Device and method for wet treating laundry

a technology for wet treatment and laundry, applied in the direction of washing machines with receptacles, washing apparatus, applications, etc., can solve the problems of limited quantity and known devices that have proven problemati

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

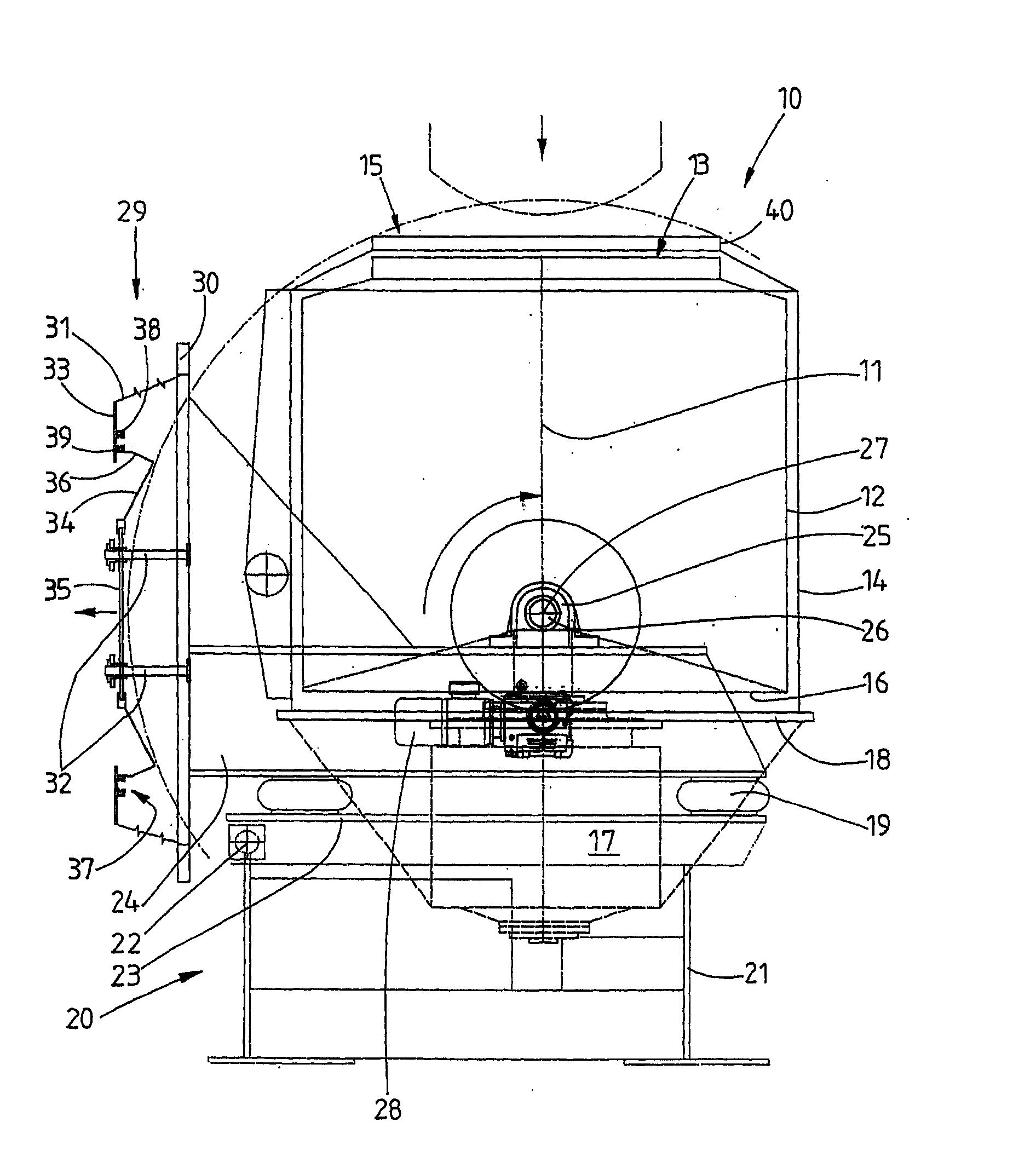

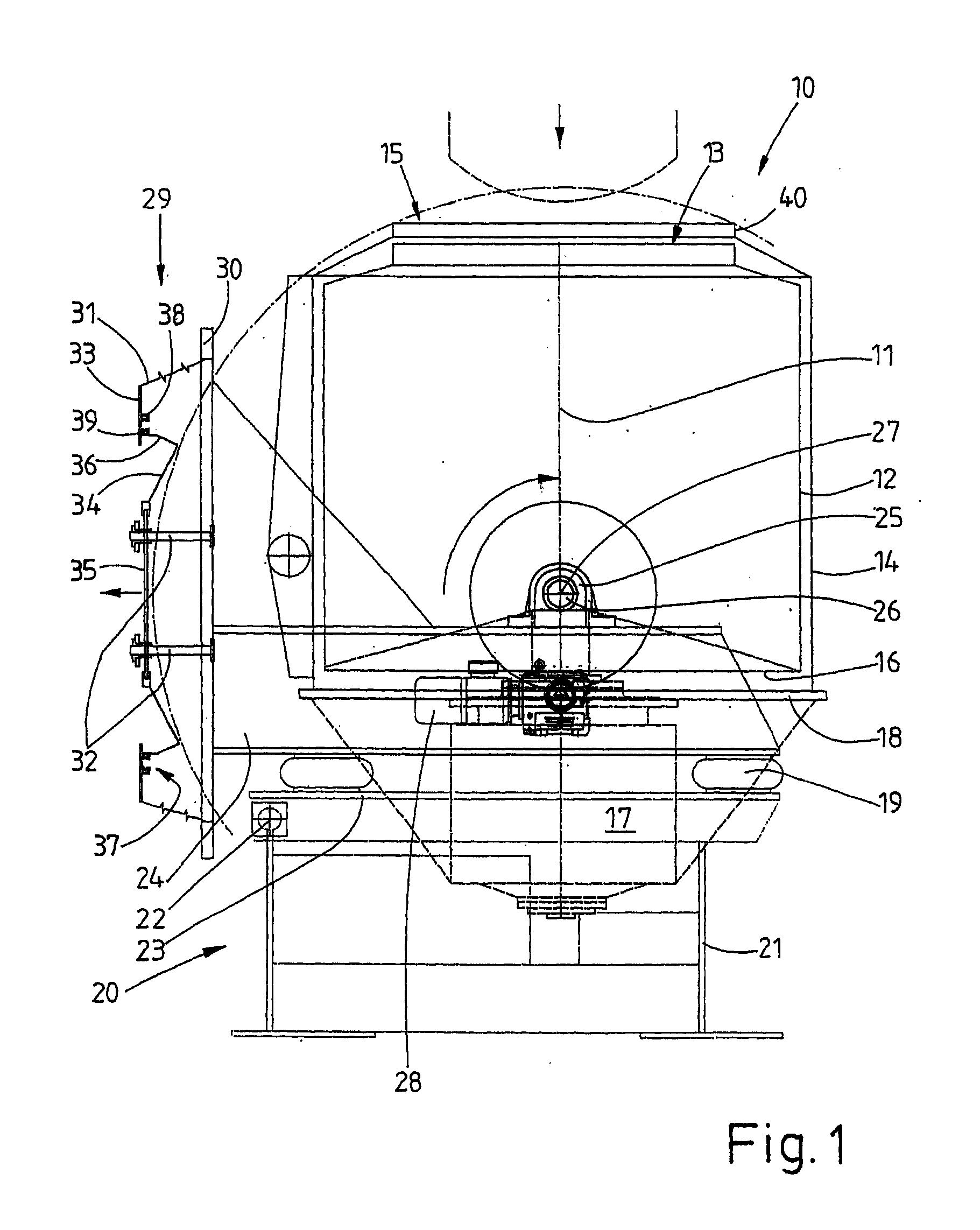

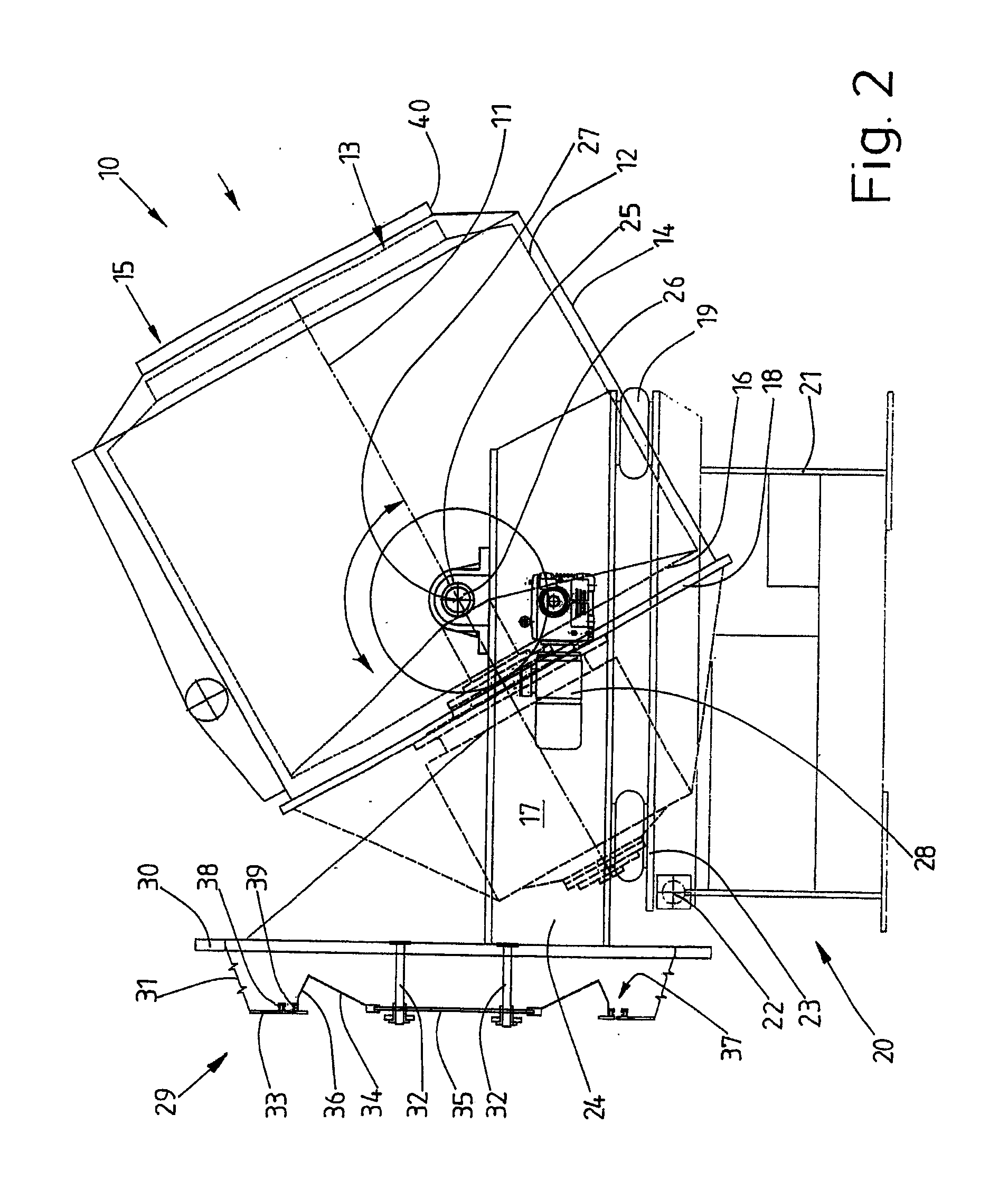

[0037] The device according to the first illustrative embodiment of the invention, shown in FIGS. 1 to 5, is a device designed as a washer-extractor 10 for standard commercial application. The washer-extractor 10 comprises an inner drum 12 which can be driven in rotation about a pivotable rotation axis 11. At one end face, the inner drum 12 has only a single opening 13 substantially across the whole surface. Moreover, the washer-extractor 10 comprises a water-tight drum housing 14 which surrounds the water-permeable inner drum 12 and which is stationary relative to the inner drum 12. Thus, in contrast to the inner drum 12, the drum housing 14 cannot be driven in rotation. On one end face, the drum housing 14 also has a single opening 15 across almost the whole surface. The opening 15 of the drum housing 14 is located in that end face of the drum housing 14 to which the opening of the inner drum 12 also points, such that the openings 13 and 15 are adjacent to one another and thus cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com