Novel fiber mixing system

A new type of wool blower technology, used in textiles and papermaking, lubricating devices, fiber processing, etc., can solve the problems of insufficient oil supply, large labor consumption, influence and wool effect, and save labor consumption and labor consumption. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

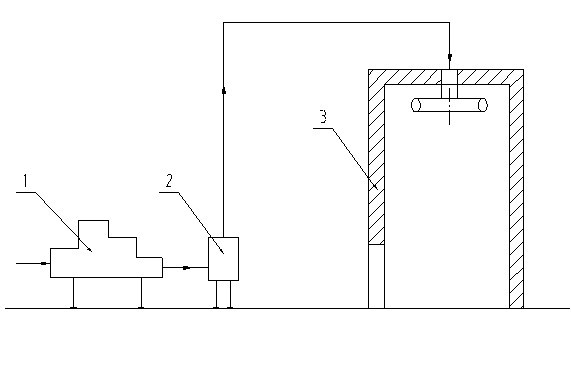

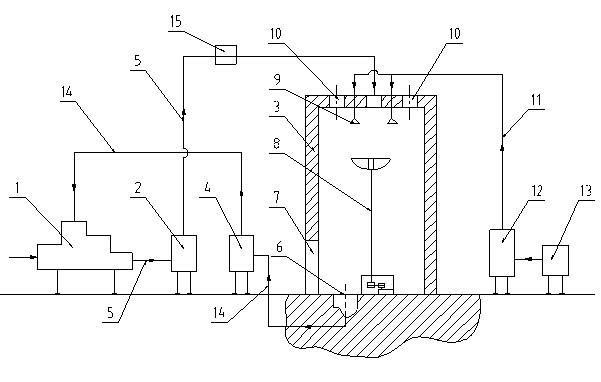

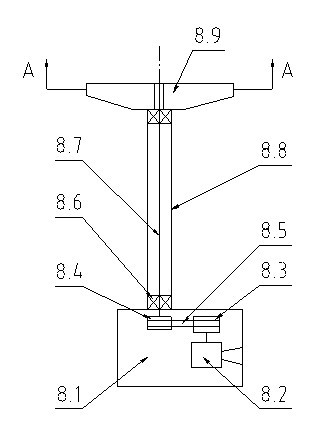

[0042] see figure 2 , the present invention relates to a novel blending system, which includes a blending machine 1, a hair blower 2 and a blending bin 3, the blending machine 1 and the blending fan 2 are located on the side of the blending bin 3, the blending The wool machine 1, the hair blower 2 and the hair bin 3 are connected successively through the hair delivery duct I5, and the hair suction fan 4 is arranged between the hair feeder 2 and the hair bin 3, and the hair bin 3 The bottom is provided with a ground suction port 6, and the ground suction port 6, the hair suction fan 4 and the wool machine 1 are sequentially connected through the hair delivery duct II14, and the fiber opener 8 is arranged in the wool warehouse 3, Above the fiber opener 8, a plurality of oiling agent nozzles 9 are arranged, and a hydraulic pump 12 and an oiling agent tank 13 are arranged on the other side of the wool bin 1, and the oiling agent tank 13, the hydraulic pump 12 and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com