Method for preparing high orientation graphene aerogel

A graphene airgel and high-orientation technology, which is applied to ceramic products, other household utensils, household utensils, etc., can solve the problems of lack of graphene dispersion system pretreatment and pre-orientation, poor product structure order, etc., and achieve good The effects of elasticity, ease of handling, and excellent thermal and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Add 1g of graphene, 6g of water, and use 12KHz ultrasonic treatment for 1 hour at 24°C to obtain a graphene dispersion;

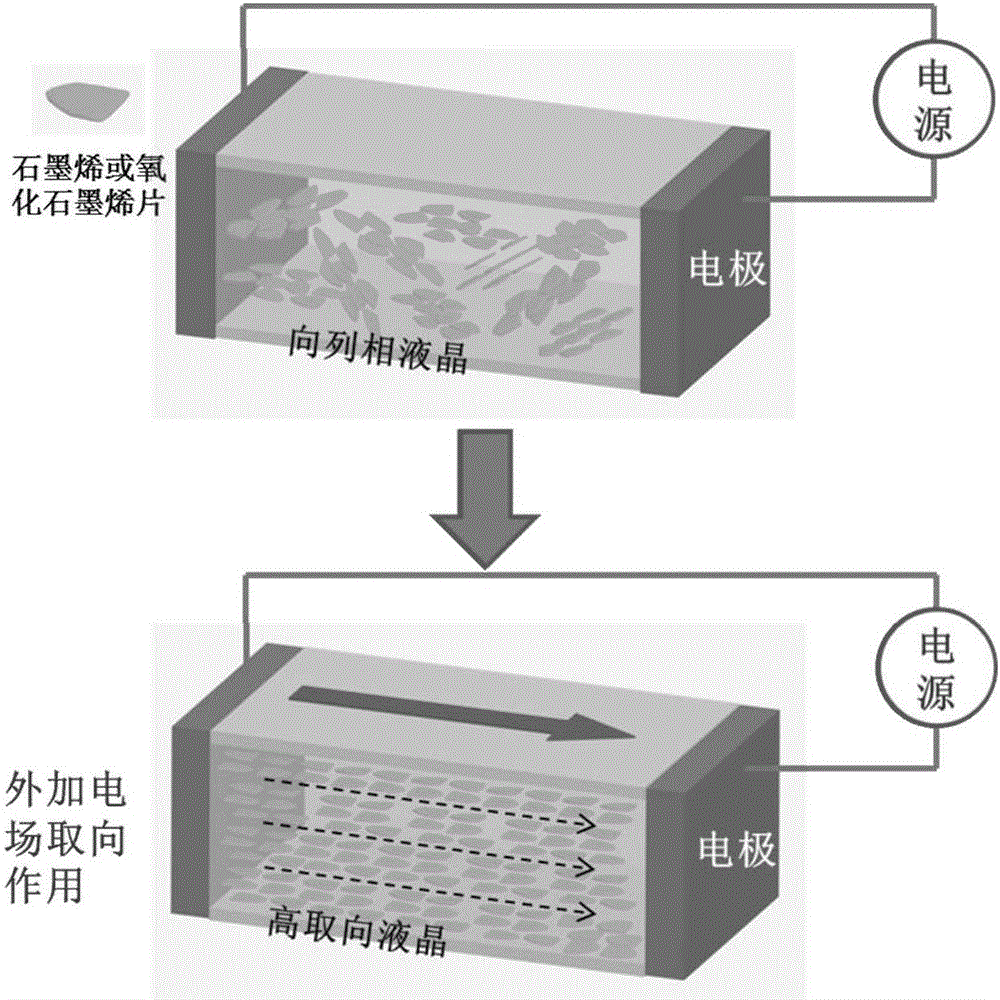

[0036] (2) the graphene dispersion that step (1) is obtained is placed in the container with electrode, is 1000Hz by frequency, and the applied electric field that strength is 2000V / m is oriented to solution 100 minutes, obtains the highly oriented graphene dispersion;

[0037] (3) The highly oriented graphene dispersion liquid that step (2) obtains is continued to maintain the action of the electric field, frozen and solidified in liquid nitrogen, and then further freeze-dried or critically freeze-dried for 40 hours to obtain a highly oriented graphene aerogel;

