Thread trimming and presser foot lifting mechanism of sewing machine and sewing machine

A thread-cutting mechanism and presser-lifting technology are applied to thread-cutting mechanism, cloth pressing mechanism, sewing machine components and other directions in sewing machines, which can solve problems such as reducing competitiveness, increasing product production costs, affecting the service life of components, etc. Simple operation, simple post-modification, good heat dissipation protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

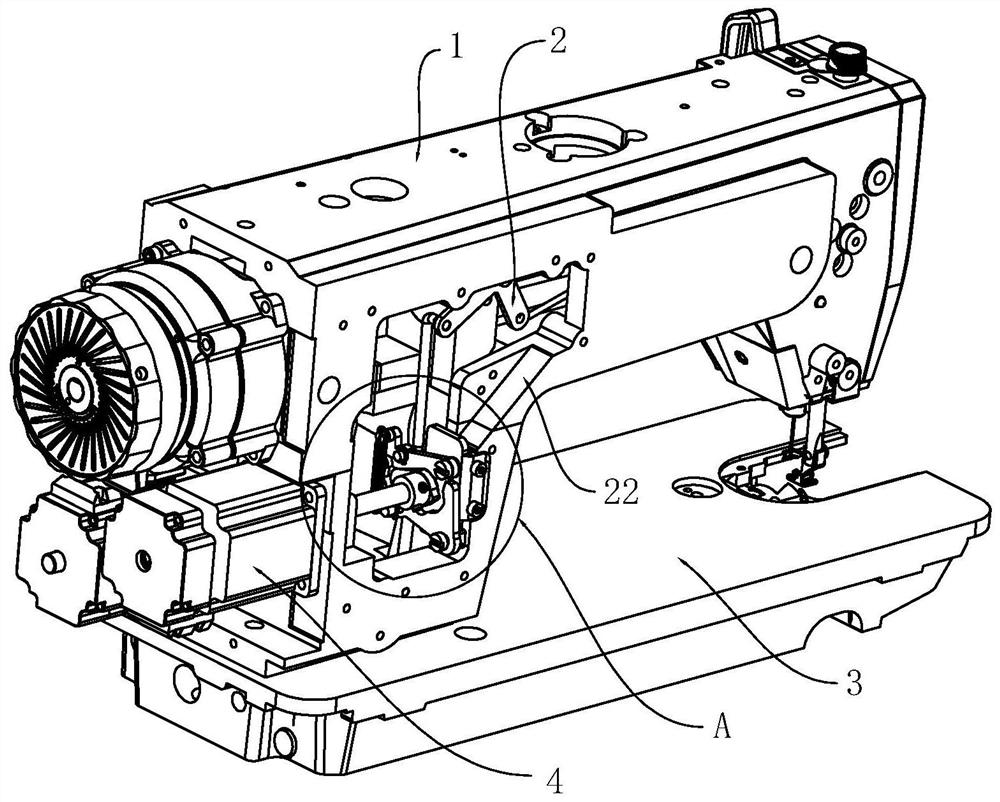

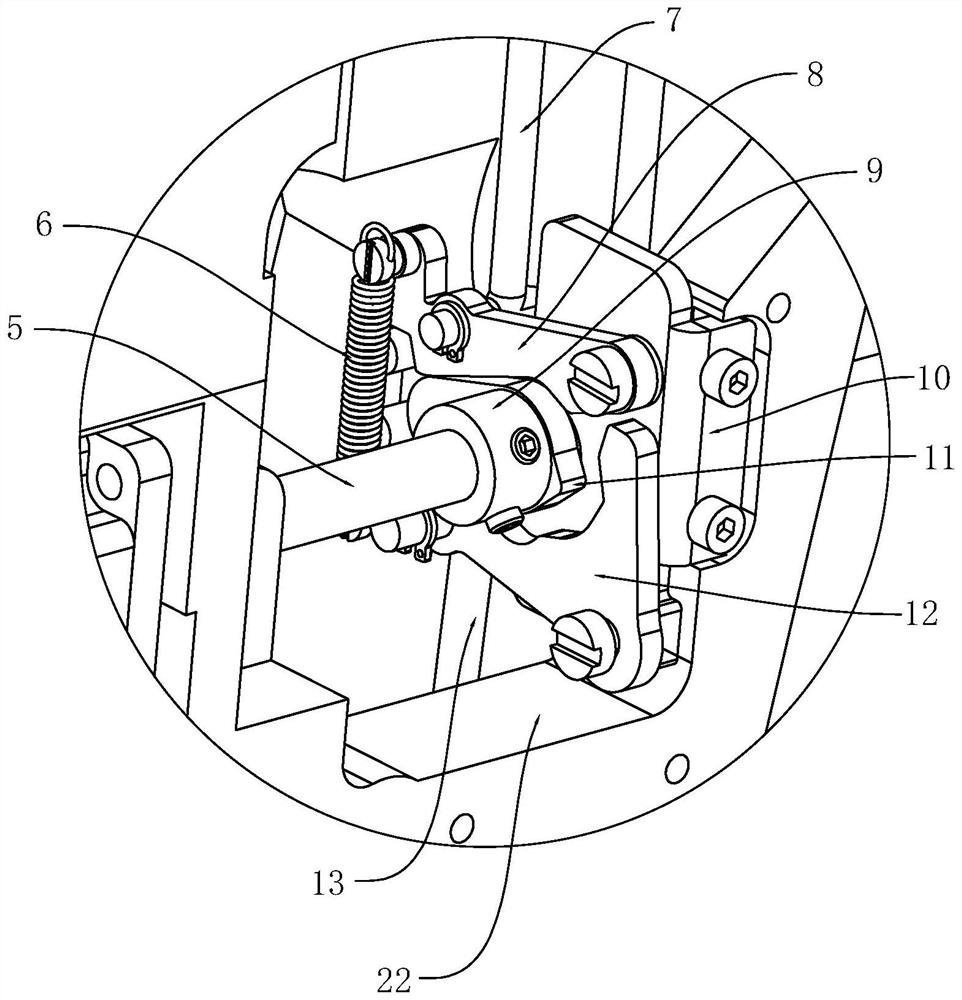

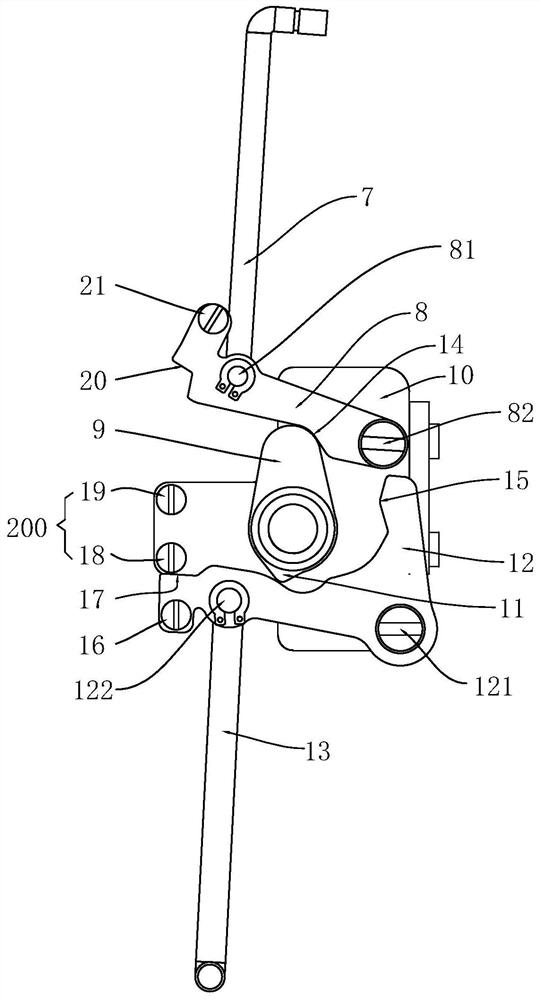

[0036] Embodiment one: if Figure 1-5 As shown, a thread trimming and presser foot lifting mechanism of a sewing machine is provided with a presser foot lifting mechanism 2 at the top of the frame 1, a thread trimming mechanism 32 is provided at the bottom of the frame 1, and a thread trimmer 32 is provided at the middle of the side of the frame The drive motor 4, the motor shaft 5 of the drive motor stretches into the frame 1 and drives the thread trimming mechanism 32 and the presser foot lifting mechanism 2 respectively;

[0037] The motor shaft 5 is provided with a cam 9, the upper side of the cam 9 is provided with a presser foot lifting swing bar 8, and the lower side of the cam 9 is provided with a thread trimmer swing bar 12; Foot fork 8 or thread trimming fork 12, and then respectively drive presser foot lifting mechanism 2 to realize lifting presser foot, or, and then drive thread trimming mechanism 32 to realize automatic thread trimming;

[0038] One end of the pr...

Embodiment 2

[0064] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that: the inner wall of the installation window described in this embodiment refers to figure 2 outside the position of the installation window shown; of course, it can also be installed on the wall of the inner cavity of the rack 1 by changing the shape of the bracket, so that the entire structure can be located inside the installation window, thereby further reducing the impact on the current situation. Due to structural impacts, the existing rear window cover can completely cover the installation window 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com