Oiling method and oiling device of wool lubricant during slivering process of cashmere

A technology of refueling device and oil injection device, which is used in lubrication devices, textiles and papermaking, fiber processing, etc., can solve the problems of pollution of conveying pipelines, adhesion of conveying belts, excessive oily hair or fluff, etc., to increase economic benefits and installation location. Reasonable and penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

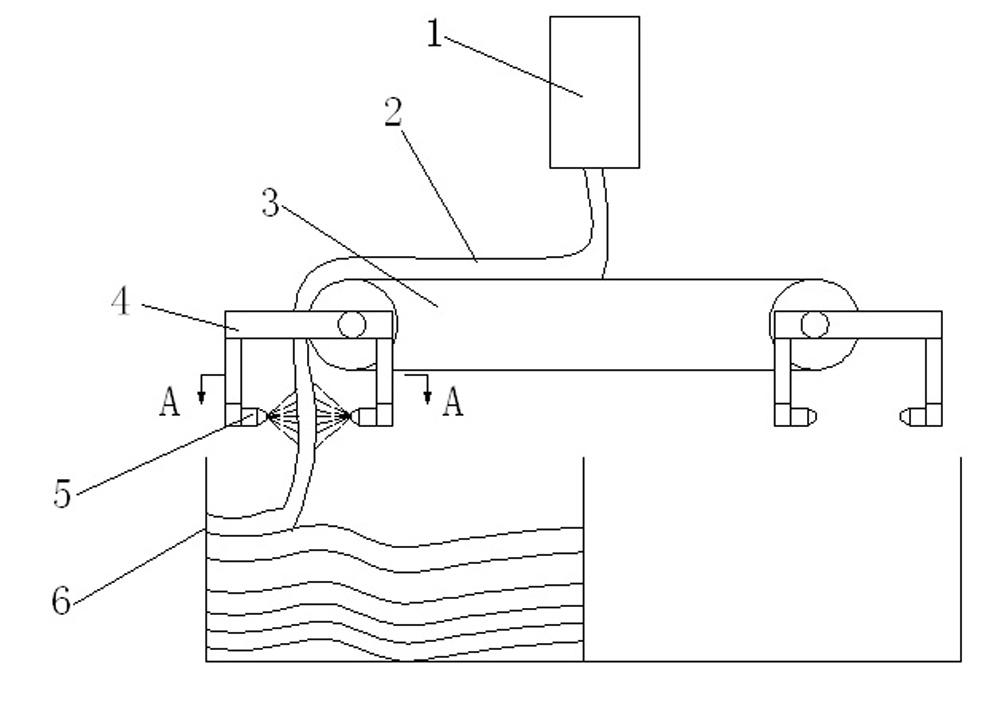

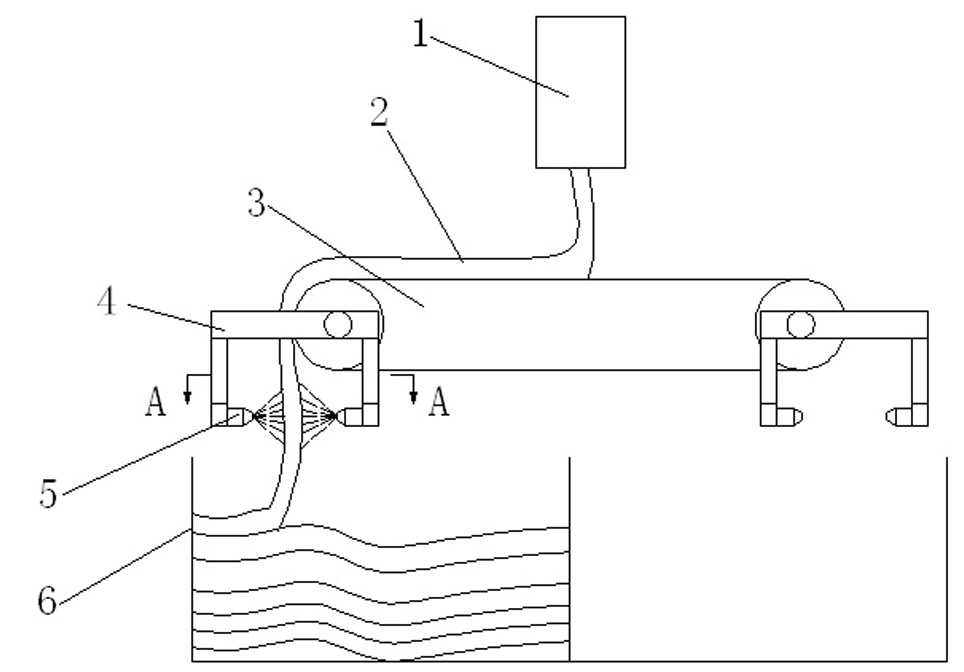

[0013] The structure of the present invention will be described below in conjunction with the accompanying drawings.

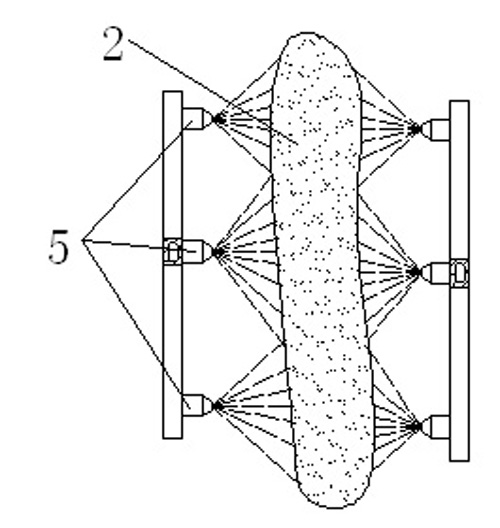

[0014] as attached figure 1 , 2 As shown, a conveyer belt 3 that can move left and right is installed under the velvet device 1, and supports 4 are fixedly installed at both ends of the conveyer belt, and the 6 on the left side of the conveyer belt and the crude oil nozzle 5 are divided into 2 groups. It is fixedly installed on the bracket, and the level of the crude oil spray head is lower than the level of the conveyor belt. The cashmere raw material 2 falling from the condenser falls on the conveyor belt. When the conveyor belt rotates counterclockwise and moves left and right, the cashmere raw material falls from the left end of the conveyor belt and is evenly stacked in the wool bin 6 on the left. . During the falling process, the cashmere raw material passes between the two groups of hair oil nozzles arranged oppositely at the left end, at this time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com