Wet treater

A technology for wet processing and cleaning, applied in optics, instruments, electrical components, etc., to achieve the effect of improving suction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

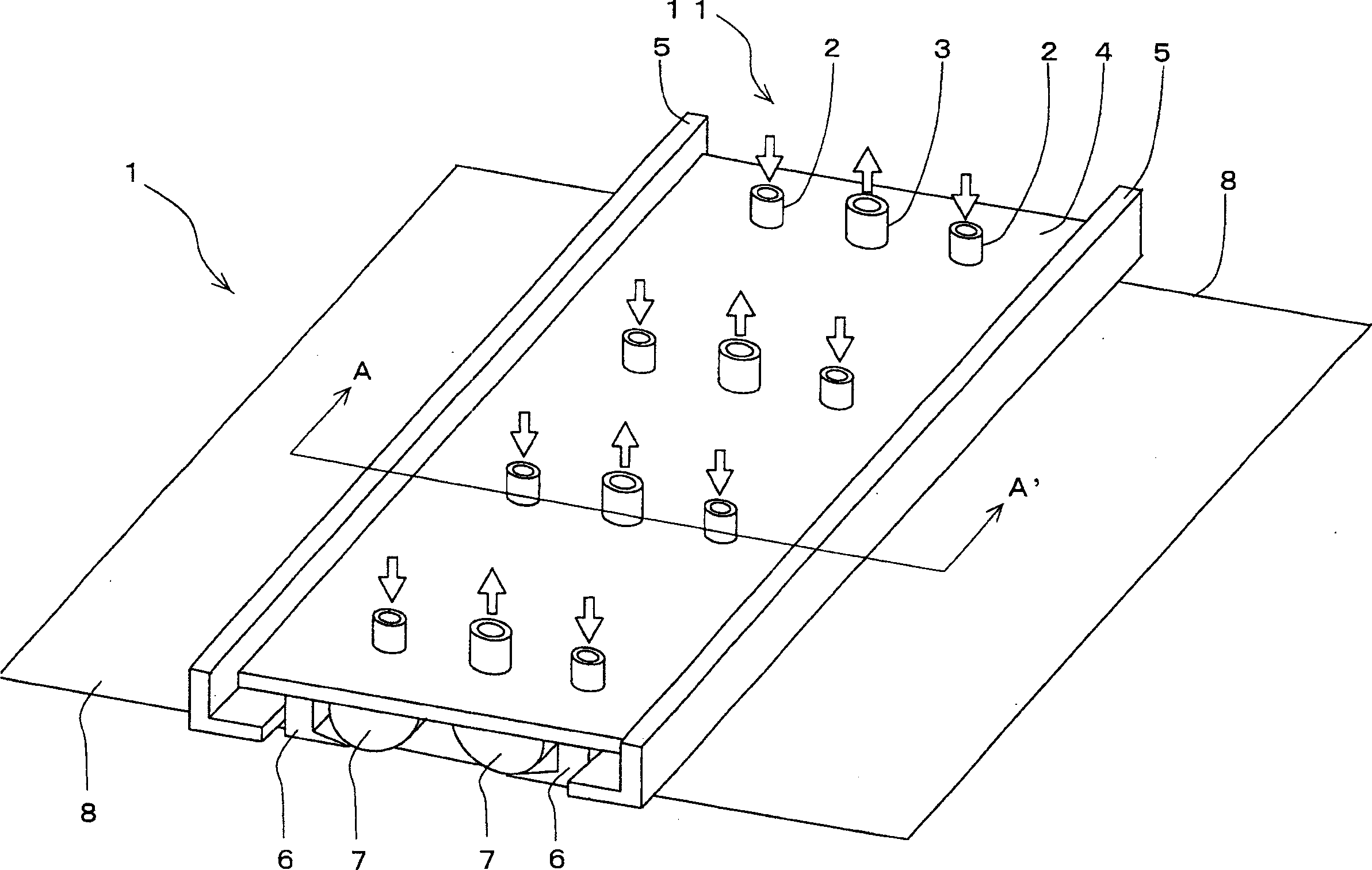

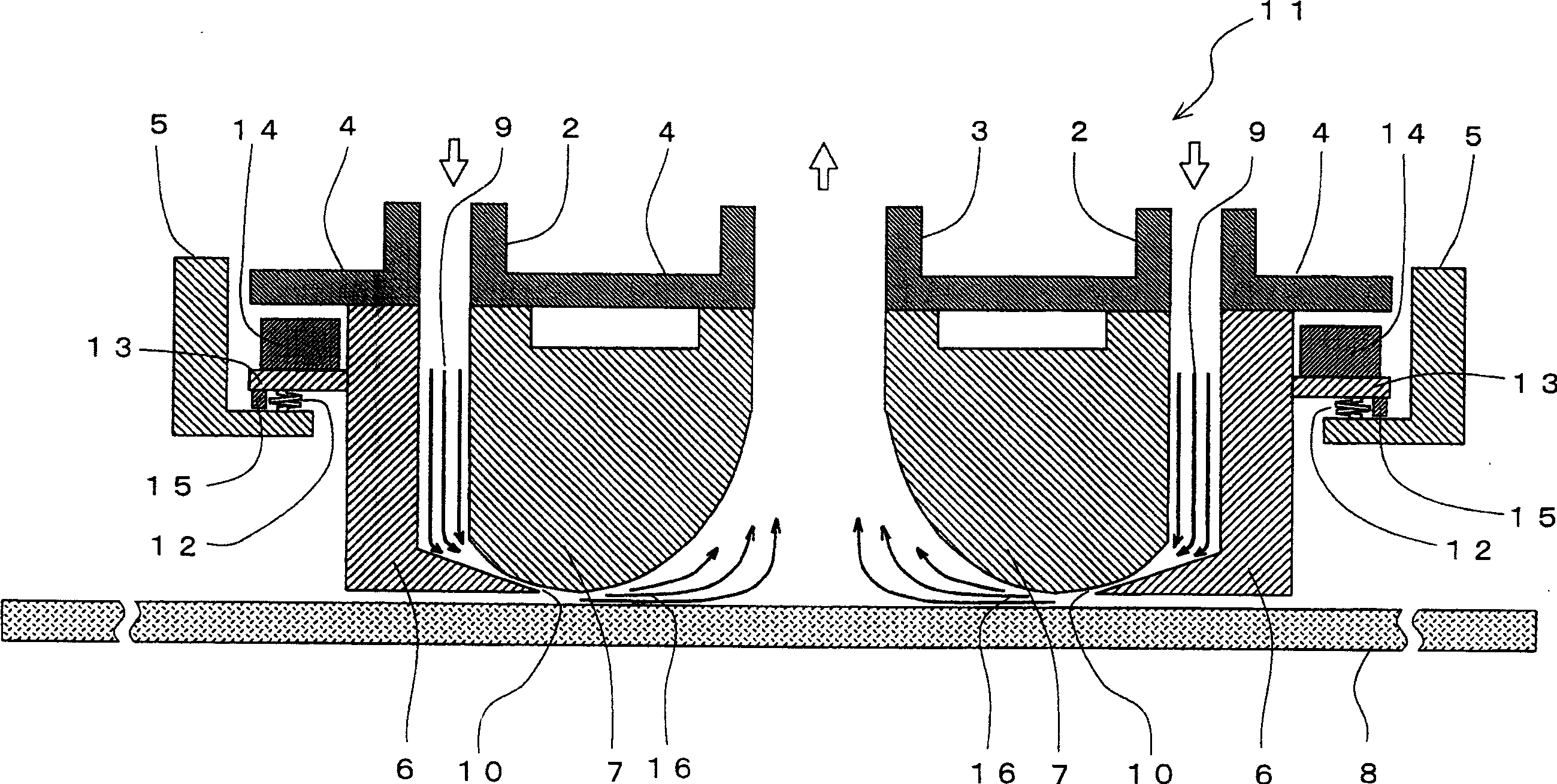

[0054] figure 1 It is a perspective view of the appearance of the cleaning unit of Embodiment 1 of the wet processing device of the present invention. in addition, figure 2 yes figure 1 A-A' sectional view of the cleaning assembly shown. exist figure 1 and figure 2 Among them, the wet processing device 1 of Embodiment 1 is disposed close to the top of the object 8 to be cleaned, and has a slit-shaped opening for discharging the strip-shaped cleaning fluid 9 onto the surface of the object 8 to be cleaned. Spit out 10. The discharge port 10 is arranged left and right, and is equipped with the supply port 2 of the two above-mentioned cleaning fluids 9 having the opposite discharge port 10 arranged symmetrically with respect to the discharge port 3 and the fluid jet liquid 16 ejected from the above-mentioned relative discharge port 10. The cleaning assembly 11 constituted by the discharge port 3 through which the cleaning fluid 9 is discharged.

[0055] The above-menti...

