Preparation method of chitin antibacterial fiber yarn and application in householde textile

An antibacterial fiber and chitin technology, which is applied in fiber treatment, textiles, papermaking, yarn, etc., can solve the problems of fiber nets falling easily, low fiber crimps, and small fiber cohesion, and achieve excellent fiber transfer quality and controllable transfer Good performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

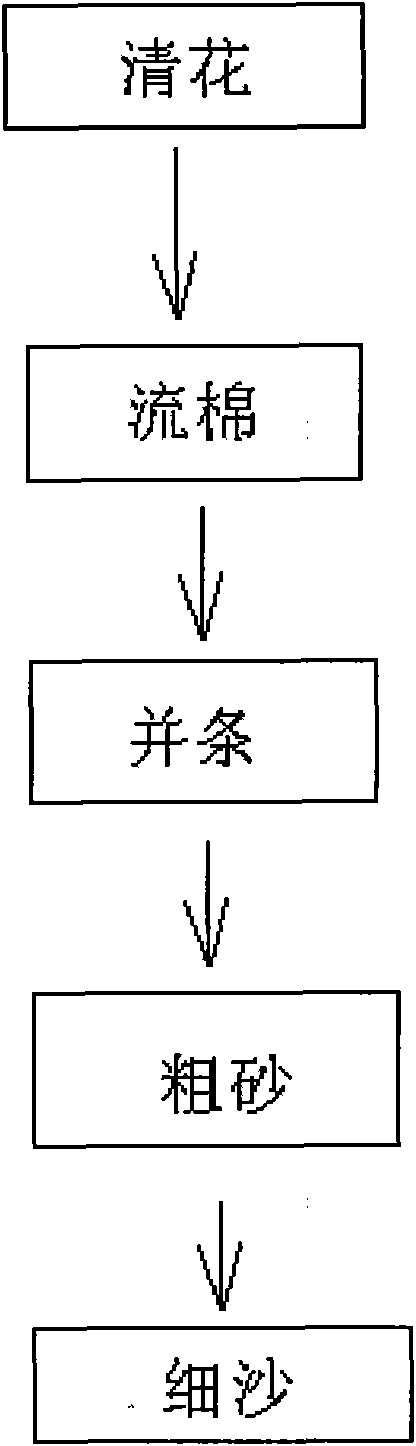

[0014] The invention relates to a preparation method of chitin antibacterial fiber yarn, which comprises the steps of blowing, spinning, drawing, coarse sand and fine sand.

[0015] Among them, (1) cleaning process

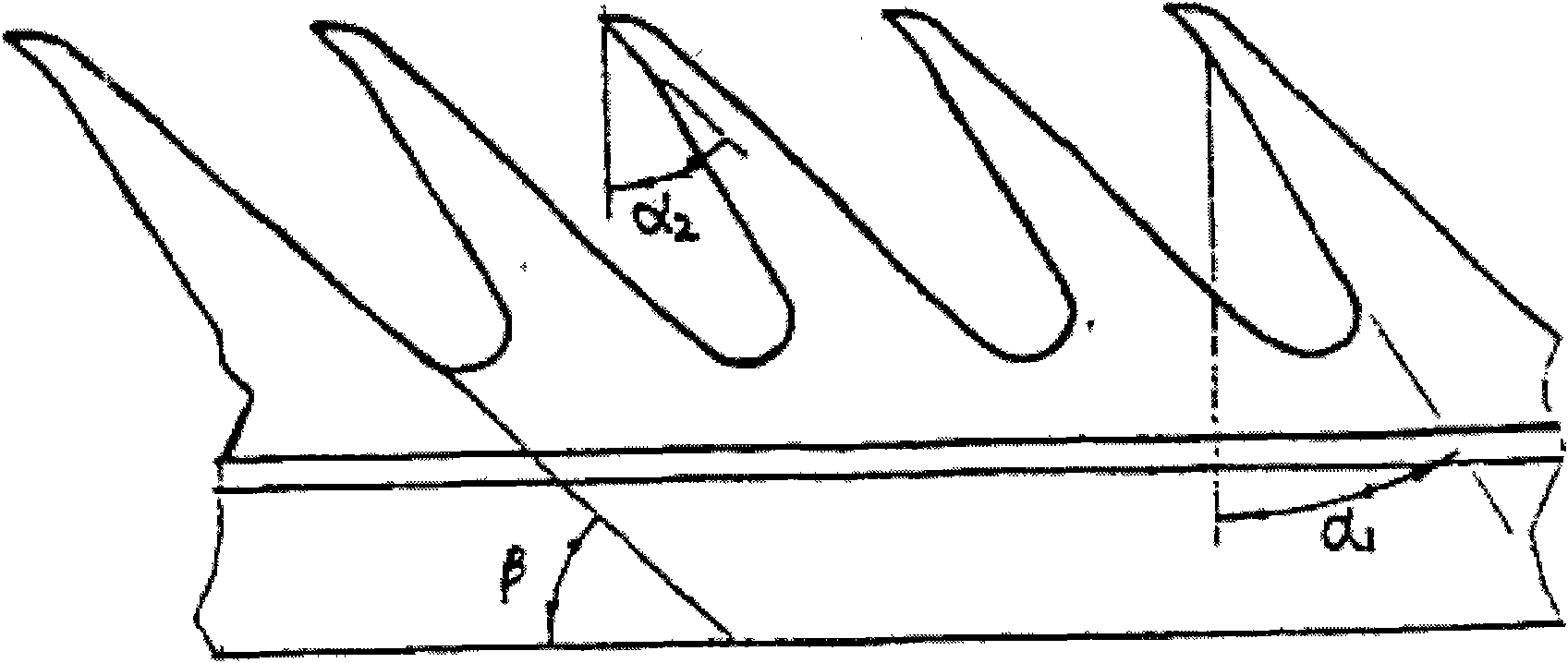

[0016] In the cleaning process, it is advisable to grasp more frequently and less grasp, more loose and less beating, more collecting and less shedding, more mixing and less tumbling, using comb needle beaters, and implementing the process principles of low speed, large gauge and anti-adhesion. The distance between the beater and the cotton feeding roller should be relatively large to reduce fiber damage and the generation of short fibers, and anti-sticking measures should be taken, such as using anti-sticking rollers, increasing the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com