Adjustment and application method for tilting compensation control of lens of automatic focusing camera module

A technology of compensation control and debugging method, which is applied in the direction of cameras, optics, instruments, etc., can solve the problems of excessive production errors such as static and dynamic tilt angles, reduce static and dynamic tilt angles, reduce operating costs, and save space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

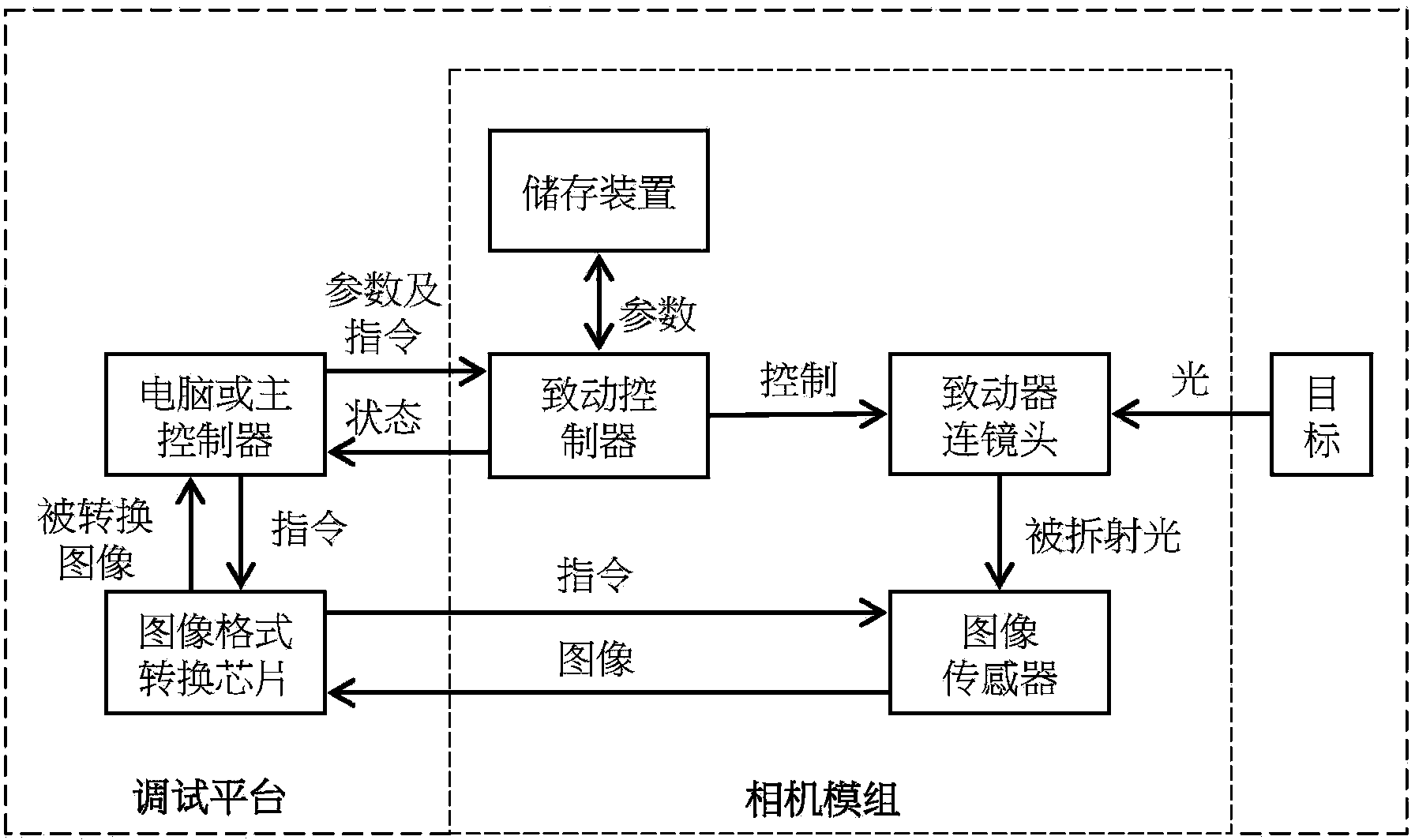

[0029] Please see attached figure 1 , the hardware system based on the present invention mainly includes two parts: a camera module and a debugging platform, wherein the debugging platform includes a computer or a main controller and an image format conversion chip, wherein the computer or a main controller (for example: Cortex A Series) must Can read the image, and have enough computing power, can quickly analyze the image, and have a storage medium for storing parameters, and can issue instructions to the actuation controller, and the image format conversion chip can change the image format of the image sensor to an available The format read by the computer or the host controller, for example: change to a USB image format for the computer to rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com