Method for producing, processing and post-processing down filler

A filling material and down technology, which is applied in the processing of textile materials, spray/jet textile material processing, fiber processing, etc., can solve the problems of poor fluffy effect of down products, easy damping of down filling materials, and reduced thermal insulation performance. Inhibits growth and reproduction, is easy to care for, and enhances warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

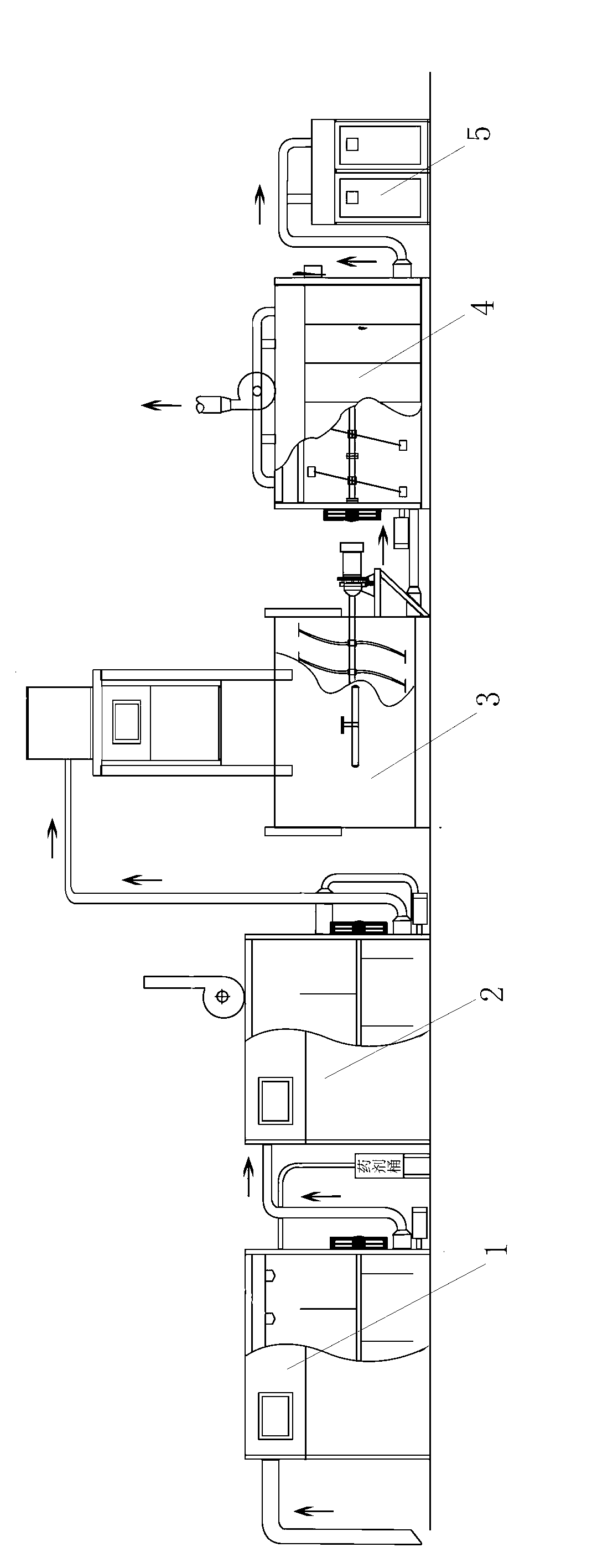

[0027] The post-processing method of production and processing of down filling materials, such as figure 1 shown, including the following steps:

[0028] Step a. Spraying: select 60kg of washed finished eider down produced by common production process for reprocessing, pump the above-mentioned finished eider down into the spraying machine with an exhaust fan, and spray it at a rate of 0.5-1kg / cm 2 The air pressure pumps the treatment liquid from the volume barrel to the nozzle of the sprayer, and the nozzle is 5-6 kg / cm 2 The air pressure sprays the treatment liquid evenly in the sprayer in the form of mist, and stirs at the same time. The spraying lasts for 20-40 minutes, and the stirring continues for 5-10 minutes after spraying;

[0029] Step b. Adhesion and fixation: pump the sprayed damp down into the fixed compartment with an exhaust fan, blow it with hot air at 25-35°C for 15-30 minutes, and stir while blowing;

[0030] Step c. Drying: the air-dried down in the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com