Synthetic blown insulation

A technology for isolating materials and mixtures, applied in the directions of loose fill materials, thin material processing, decorative textiles, etc., which can solve the problems of slow, cumbersome batch methods of clusters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

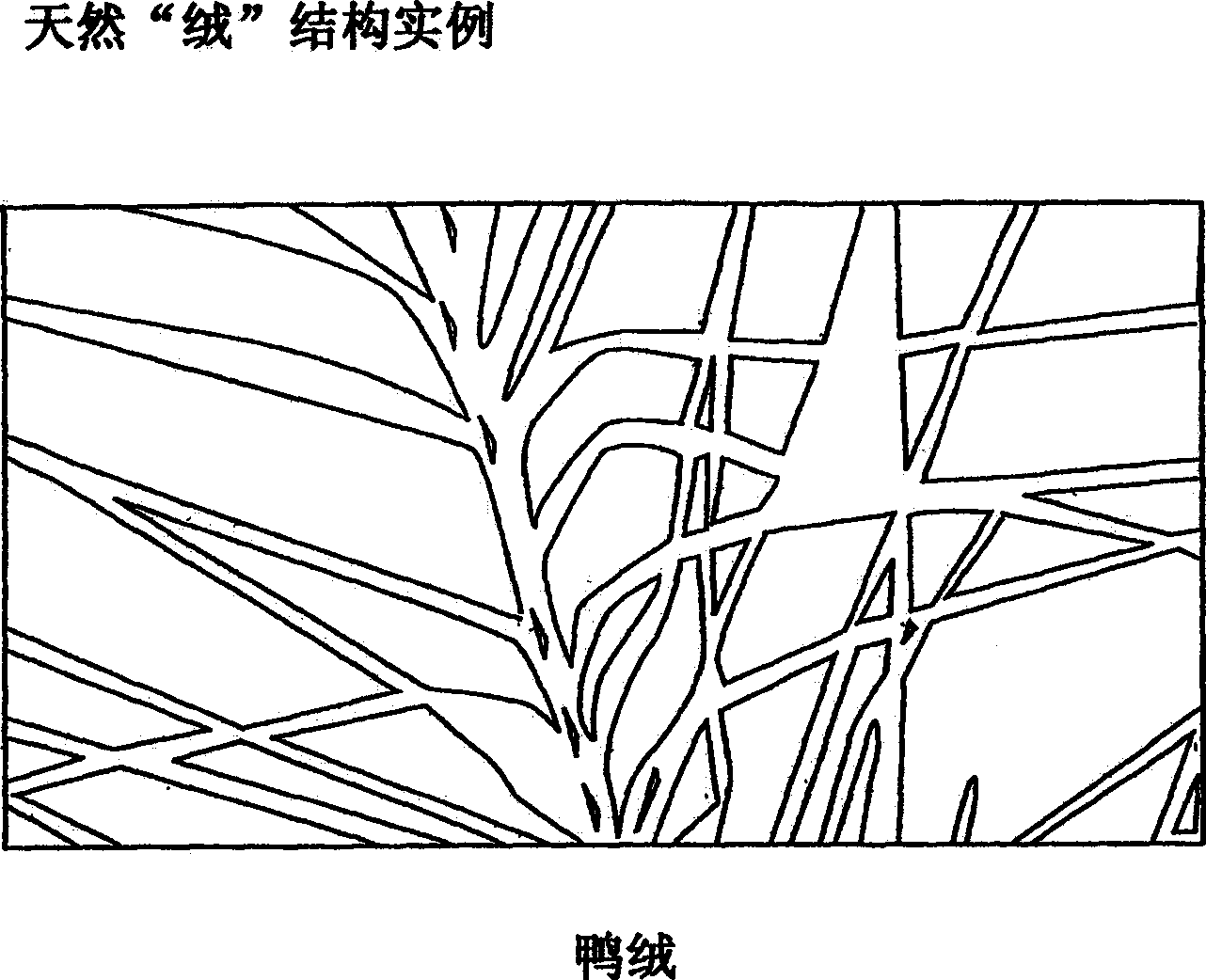

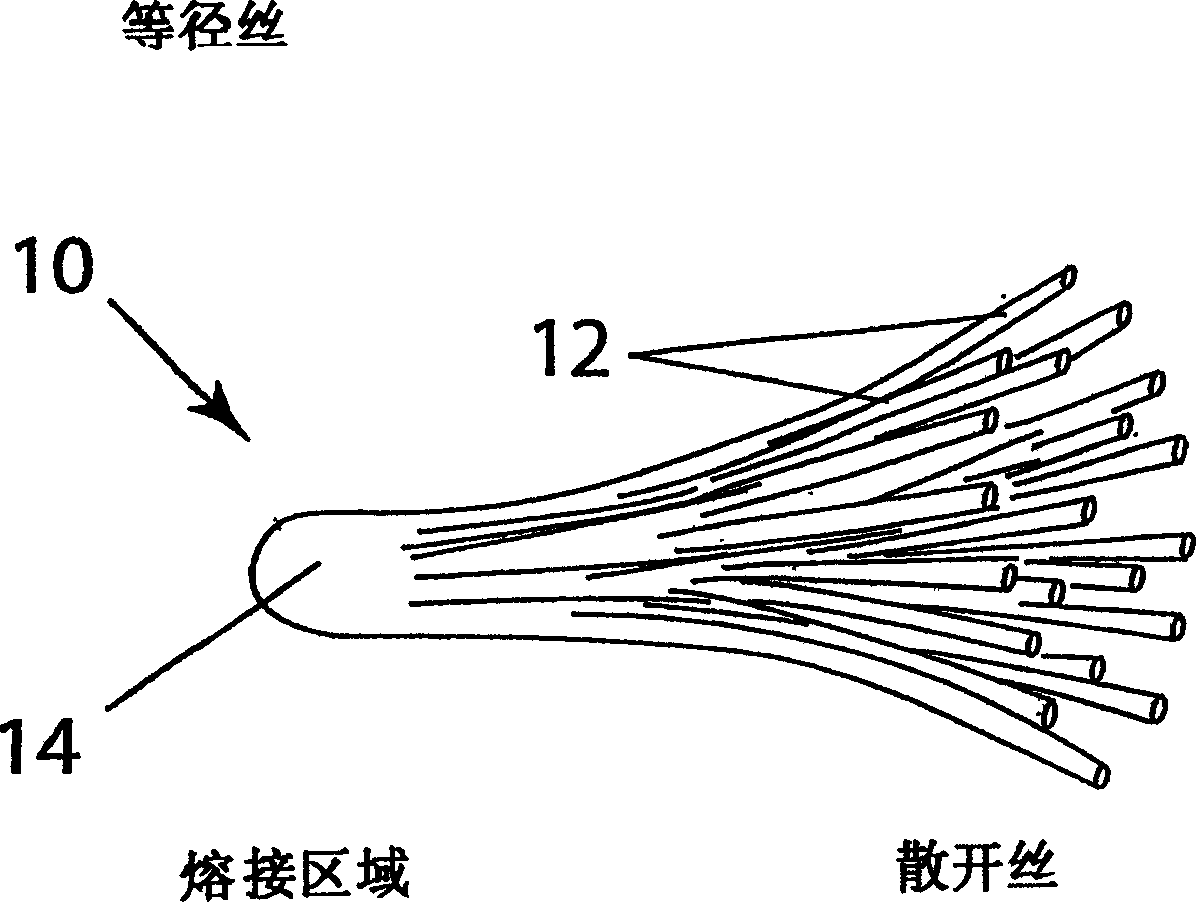

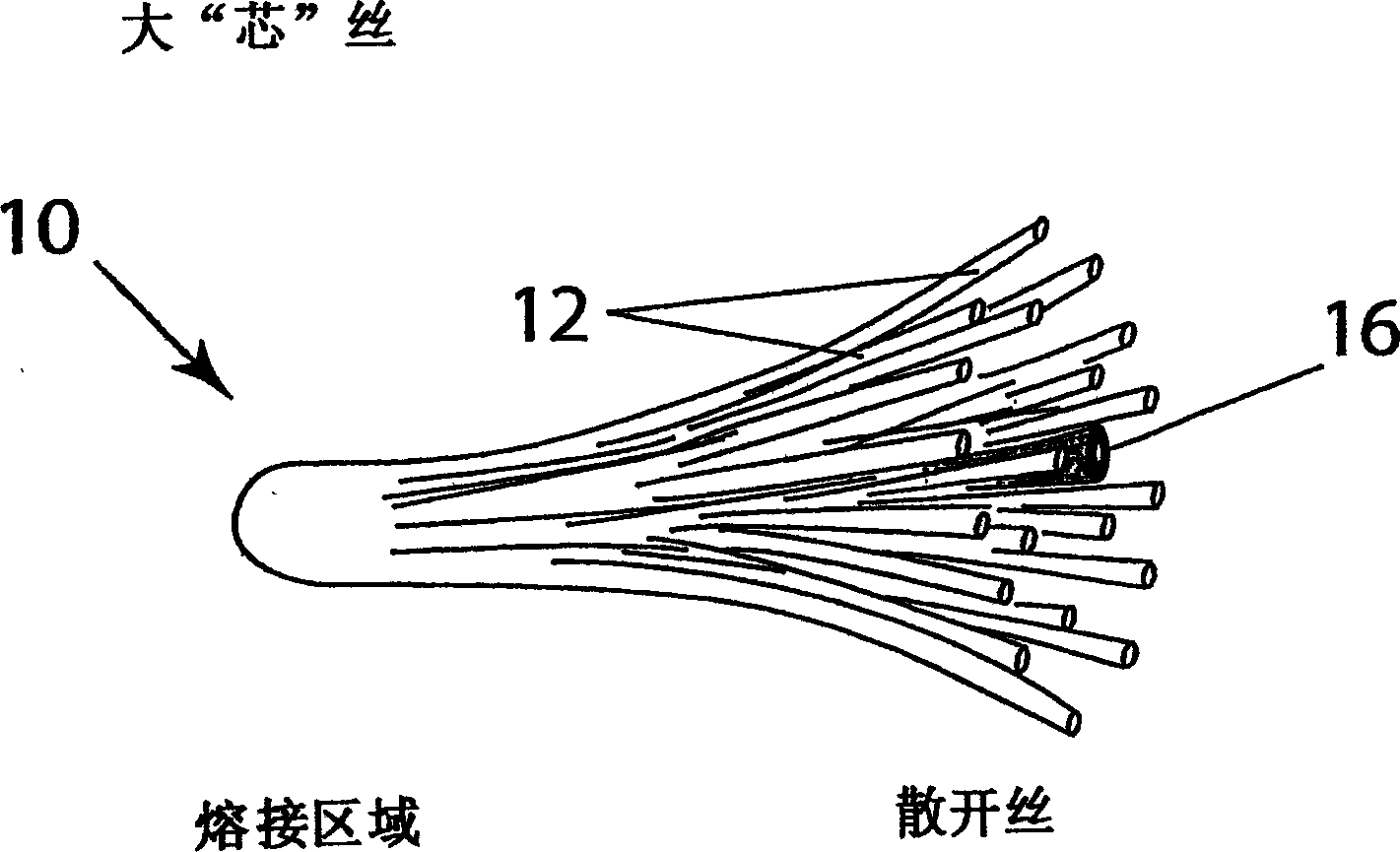

[0035] With specific reference now to the accompanying drawings, Figure 2A Schematically showing the release material of the invention in a disintegrable form. The isolation structure 10 comprises a plurality of individual filaments 12 joined or welded at one end 14 and fanned out at the opposite end. In other words, the isolation material 10 contains similar figure 1 The fir tree-like structure or tree-like structure of the natural down fiber structure shown.

[0036] In this regard, if Figure 2A As shown, the isolation structure 10 has filaments 12 that can all be of equal diameter, or otherwise as Figure 2B As shown, a core 16 of filaments having a larger diameter is surrounded by a plurality of open filaments 12 of smaller diameter. Furthermore, the number and length of the filaments 12, 16 may vary. In addition, if Figure 2A and Figure 2B As shown, the isolation structure 10 can have straight filaments, or have coiled filaments (not shown in the figure).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com