Coating for blades of wind generation set

A technology of wind turbines and coatings, applied in the field of coatings, can solve problems such as impact and damage on blade surfaces, affecting the service life of wind turbines, and poor wind and sand resistance, and achieve outstanding stone impact resistance, excellent elasticity, and flexibility Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

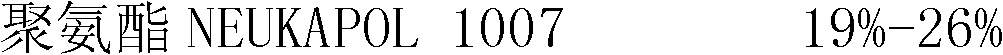

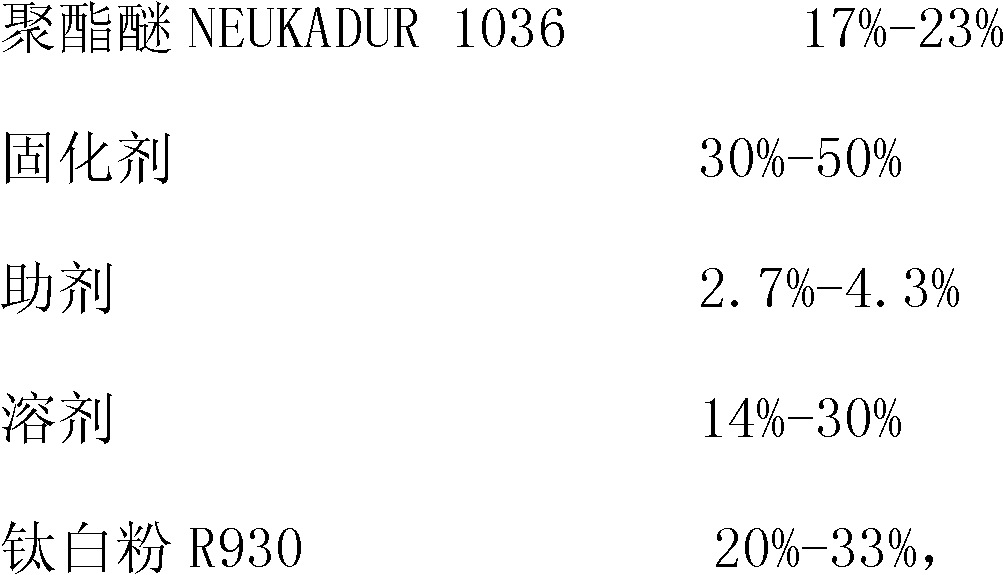

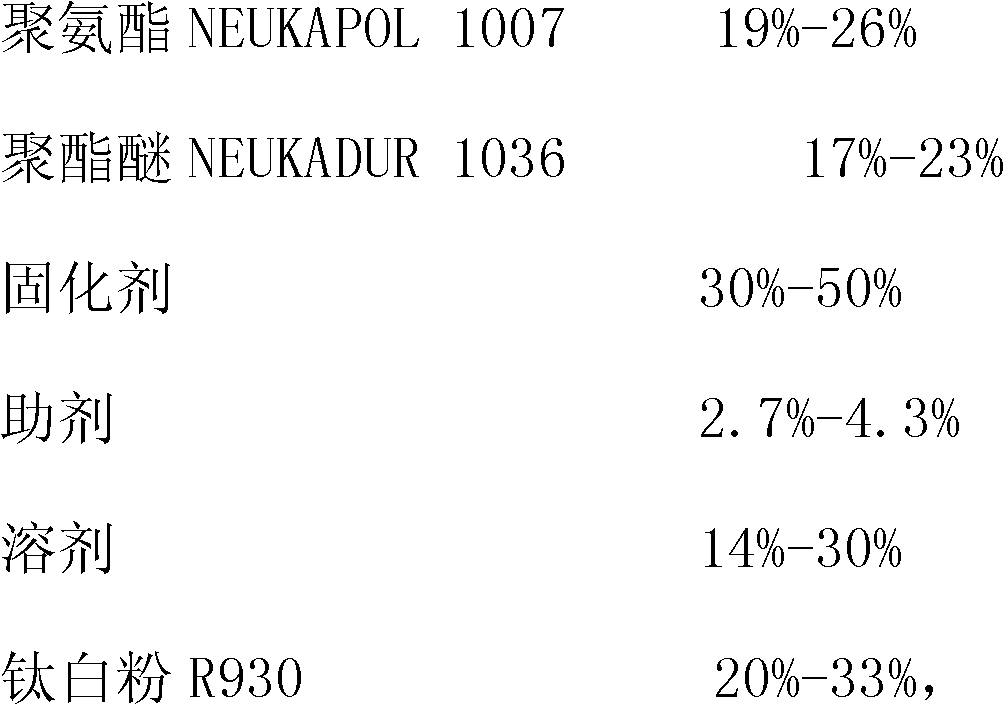

[0021] A coating for wind turbine blades, consisting of the following components (by volume percentage):

[0022] Polyurethane NEUKAPOL 100719.7%; polyester ether NEUKADUR 103623%; curing agent aliphatic polyisocyanate 35%; additives 3.3%; solvent 14%; : 100# solvent oil: MPA = 3: 1: 1 (volume ratio); additives consist of the following components: dispersant BYK 161, anti-settling agent ThixatrolST, anti-sagging agent 6900-HV, leveling agent BYK 300, disinfectant Foaming agent Tego Airex 940; Dispersing agent BYK 161: Anti-settling agent Thixatrol ST: Anti-sagging agent 6900-HV: Leveling agent BYK 300: Defoaming agent TegoAirex 940=4:8:2:3:1.5 (volume ratio) . Weigh the polyester and part of the solvent according to the proportion of the formula, add pigment titanium dioxide, disperse and grind until the particle size is ≤25μm, then add additives and solvents, stir and disperse evenly, and prepare the paint.

[0023] According to the National Paint Quality Supervision and In...

Embodiment 2

