Woolen wool washing apparatus for chemical fiber production

a technology of chemical fiber and washing machine, which is applied in the field of woolen wool washing machine for chemical fiber production, can solve the problems of waste of energy, time-consuming and laborious processing, etc., and achieve the effects of improving the overall mechanical linkage of the device, high washing efficiency and improving the washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

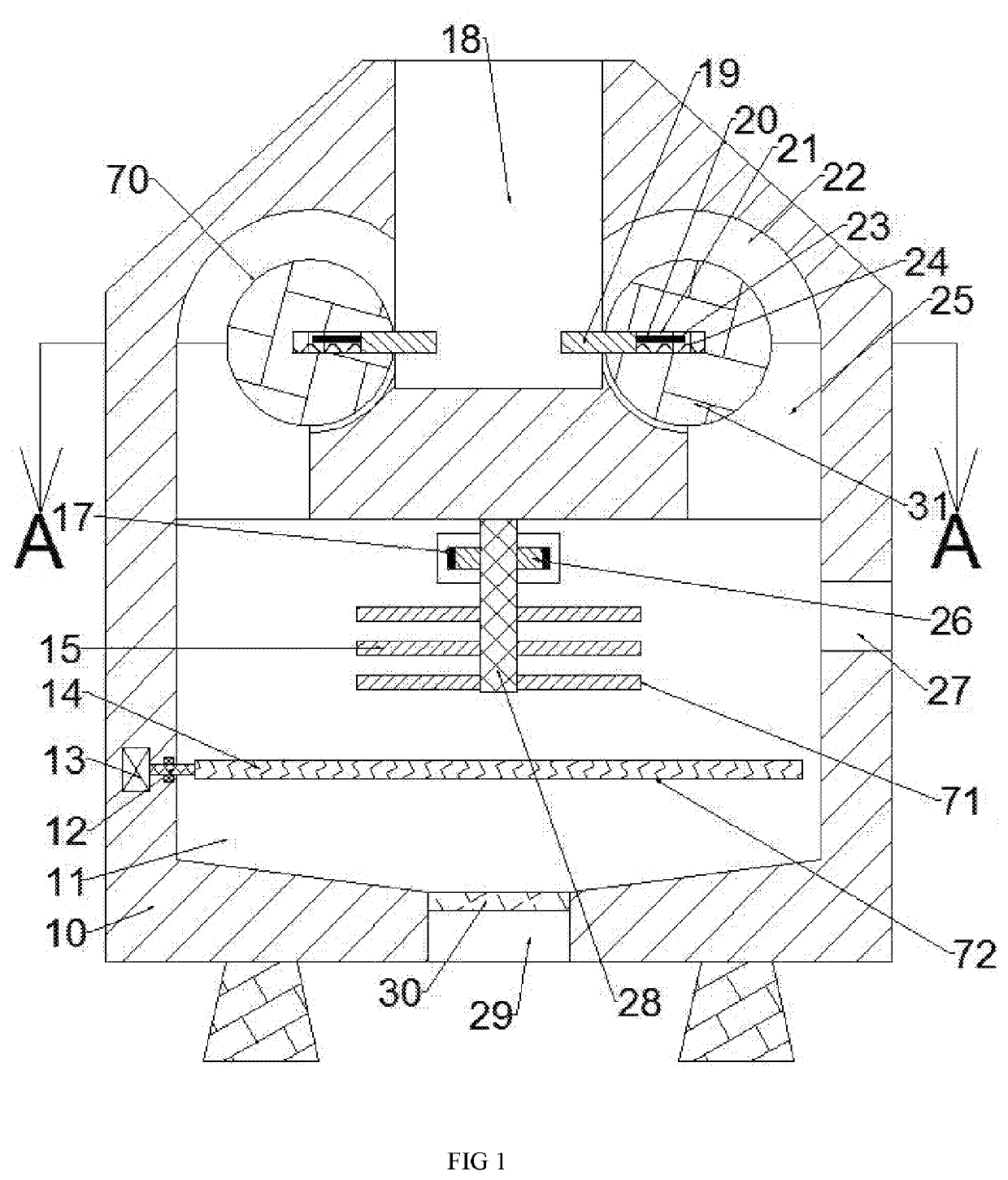

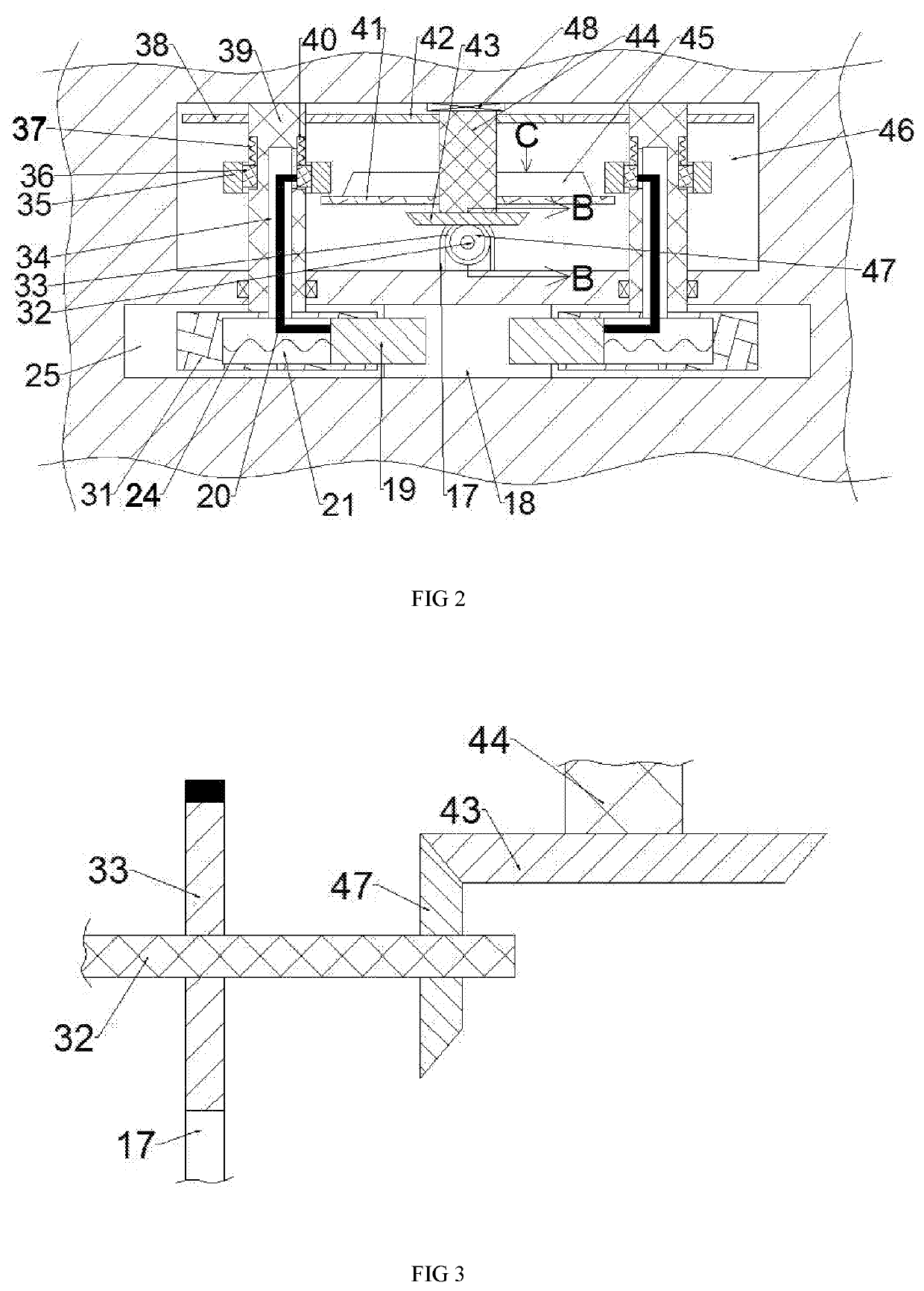

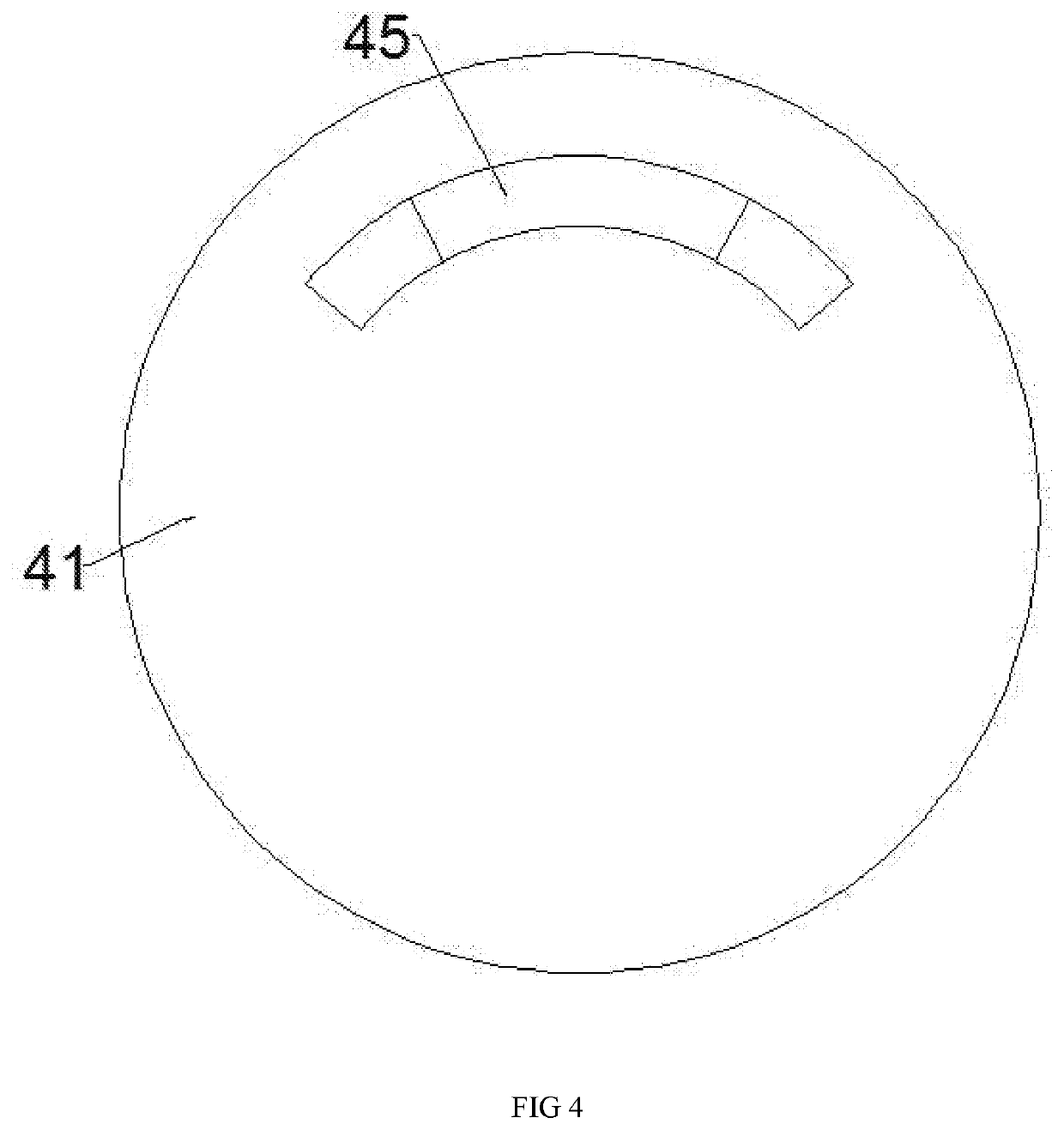

[0021]The present invention will be described in detail below with reference to FIGS. 1-4. For convenience of description, the orientation described below is defined as follows: the up-down, left-right, front-back direction described below is consistent with the up-down, left-right, front-back direction of the projection relationship of FIG. 1 itself.

[0022]A schematic diagram of the mechanical mechanism of a wool raw wool washing device for chemical fiber production, as shown in FIGS. 1-4, includes a washing machine 10, which is provided with a working chamber 46, and a front wall of the working chamber 46 is provided. There is a storage cavity 18 with an opening facing upward, and wool raw wool is installed in the storage cavity 18;

[0023]The working cavity 46 is provided with two dispersing mechanisms 70 symmetrically in the left and right. The dispersing mechanism 70 includes a connecting shaft 39 that is rotatably connected to the rear wall of the working cavity 46. A rotating wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotation | aaaaa | aaaaa |

| chemical | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com