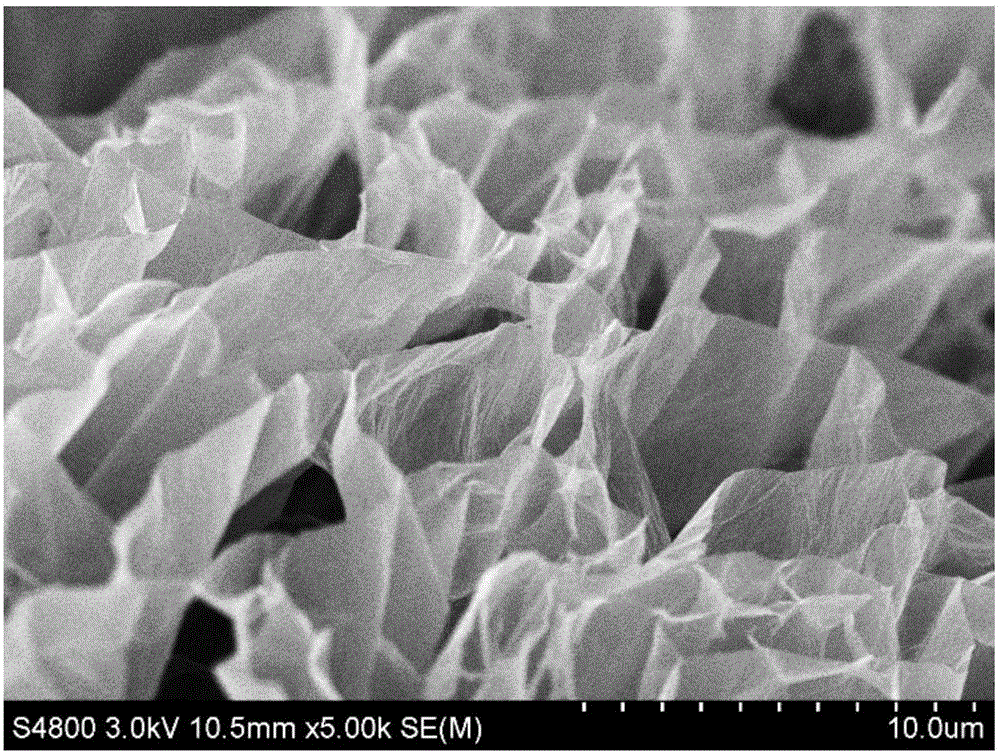

[0038] Such as figure 2 As shown, the obtained highly oriented graphene airgel, the graphene is oriented and arranged to form through holes along the direction of the electric field, and the density is 0.2g / cm 3 , the compressive strength perpendicular to the direction of the orientat...

Embodiment 2

[0040] (1) Add 1g of graphene, 100g of water, and obtain a graphene dispersion at 60° C. with 5KHz ultrasonic treatment for 10 hours;

[0041] (2) the graphene dispersion prepared by step (1) is placed in a container with electrodes, and the frequency is 50 Hz, and an applied electric field with an intensity of 1000 V / m is oriented to the solution for 80 minutes to obtain a highly oriented graphene dispersion;

[0042] (3) The highly oriented graphene dispersion obtained in step (2) is kept under the action of an electric field, frozen and solidified in liquid nitrogen, and then further freeze-dried or critically freeze-dried for 3 hours to obtain a highly oriented graphene aerogel;

[0043] The obtained highly oriented graphene airgel, the graphene is oriented and arranged to form through holes along the direction of the electric field, and the density is 0.01g / cm 3 , the compressive strength perpendicular to the orientation electric field direction is 1MPa, the orientation d...

Embodiment 3

[0045] (1) Add 1g of graphene oxide, 30g of water, and use 10KHz ultrasonic treatment for 5 hours at 40°C to obtain a graphene oxide dispersion;

[0046] (2) Place the graphene oxide dispersion prepared in step (1) in a container with electrodes, and pass an applied electric field with a frequency of 500 Hz and an intensity of 2000 V / m to orient the solution for 50 minutes to obtain highly oriented graphene oxide dispersion liquid;

[0047] (3) The highly oriented graphene oxide dispersion obtained in step (2) is continuously maintained under the action of an electric field, frozen and solidified in liquid nitrogen, and then further freeze-dried for 25 hours to obtain a highly oriented graphene oxide aerogel;

[0048] (4) the ordered porous graphene oxide airgel obtained in step (3) is reduced by heat treatment to obtain ordered porous graphene oxide airgel;

[0049] The obtained highly oriented graphene airgel, the graphene is oriented and arranged to form through holes along ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com