[0025] A coating for wind turbine blades, which consists of the following components (by volume percentage): polyurethane NEUKAPOL 100722%, polyester ether NEUKADUR 103617.3%, curing agent 42.5%, auxiliary agent 2.5%, solvent 17%, titanium dioxide R930 20%, The solvent is composed of butyl ester, MPA, 100# solvent oil, butyl ester: 100# solvent oil: MPA=3:1:1 (volume ratio); the auxiliary agent is composed of the following components: dispersant BYK 161, anti-sedimentation agent Thixatrol ST , Anti-sagging agent 6900-HV, Leveling agent BYK 300, Defoamer Tego Airex 940: Dispersant BYK 161: Anti-settling agent Thixatrol ST: Anti-sagging agent 6900-HV: Leveling agent BYK 300: Defoamer Tego Airex 940 = 4:8:2:3:1.5 (volume ratio). Weigh the polyester and part of the solvent according to the proportion of the formula, add pigment titanium dioxide, disperse and grind until the particle size is ≤25μm, then add additives and solvents, stir and disperse evenly, and prepare the paint. A...

Embodiment 3

[0027] A coating for wind turbine blades, consisting of the following components (by volume percentage):

[0028] Polyurethane NEUKAPOL 1007 26%, polyester ether NEUKADUR 1036 17%, curing agent 46%, auxiliary agent 2.7%, solvent 14%, titanium dioxide R930 20.3%; solvent is composed of butyl ester, MPA, 100# solvent oil, butyl ester: 100# solvent oil: MPA=3:1:1 (volume ratio); additives are composed of the following components: dispersant BYK 161, anti-settling agent Thixatrol ST, anti-sagging agent 6900-HV, leveling agent BYK 300, disinfectant Foaming agent Tego Airex 940; Dispersing agent BYK 161: Anti-settling agent ThixatrolST: Anti-sagging agent 6900-HV: Leveling agent BYK 300: Defoaming agent Tego Airex 940=4:8:2:3:1.5 (volume ratio) . Weigh the polyester and part of the solvent according to the proportion of the formula, add pigment titanium dioxide, disperse and grind until the particle size is ≤25μm, then add additives and solvents, stir and disperse evenly, and prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com