Ultrasonic washing and baking system for wool

A drying system and ultrasonic technology, applied in drying, dryer, animal loose fiber washing/scouring and other directions, can solve problems such as unclean cleaning, and achieve the effect of improving efficiency and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

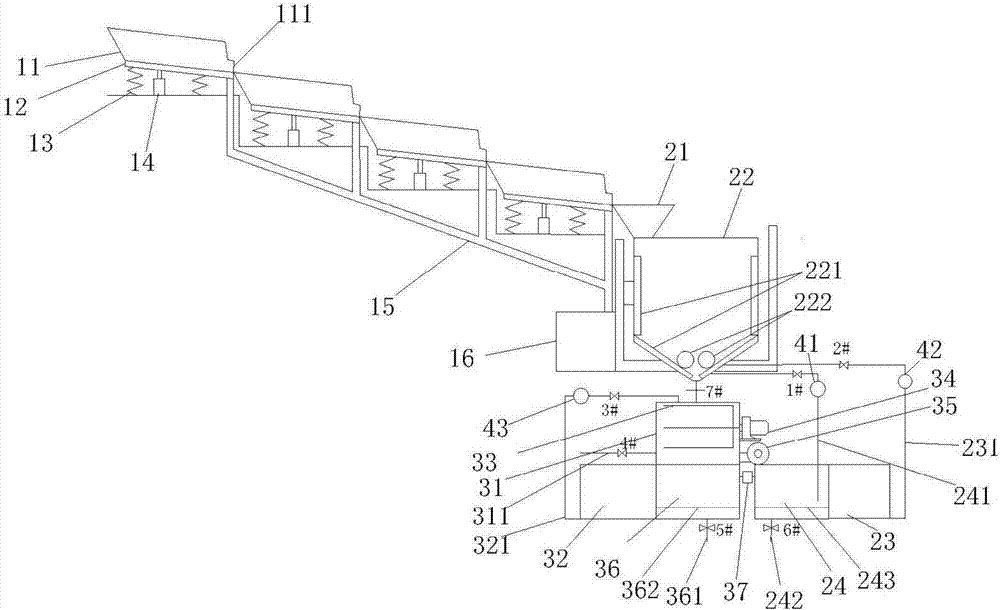

[0032] like figure 1 As shown, a wool ultrasonic cleaning and drying system includes a feeding device, a cleaning device and a rinsing and drying device. It is convenient for material transmission and can be transported from high to low at the same time. The vibration screening unit includes a material frame 11 arranged at an angle, a miscellaneous material layer 12 located at the bottom of the material frame 11, and a vibrating material layer 12 located at the bottom of the miscellaneous material layer. Spring 13 and vibrating motor 14, the material frame 11 is arranged obliquely and vibrates and transmits the effect of wool through the vibration of the vibrating motor 14 and the vibrating spring 13 at the same time. When wool is used, the screen can effectively screen out mud, sand, domestic impurities and other miscellaneous materials. One end of the material frame 11 is provided with a discharge port 111, and the end of the miscellaneous material layer 12 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com