Efficient down feather iron removal and impurity removal device

A high-efficiency, down-and-down technology, which is applied in the direction of fiber mechanical cleaning, animal fiber cleaning machines, textiles and papermaking, etc., can solve the problems that iron filings cannot be completely removed, the height of the outer cylinder is limited, and the effect is not good. Thorough, improve production efficiency, easy to clean the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

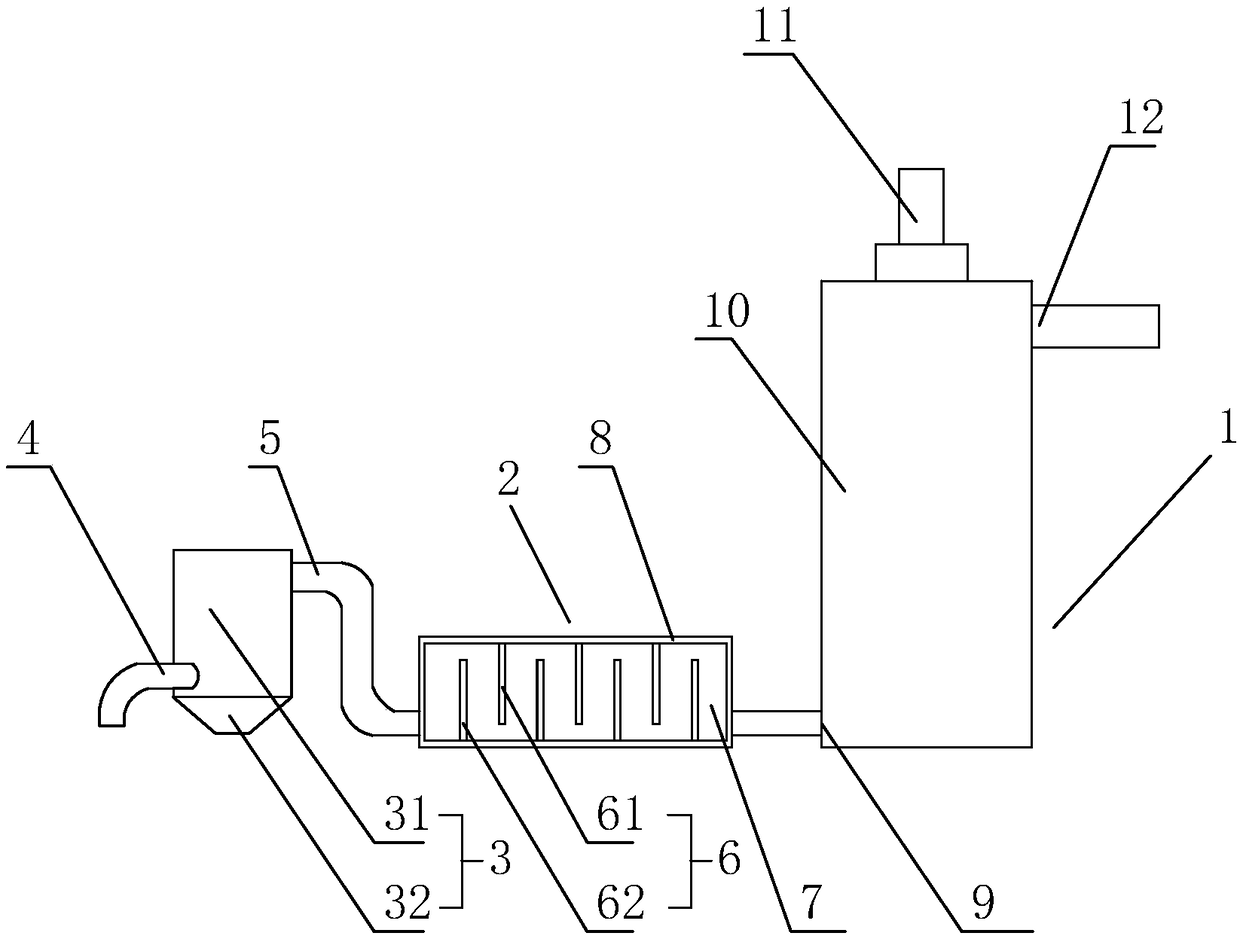

[0017] Reference Figure 1 to Figure 4 The embodiment of the high-efficiency iron and impurities removing device for down of the present invention will be further described.

