Production method for water-repellent non-woven fabric

A technology of non-woven fabrics and water-repellent oil agents, which is applied in the fields of non-woven fabrics, textiles, papermaking, and medical science. Leakage, good water repellency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

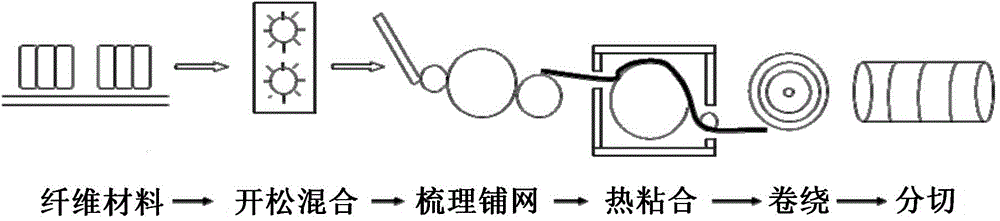

Image

Examples

Embodiment 1

[0022] Embodiment 1: a kind of nonwoven fabric, comprises fiber net, sheath-core structure, and described sheath-core structure is made of PET / PE composite fiber, and wherein PET layer is mutually welded together to form bridging structure by molten PE, and PET layer is curly shape. The denier of the composite fiber in the nonwoven fabric ranges in thickness from 1 to 6D, and the length ranges from 30 to 60 mm. The thickness range of non-woven fabric is 0.5-2.0mm, and the weight is 20-30g / m 2 .

[0023] Preparation of PET / PE sides with skin-core structure

[0024] Preparation steps: After fully opening the raw materials, removing impurities and mixing them, they are carded into a fiber web by a carding machine. There are too many fibers in the fiber web longitudinally, and the fiber web is sent to the hot air device by using a conveyor belt. The temperature is set at 140°C and the wind pressure is 50Hz. When the fiber web passes through the hot blast furnace, it encounters ...

Embodiment 2

[0025] Embodiment 2: A kind of nonwoven fabric, comprises fiber net, sheath-core structure, and described sheath-core structure is made of PP / PE composite fiber, and wherein PP layer is mutually welded together to form bridging structure by molten PE, and PP layer is curly shape. The denier of the composite fiber in the nonwoven fabric ranges in thickness from 1 to 6D, and the length ranges from 30 to 60 mm. The thickness range of non-woven fabric is 0.5-2.0mm, and the weight is 20-30g / m 2 .

[0026] Preparation of PP / PE side with skin-core structure

[0027] Preparation steps: After the raw materials are fully opened and mixed, they are carded into a fiber web by a carding machine. The fibers in the fiber web are arranged in a longitudinal direction, and the fiber web is sent to the hot air device-flat mesh hot air furnace by a conveyor belt, and the temperature is set. Set at 135°C, wind pressure 30Hz, during the process of passing through the hot blast furnace, the fiber...

Embodiment 3

[0028] Embodiment 3: a kind of nonwoven fabric, comprises fiber web, sheath-core structure, and described sheath-core structure is made of PET / PE composite fiber, and wherein PET layer is mutually welded together to form bridging structure by molten PE, and PET layer is curly shape. The composite fibers in the non-woven fabric have a thickness range of 6-10D and a length range of 10-30 mm. The thickness of the nonwoven fabric ranges from 0.1 to 0.5mm, and the weight is 10 to 20g / m 2 .

[0029] Preparation of PP / PE side with skin-core structure

[0030] Preparation steps: After fully opening the raw materials, removing impurities and mixing them, they are carded into a fiber web by a carding machine. There are too many fibers in the fiber web longitudinally, and the fiber web is sent to the hot air device by using a conveyor belt. The temperature is set at 140°C and the wind pressure is 20Hz. When the fiber web passes through the hot blast furnace, it encounters hot air with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com