Diamond with cantilever structure and preparation method thereof

A diamond and cantilever technology, which is applied in the field of diamond with cantilever structure and its preparation, can solve the problem that complex structures cannot be prepared

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

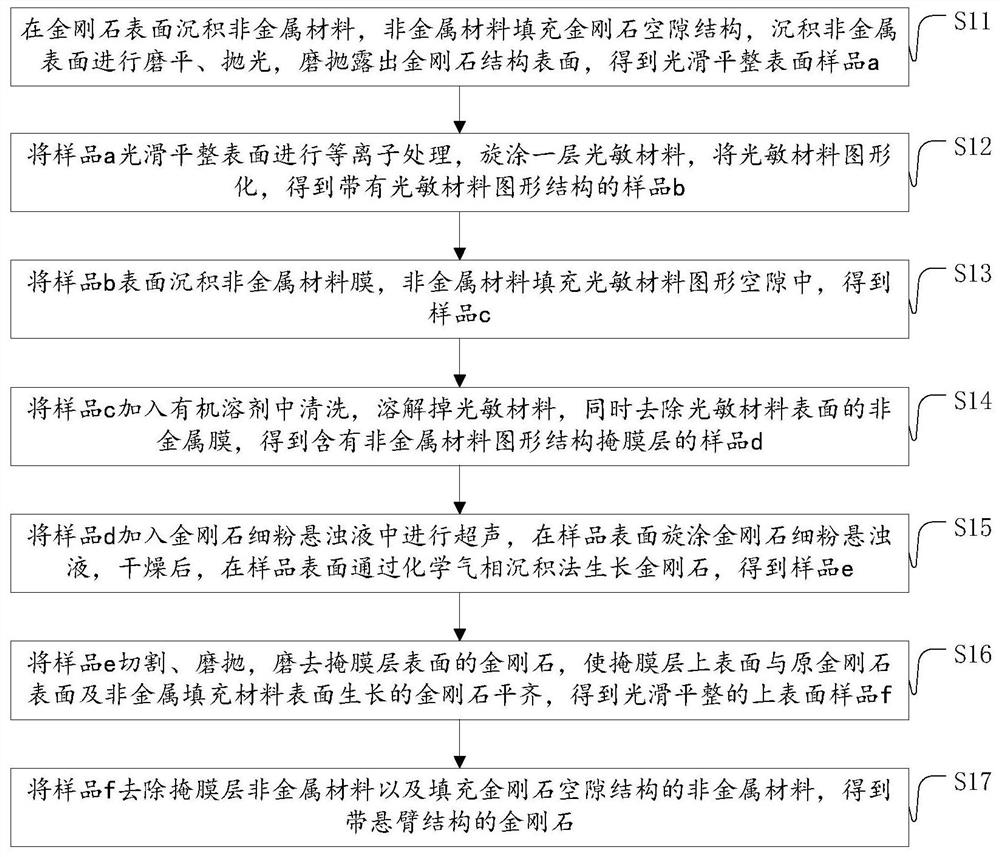

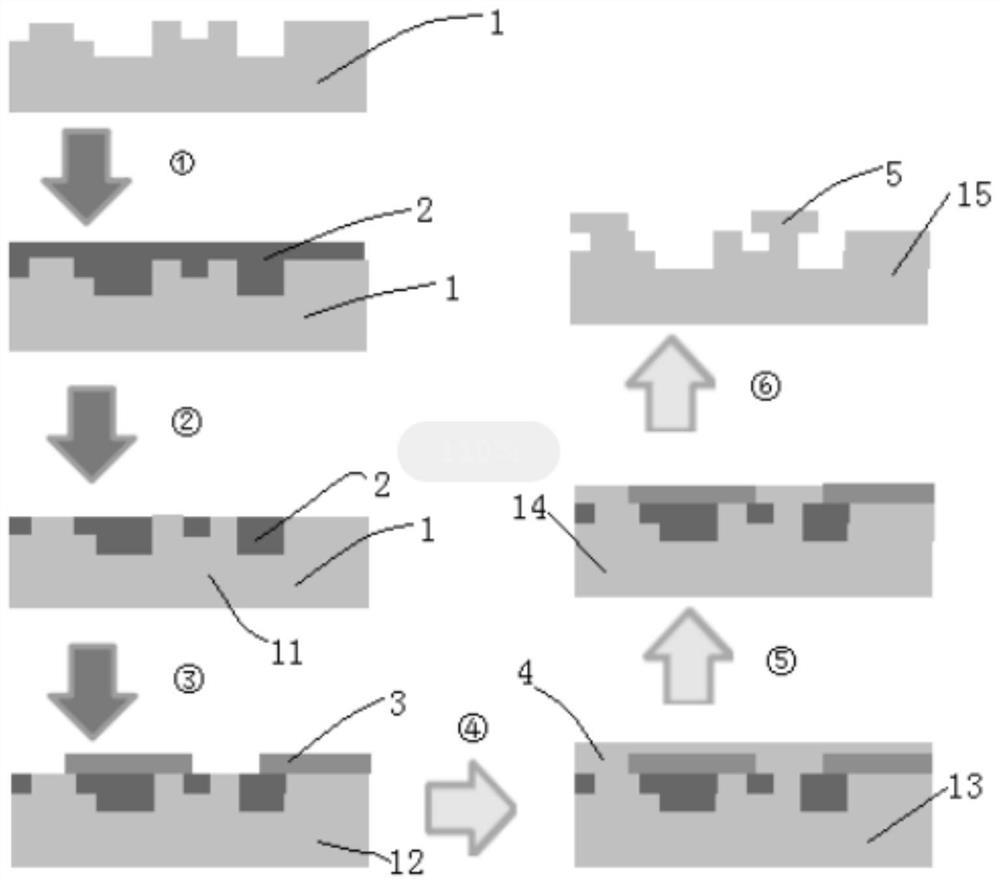

[0043] Please see figure 1 , a diamond with a cantilever structure and a preparation method thereof, the method comprising:

[0044] S11. Deposit non-metallic materials on the surface of diamond, fill the void structure of diamond with non-metallic materials, deposit non-metallic surface for grinding and polishing, and grind and polish to reveal the surface of diamond structure to obtain a smooth and flat surface sample a; in single-layer structure diamond or multi-layer On the surface of diamond with ladder structure, non-metallic materials are deposited on the first surface of diamond by sputtering or evaporation deposition method. Using diamond micropowder as a grinding and polishing material for fine grinding and polishing, the upper surface of the diamond structure is exposed by grinding and polishing, and a smooth and flat surface sample a is obtained. Among them, the non-metallic material is one of silicon dioxide, silicon, silicon carbide and silicon nitride, and sili...

specific Embodiment

[0061] Take 5 polycrystalline diamond sheets of 5mm*5mm*1mm, numbered G1, G2, G3, G4 and G5 respectively. The period of the polycrystalline diamond sheet prepared by nanoimprinting, coating, and plasma etching is 1um and the depth is 100nm. groove structure;

[0062] Deposition of 150 nm thick SiO on the surface of diamond samples with grooved structure by magnetron sputtering 2 layer;

[0063] Grinding and polishing the surface of the sample to expose the upper surface of the diamond, so that the SiO 2 The layer is flush with the upper surface of the diamond structure. Among them, the G1 sheet sample was ground and polished by ordinary grinding and polishing methods, and SiO 2 The layer is easily broken; in addition, the four pieces of G2, G3, G4 and G5 can avoid the cracking of the SiO2 layer by using diamond powder as the grinding material and using the cast iron disc to adopt an extremely low grinding rate;

[0064] Spin-coat a layer of PMMA photosensitive material on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com