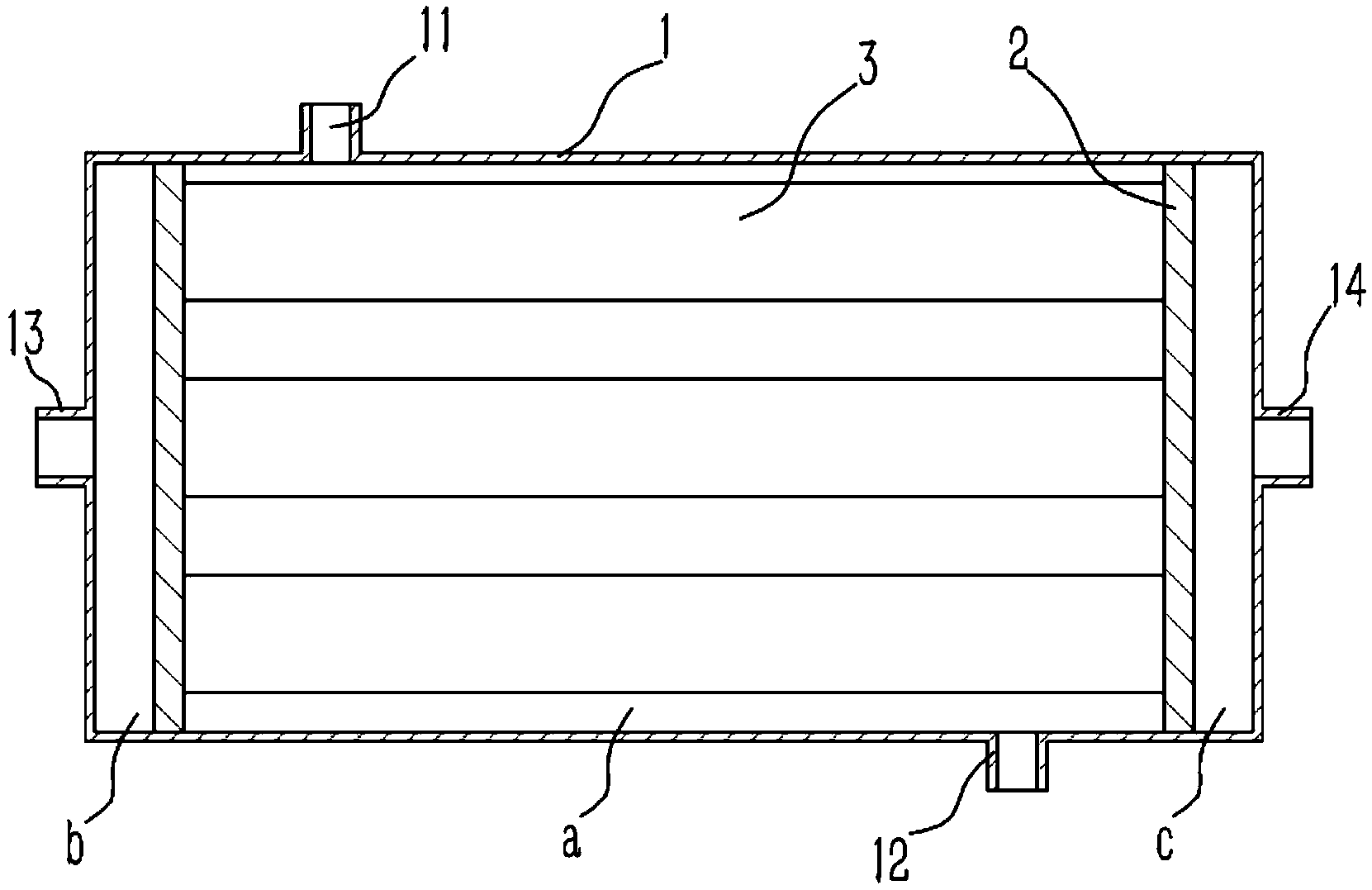

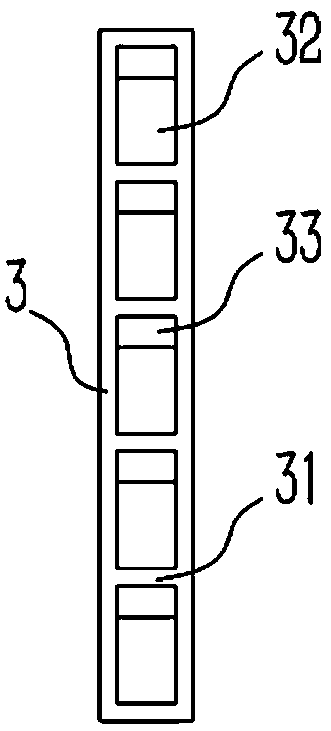

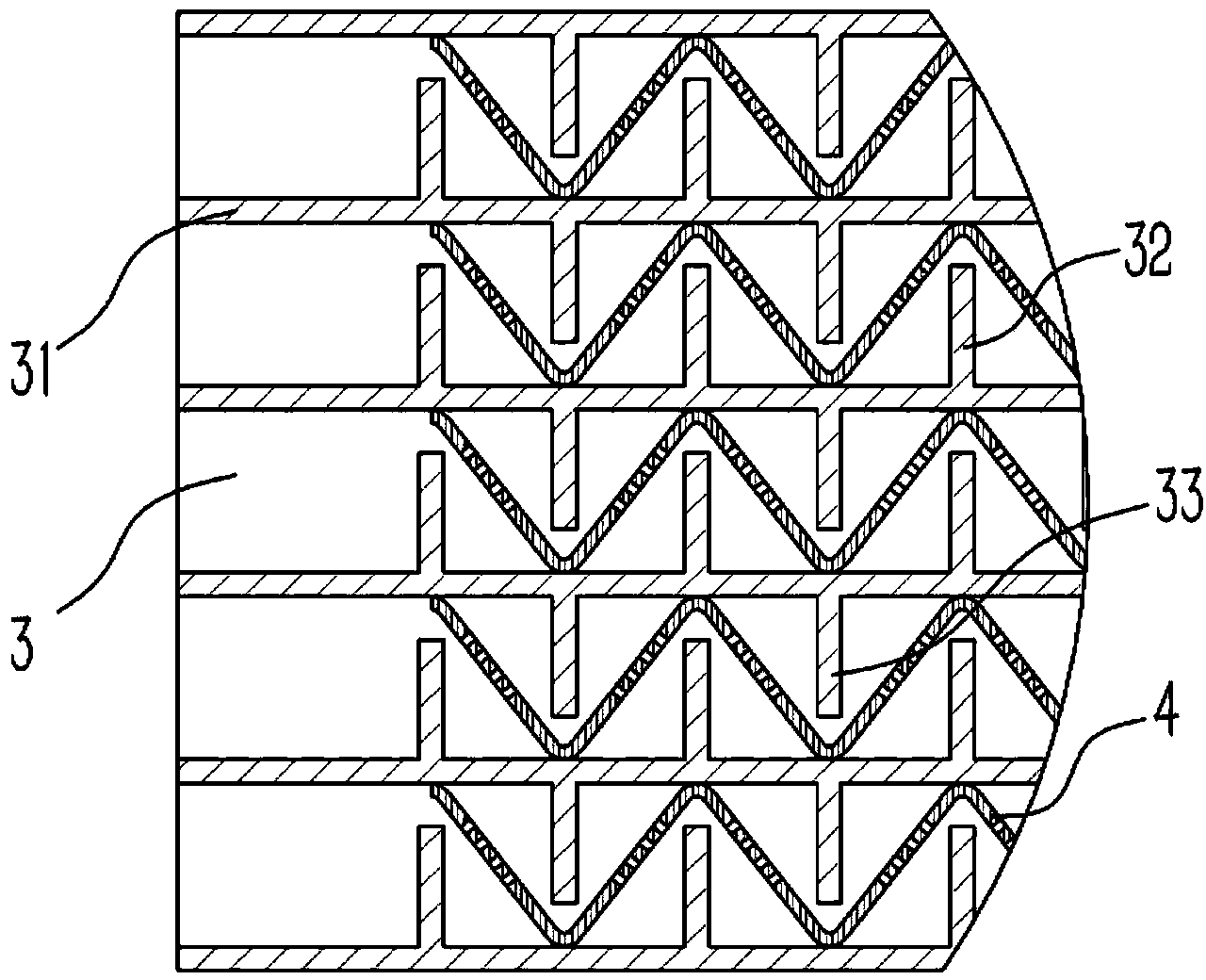

[0015] Example: see figure 1 , 2 , 3, a water tank structure of a heat exchange tank, including a rectangular flat water tank 1, the upper and lower ends of the flat water tank 1 are respectively formed with a water inlet 11 and a water outlet 12, and two sealing partitions 2 are fixed in the flat water tank 1 , the sealing partition 2 separates the inner cavity of the water tank into a refrigerant inlet chamber b, a water storage chamber a, and a refrigerant outlet chamber b, and the side walls of the flat water tank 1 where the refrigerant inlet chamber b and the refrigerant outlet chamber b are located are respectively formed with refrigerant Inlet 13 and refrigerant outlet 14, several rectangular heat dissipation pipes 3 are distributed in the water storage chamber a, and the two ends of the heat dissipation pipes 3 are respectively welded and fixed on the two sealing partitions 2 and connected with the refrigerant inlet chamber b and the refrigerant outlet The liquid cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com