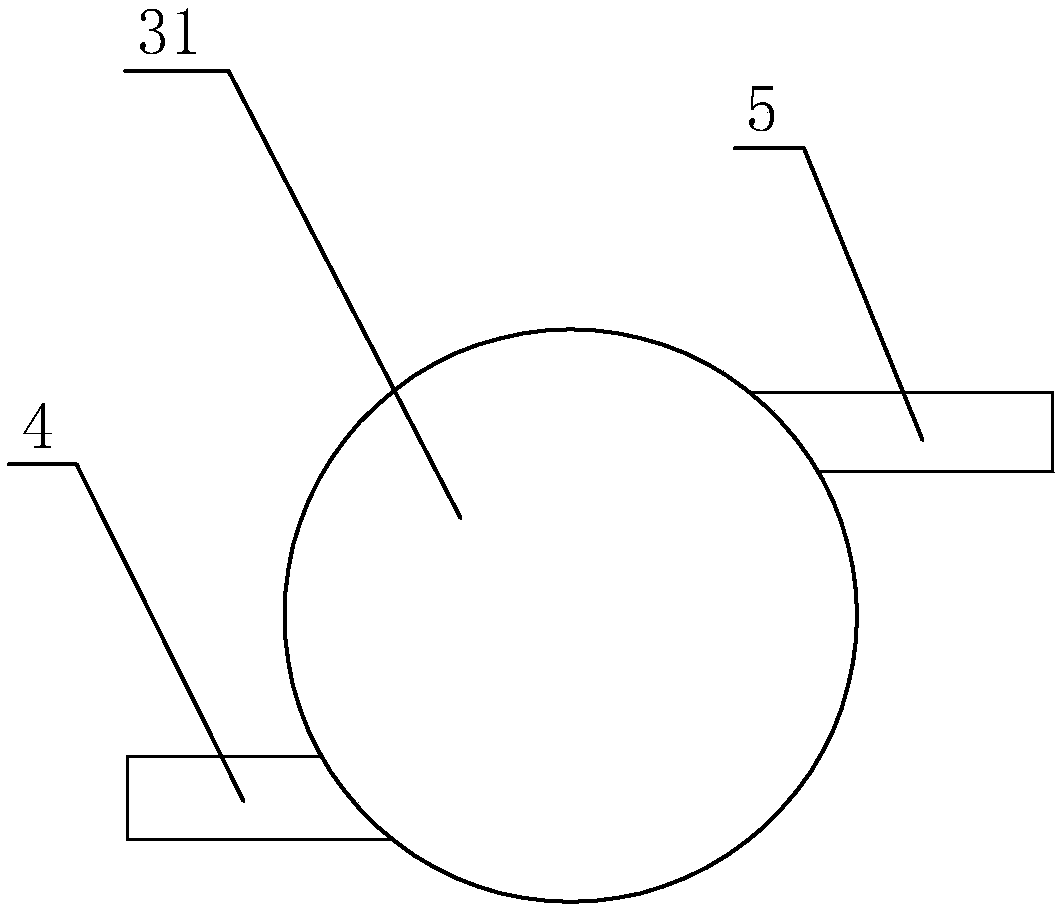

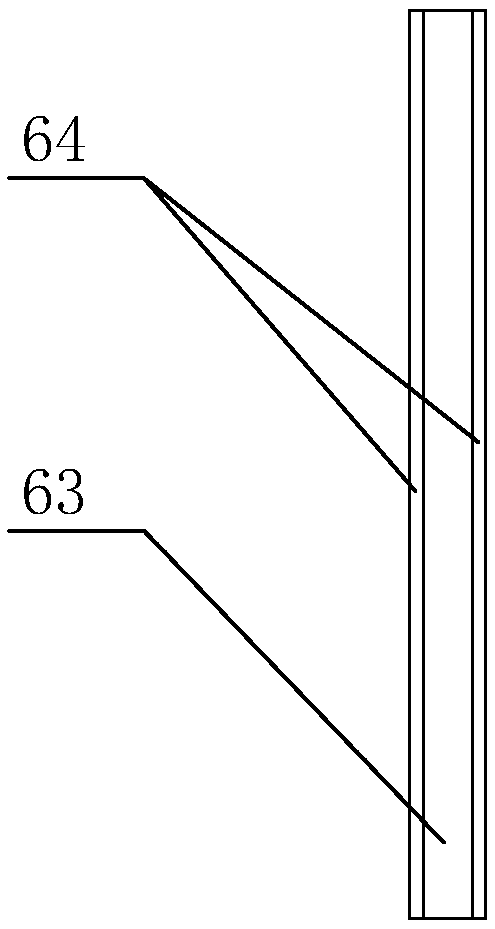

[0018] An efficient de-ironing and impurity removal device for down, comprising a vertical iron-removing drum 1 which includes an outer drum 10 in which a rotating shaft 13, a stirring rod 14, a magnet holder, a magnet and a drive are arranged The motor 11 is provided with a feed port 9 under the outer cylinder 10 and a discharge port 12 at the top. A horizontal iron removal box 2 is connected in front of the feed port 9 and the horizontal iron removal box 2 includes a box body 8. A number of magnetic plates 6 are arranged in the box body 8. The magnetic plate 6 includes an upper magnetic plate 61 and a lower magnetic plate 62. The upper magnetic plates 61 and the lower magnetic plates 62 are alternately arranged in turn. 61 and the lower magnetic plate 62 form a broken line air duct 7 in the box 8.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com