An ito glass spin-coating black glue system device based on positioning analysis

A system device and glass spin coating technology, applied in the field of LCD processing and production technology devices, can solve the problems of deviation, uneven black film of ITO glass plate, affecting the qualification rate of process operation products, etc., to ensure stability and uniform black film spin coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

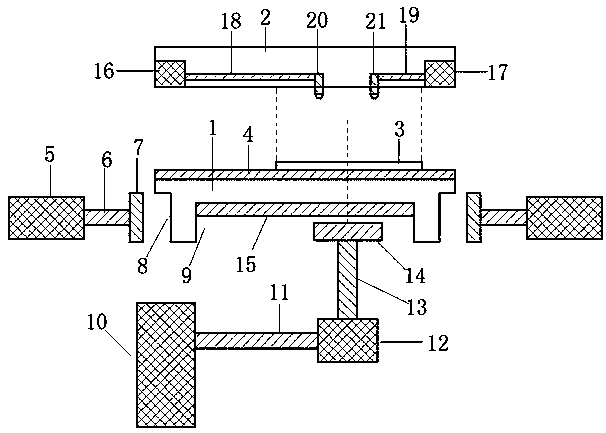

[0021] The present invention is an ITO glass spin-coating black glue system device based on positioning analysis, including a rotating platform 1, the upper surface of which is embedded with a pressure sensing layer 4; the ring side of the rotating platform 1 is provided with a side groove 8 structure; The bottom side of the rotating platform 1 is provided with a floor groove 9 structure.

[0022] It includes a pair of first telescopic devices 5, the first telescopic devices 5 are located on both sides of the rotating platform 1; it includes a second telescopic device 10 and a power device 12, and the second telescopic device 10 is connected to the power device 12; it includes an adsorption plate 14 structure , the power unit 12 is connected with the adsorption plate 14 .

[0023] Including the first support mechanism 2, the first support mechanism 2 is fixed with the third telescopic device 16 and the fourth telescopic device 17; includes the first black glue dropper 20 and t...

specific Embodiment 2

[0031] Such as figure 1 As shown, when the ITO glass 3 is placed on the rotary platform 1, the pressure sensing layer 4 senses the position of the ITO glass 3; the first telescopic device 5 drives the clamping plate 7 to support the rotary platform 1; the second telescopic device 10 Drive and adjust the power unit 12 to adjust the position; the adsorption plate 14 and the electromagnetic panel 15 are separated and closed by electromagnetic action; the third telescopic device 16 on the first support mechanism 2 drives and adjusts the position of the first vinyl dropper 20 The location, the fourth telescopic device 17 on the first support mechanism 2 drives to adjust the location of the second black glue dropper 21, so as to facilitate the corresponding glue dropping operation on the ITO glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com