Down feather dedusting device for textiles

A dust removal device and down technology, which is applied in the textile field, can solve the problems of down being mixed with dust, affecting the quality of down, and unsatisfactory cleaning effect, etc., and achieve the effect of improving quality, good promotion and utilization value, and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

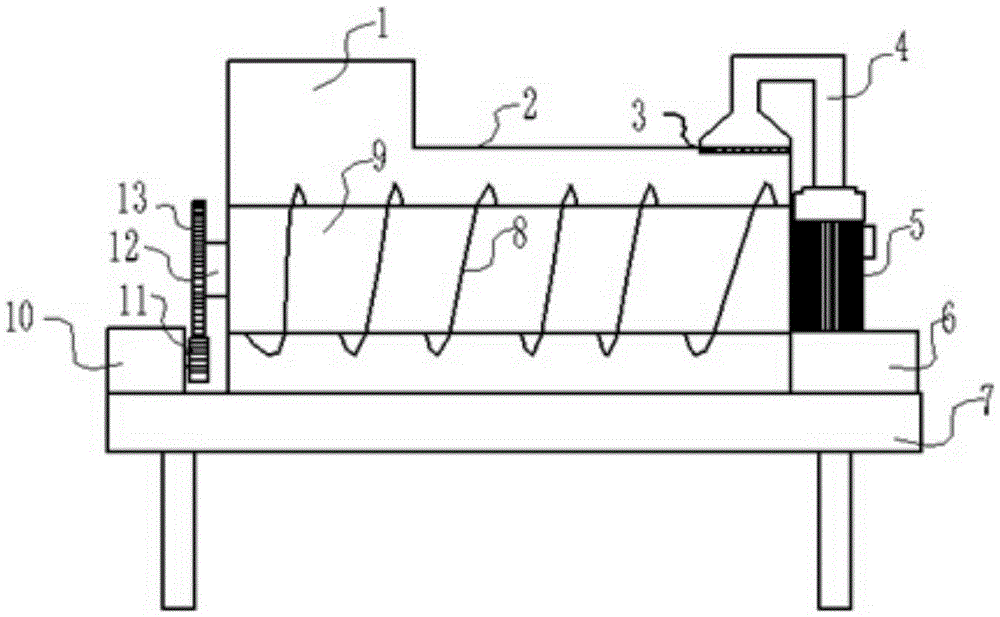

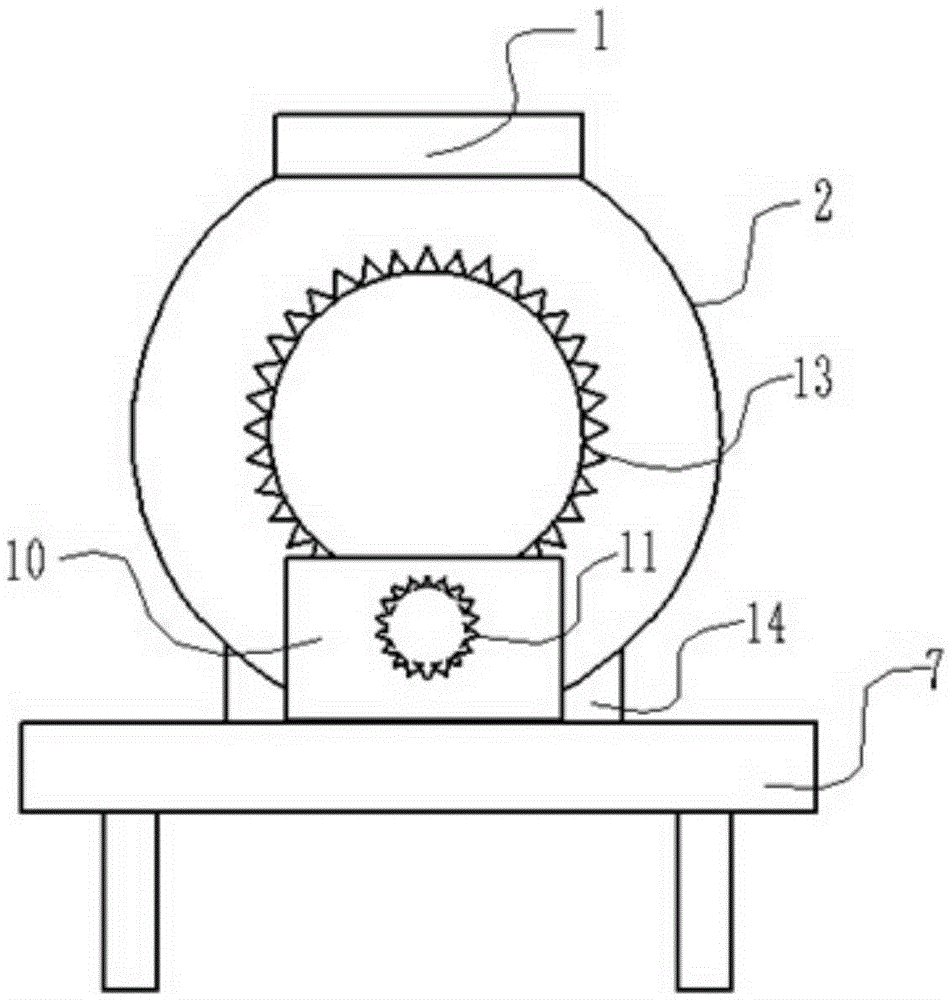

[0018] Such as figure 1 , figure 2 As shown, the down and dust removal device for textiles has a structure comprising a box body 2, on which a feed inlet 1 is arranged, and a roller 9 is arranged horizontally in the box below the feed inlet 1, and the two ends of the roller pass through the main drive The shaft is connected to the box in rotation; the outer surface of the drum 9 is provided with stirring blades 8, and the drum 9 and the stirring blades 8 are connected by welding, so the stirring blades fully stir the down and down inside the device to make the down and dust completely Separated and ready for the next step of dust removal.

[0019] In the above example, specifically, one side of the box 2 is provided with a motor 10, the motor is connected through the motor shaft, the second transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com