Manufacturing method of luminescent device, luminescent device, and display device

A manufacturing method and a technology of light-emitting devices, which are applied in the field of quantum dot light-emitting, can solve the problems that light-emitting devices are difficult to prepare multi-layer quantum dot films, and achieve high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0042] The invention provides a solution to the problem that it is difficult to prepare multi-layer quantum dot thin films in the existing manufacturing methods of light-emitting devices.

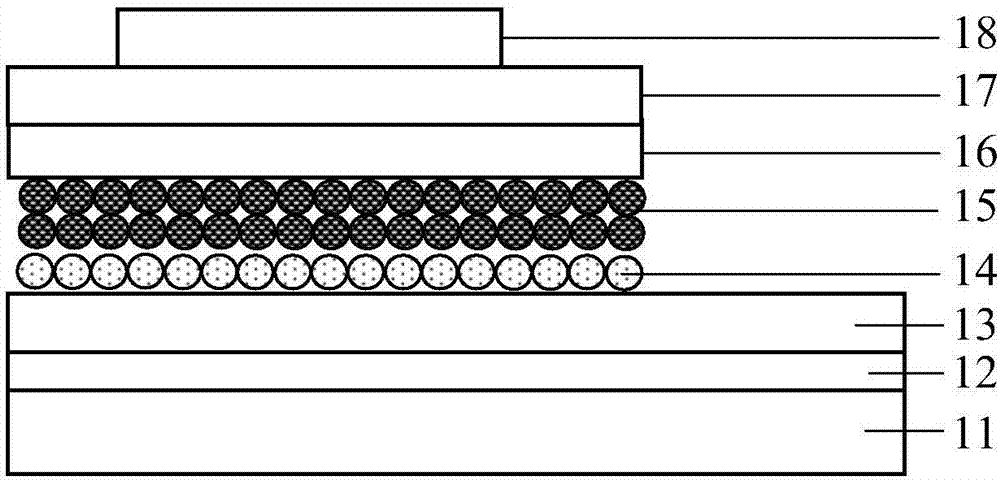

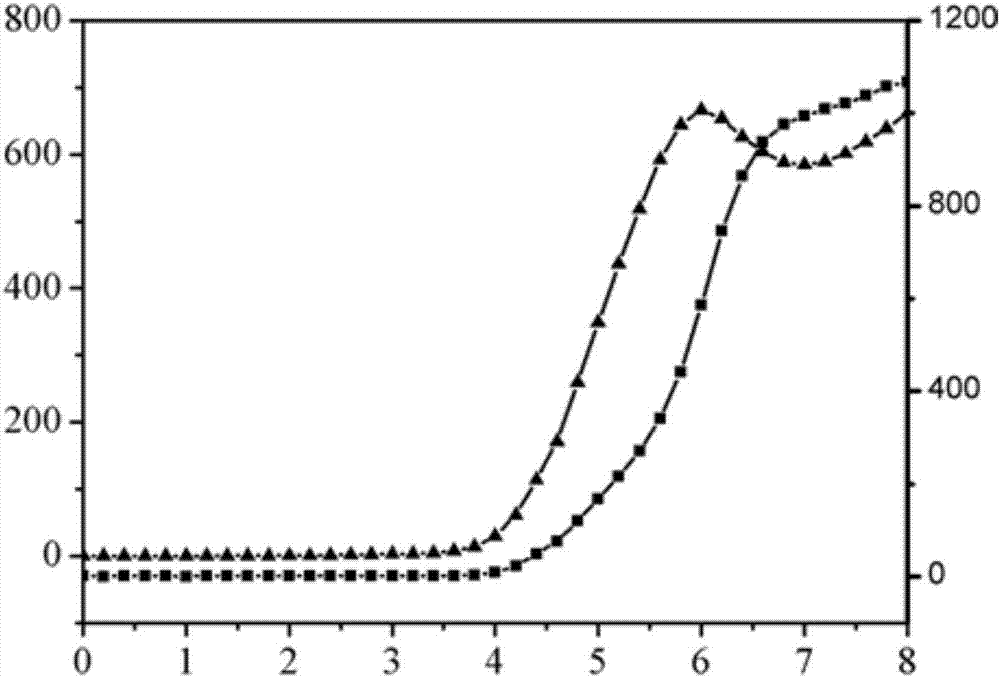

[0043] On the one hand, an embodiment of the present invention provides a method for manufacturing a light-emitting device, including: forming an electron injection layer, an electron transport layer, a light-emitting layer, a hole transport layer, a hole injection layer, and an electrode on a substrate.

[0044] Among them, different from the prior art, the step of forming the light-emitting layer in this embodiment includes:

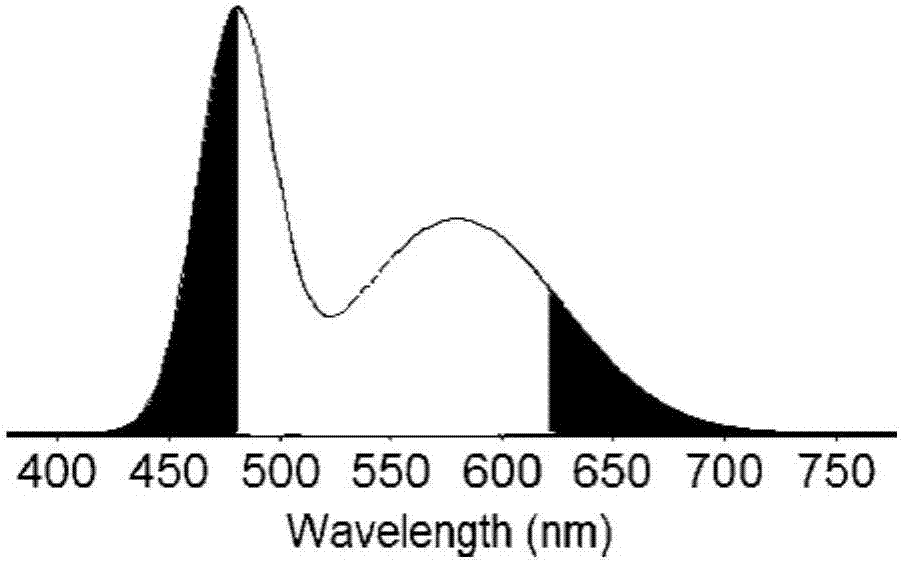

[0045] A variety of different quantum dot solutions are sequentially deposited on the substrate to form a stack of multiple layers of differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com