Device and method for improving cleanness and bulkiness of water-washed down

A technology of bulkiness and cleanliness, which is applied in the field of devices for improving the cleanliness and bulkiness of washed down, can solve the problems affecting the bulkiness and cleanliness of washed down, reduce product cost, deteriorate the quality of washed down, etc., so as to eliminate the smell of duck feathers. , reduce costs, eliminate the effect of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

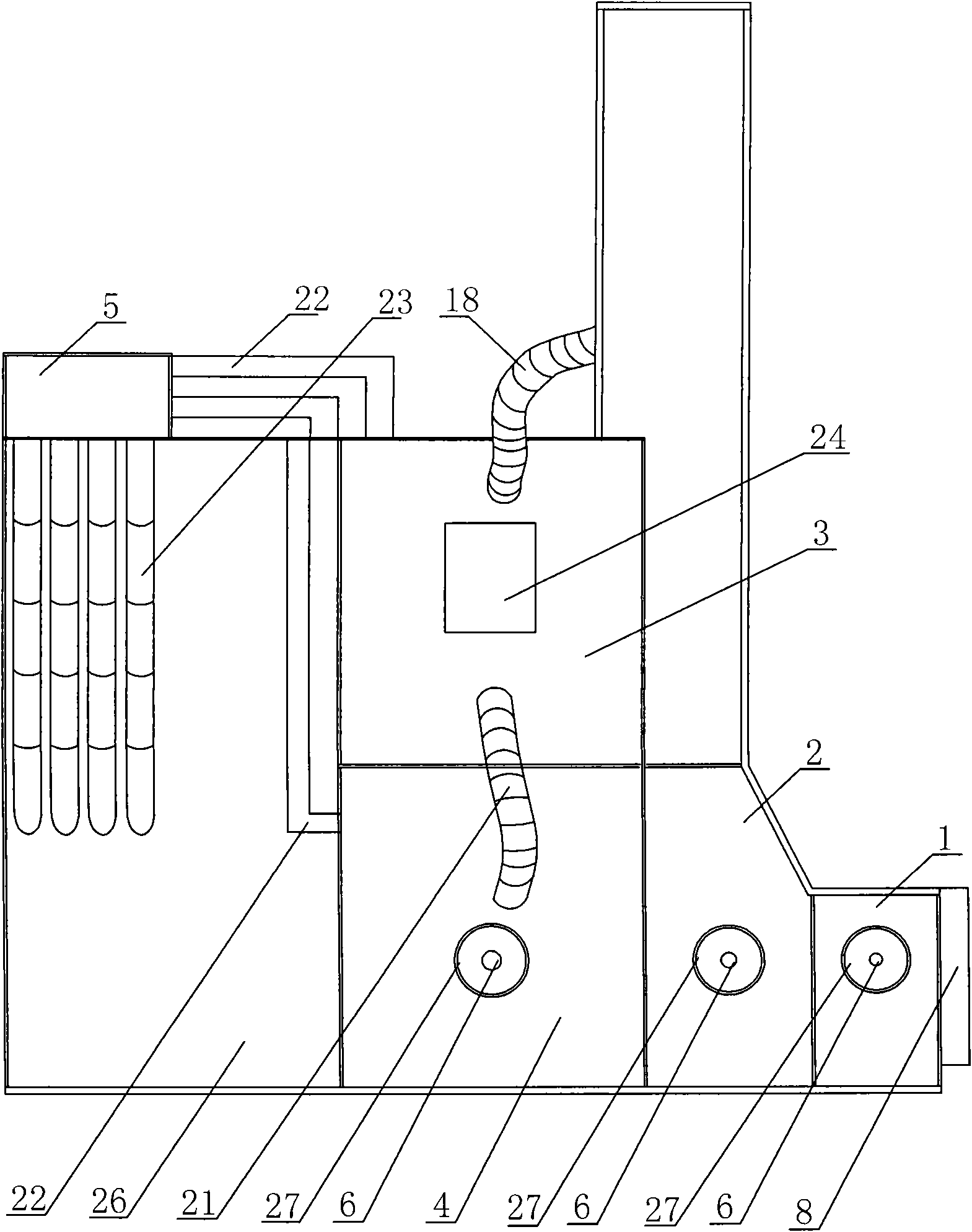

