High elasticity silica-gel breast prosthesis filler and preparation thereof

A breast prosthesis and silicone gel technology, applied in the field of breast prosthesis, can solve the problems of difficult adjustment of flexibility and shape retention, low elasticity, unnatural hand feeling, etc., and achieve a good natural shape, soft hand feeling and good elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

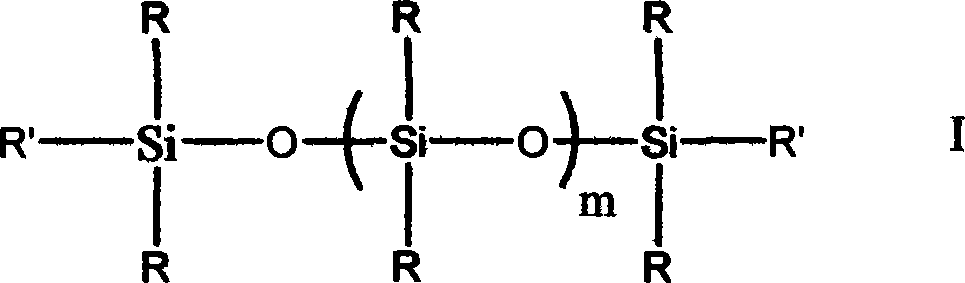

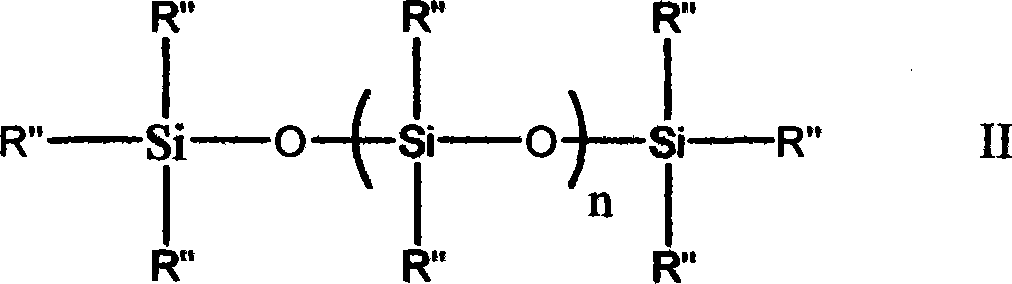

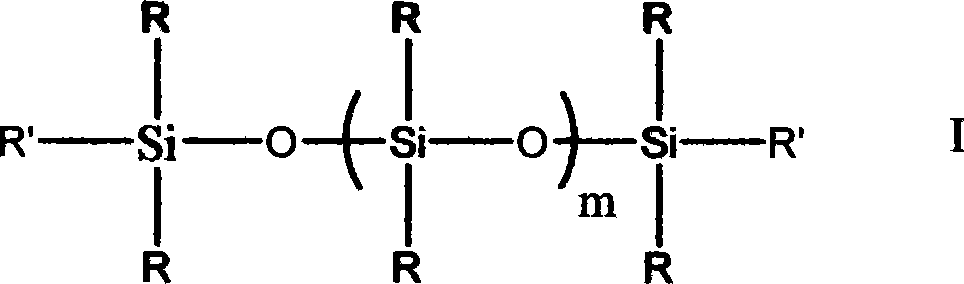

Method used

Image

Examples

Embodiment 1

[0032] Mix the two components A and B according to the weight ratio of 1:1, the total weight is 200g, then add 0.385g of crosslinking agent and 0.05g of catalyst, mix well, degas in vacuum, and then heat at 100±5℃ for 3h to vulcanize ; Wait for it to cool down, put it in a constant temperature box at 25°C and let it stand for 24 hours at a constant temperature, and measure the penetration of the silicone gel to be 8.7mm. Take part of the gel and degas it, inject it into the outer capsule of the breast prosthesis, heat and vulcanize it, and observe its feel and elasticity after cooling.

Embodiment 2

[0034] Mix the two components A and B according to the weight ratio of 2:1, the total weight is 200g, then add 0.365g of crosslinking agent and 0.05g of catalyst, mix well, degas in vacuum, and then heat at 100±5℃ for 3h to vulcanize ; Wait for it to cool down, put it in a constant temperature box at 25°C and let it stand for 24 hours at a constant temperature, and measure the penetration of the silicone gel to be 11.59mm. Take part of the gel and degas it, inject it into the outer capsule of the breast prosthesis, heat and vulcanize it, and observe its feel and elasticity after cooling.

Embodiment 3

[0036] Mix the two components A and B according to the weight ratio of 2:1, the total weight is 200g, then add 0.375g of crosslinking agent and 0.05g of catalyst, mix well, degas in vacuum, and then heat at 100±5℃ for 3h to vulcanize ; Wait for it to cool down, put it in a constant temperature box at 25°C and let it stand for 24 hours at a constant temperature, and measure the penetration of the silicone gel to be 10.82mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com