Water-based elastic rubber paint and preparation method thereof

A kind of hand-feeling paint and elastic technology, which is applied in the field of coatings, can solve the problems of poor weather resistance, etc., and achieve the effect of excellent hand-feeling elasticity and reduced displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Water-based elastic polyurethane emulsion (PU-303 Jiangmen Xinsheng Chemical)

[0029] Ethylene-vinyl acetate (ethylene-vinyl acetate, EVA, Elvax 40W, DuPont)

[0030] Polymethyl methacrylate (Jinan Rongfeng Chemical)

[0031] Matting Powder (OK520 Evonik)

[0032] Elastic powder (5070D Japan Dainichi Seika)

[0033] Water-based hand feel additive (XR-301 Xirun Chemical)

[0034] Wax powder (polytetrafluoroethylene wax powder SST-3 American clover)

[0035] Color paste (water-based resin-free nano black paste Foshan Sansheng Chemical)

[0036] Dispersant (PX4585 BASF)

[0037] Defoamer (NXZ Corning Chemicals)

[0038] Leveling agent (57 Hymings Chemical)

[0039] Neutralizer (DMAE Hymings Chemicals)

[0040] Hydrated Magnesium Silicate (AD Haiyi Chemical)

[0041] Co-solvent (Ethylene Glycol Monobutyl Ether, American Dow)

[0042] HDI hydrophilic isocyanate (2655 Bayer, Germany)

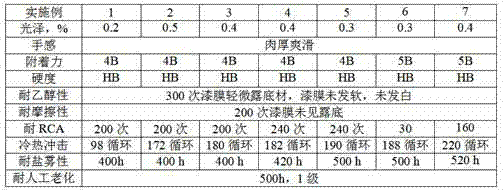

[0043] The ratio of the components in each embodiment is shown in Table 1.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com