Embodiment 2

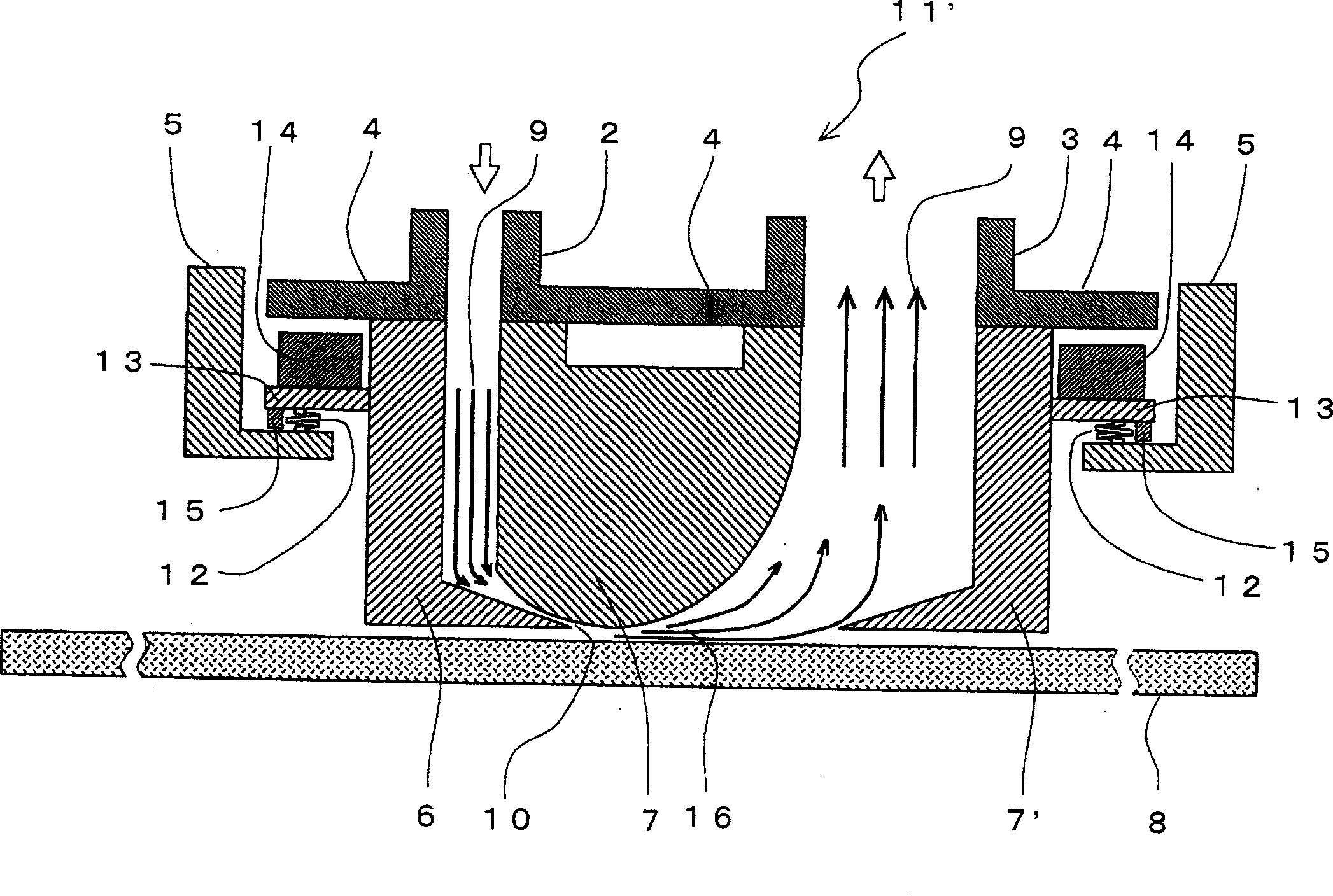

[0076] image 3 It is a cross-sectional view of the cleaning unit of Example 2 of the wet processing apparatus of the present invention. In embodiment 2, it does not have any one of the supply ports 2 arranged left and right in embodiment 1 and has the opposite discharge port 10 symmetrically arranged with respect to the discharge port 3, and has a cleaning unit 11 each having one supply port and one discharge port. '. The above-mentioned cleaning assembly 11' is characterized in that it has a slit-shaped opening that is arranged close to the top of the object to be cleaned 8 and is configured to discharge the strip-shaped cleaning fluid 9 onto the surface of the object to be cleaned 8. The cleaning assembly 11' constituted by the discharge port 3 through which the cleaning fluid of the fluid ejection liquid 16 discharged from the discharge port 10 is discharged. , the front end portion at which the cleaning fluid 9 is ejected toward the surface of the object 8 to be cleaned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com