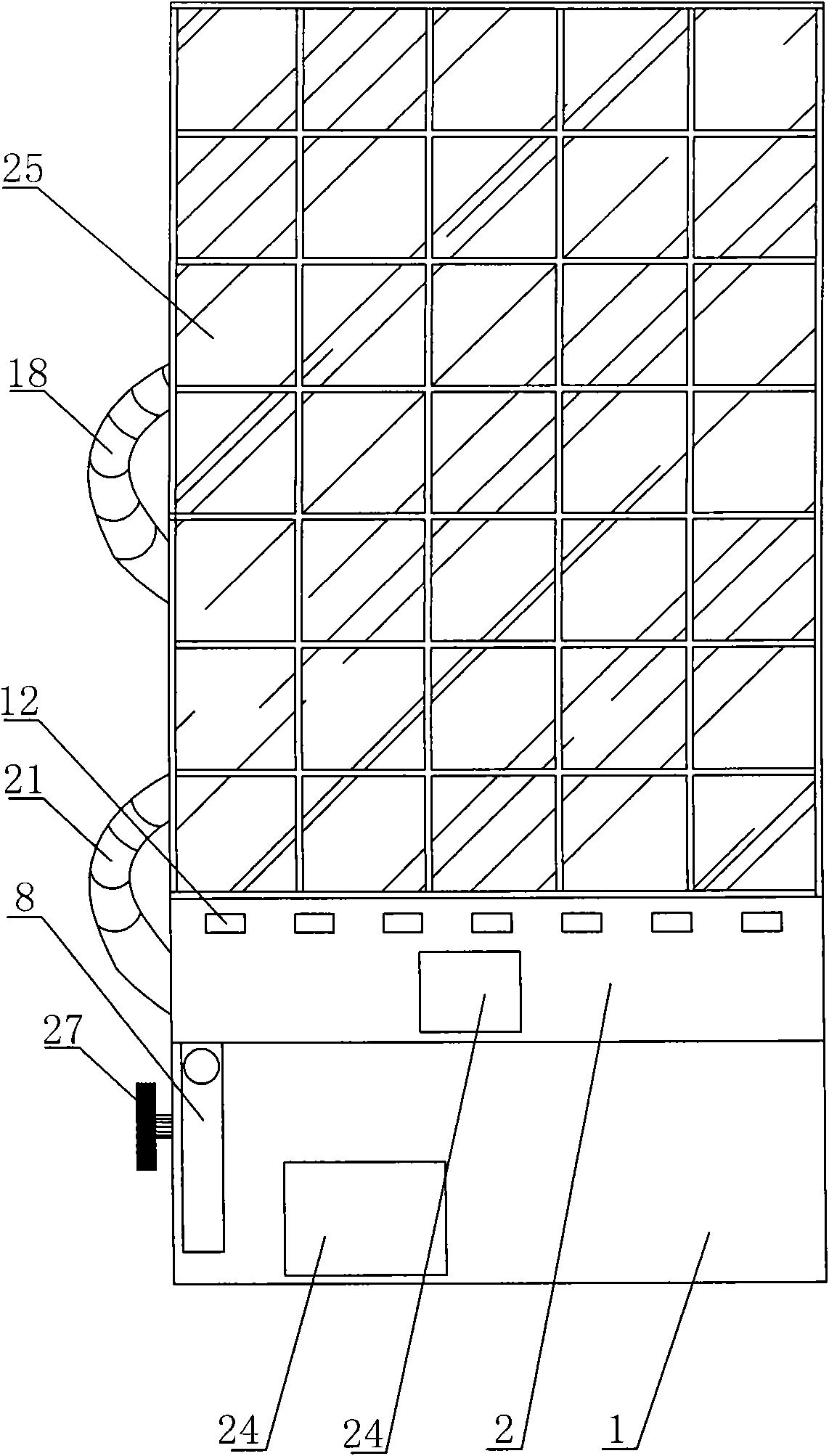

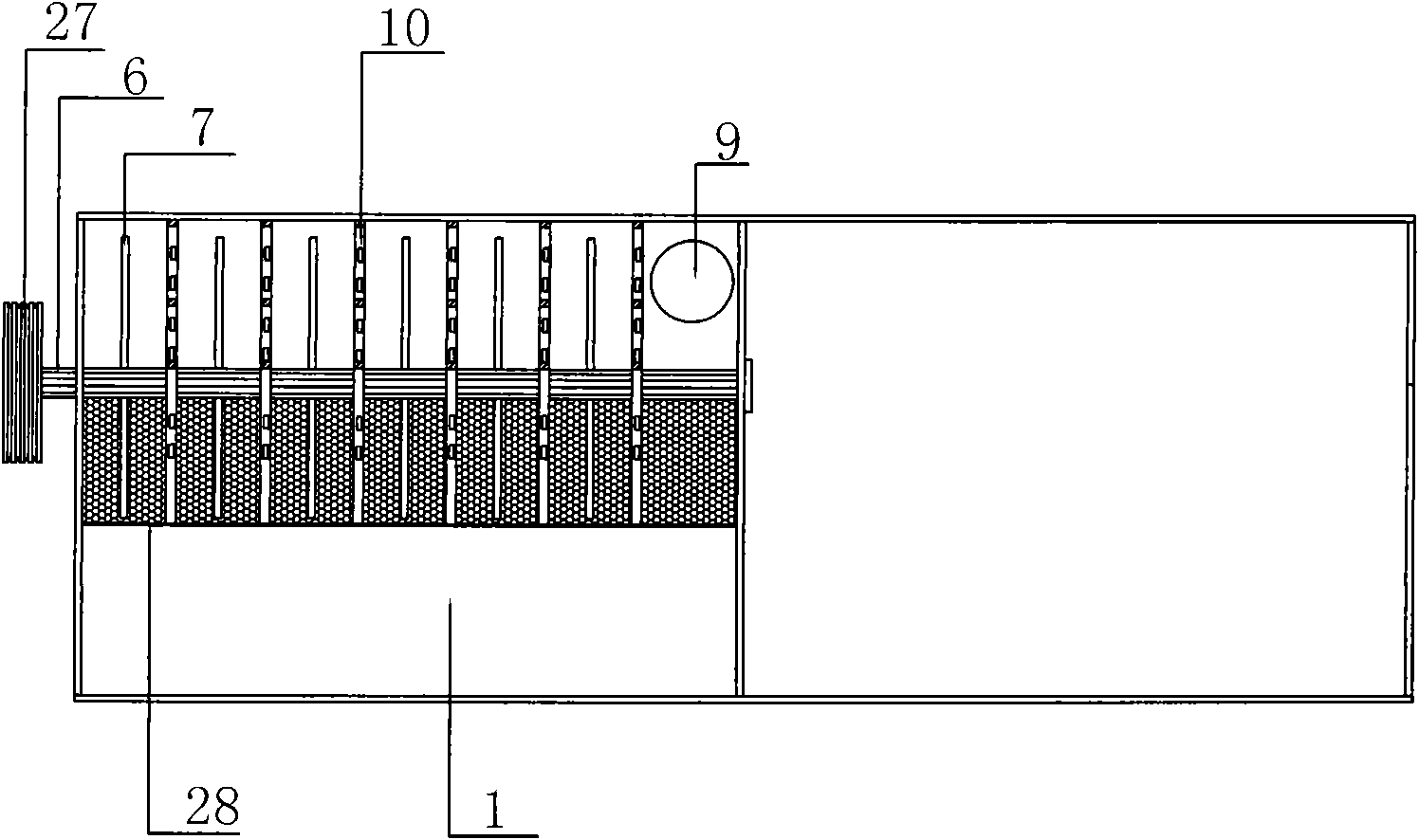

[0027] Such as figure 1 , 2 As shown, a device for improving the cleanliness and bulkiness of washed eider down includes iron removal box 1, neck hair removal box 2, dust removal box 3, down fluffy box 4 and exhaust fan 5, and described iron removal box 1, removal of iron Neck hair case 2, dedusting case 3 and down fluffy case 4 are respectively provided with detection door 24, to facilitate observing the situation in the case. One end face of the described neck hair removal box 2 adopts the structure of glass partition window 25, and the height of the neck hair removal box 2 is 10m, and the neck hair removal box is designed with such a high height, which is the best for the neck hair and down. The separation reserves enough space to improve the separation effect of neck hair and down. The dust removal box 3 and the feather fluffy box 4 are respectively connected with 18 exhaust pipes 22 , the other end of each exhaust pipe 22 is connected with a dust bag 23 , and the exhaus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com