Hygienic product packaging machine

A technology for sanitary products and packaging machines, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of large volume, high cost, difficult to use, etc., and achieve the effect of accurate number of pieces and sufficient opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

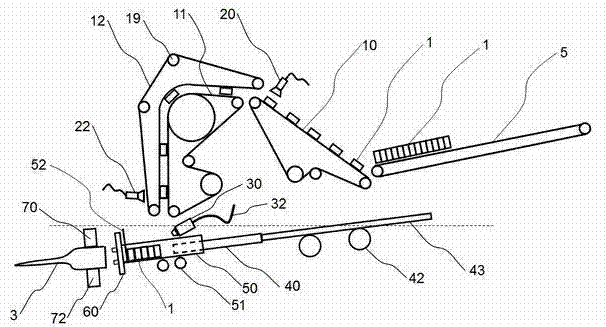

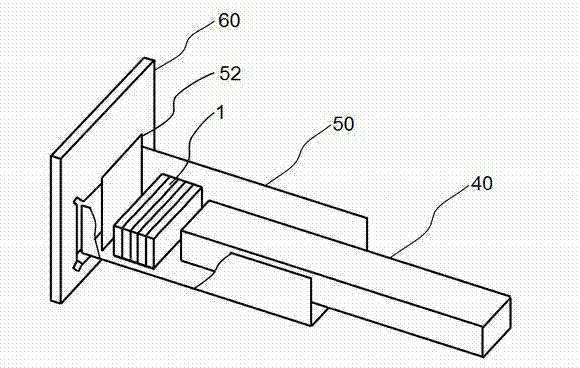

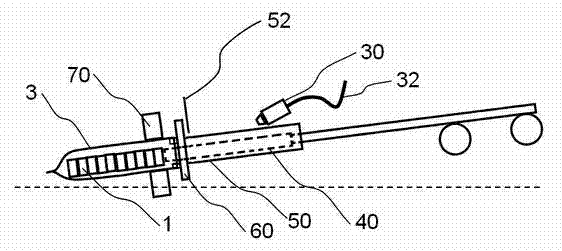

[0014] exist figure 1 Among them, the sanitary napkin single-piece 1 is automatically or manually put into the single-piece storage conveying tank, and a conveying belt 5 is arranged at the bottom of the single-piece storage conveying tank. In the storage chute, the individual sheets of sanitary napkins are held upright relative to the storage chute. The conveyor belt 5 drives the single piece of sanitary napkin 1 to move, and continuously delivers the single piece to the numbering module. The slice module includes at least one first-level slice sub-module and at least one second-level slice sub-module. The first series of sheet sub-modules include a transmission mechanism, a counting mechanism and other known auxiliary mechanisms. The transmission mechanism includes at least one mesh negative pressure belt 10 with a negative pressure structure, a belt tensioning mechanism, a belt driving mechanism, a belt supporting mechanism and a negative pressure generating device. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com