High-elasticity non-woven fabric and manufacturing equipment thereof

A technology for manufacturing equipment and non-woven fabrics, which is applied in the field of high-elastic non-woven fabrics and its manufacturing equipment, which can solve the problems of non-woven fabrics such as difficulty in elasticity, and achieve the effect of good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention provides a highly elastic non-woven fabric, which utilizes the characteristics of thermoplastic polyurethane elastomer, which has the advantages of high elasticity, small deformation, and good air permeability, and has been widely used in clothing and hygienic materials , sports materials, etc., the thermoplastic polyurethane elastomer is formed into an intermediate fiber layer by hot-melt method, and the upper surface layer or the lower surface layer are respectively attached to the upper and lower surfaces of the intermediate fiber layer. The upper and lower surface layers can be made of wool fiber and / or Or wood pulp fiber, such a non-woven fabric has better elasticity and other properties are preserved, and is suitable for fields that require better elasticity.

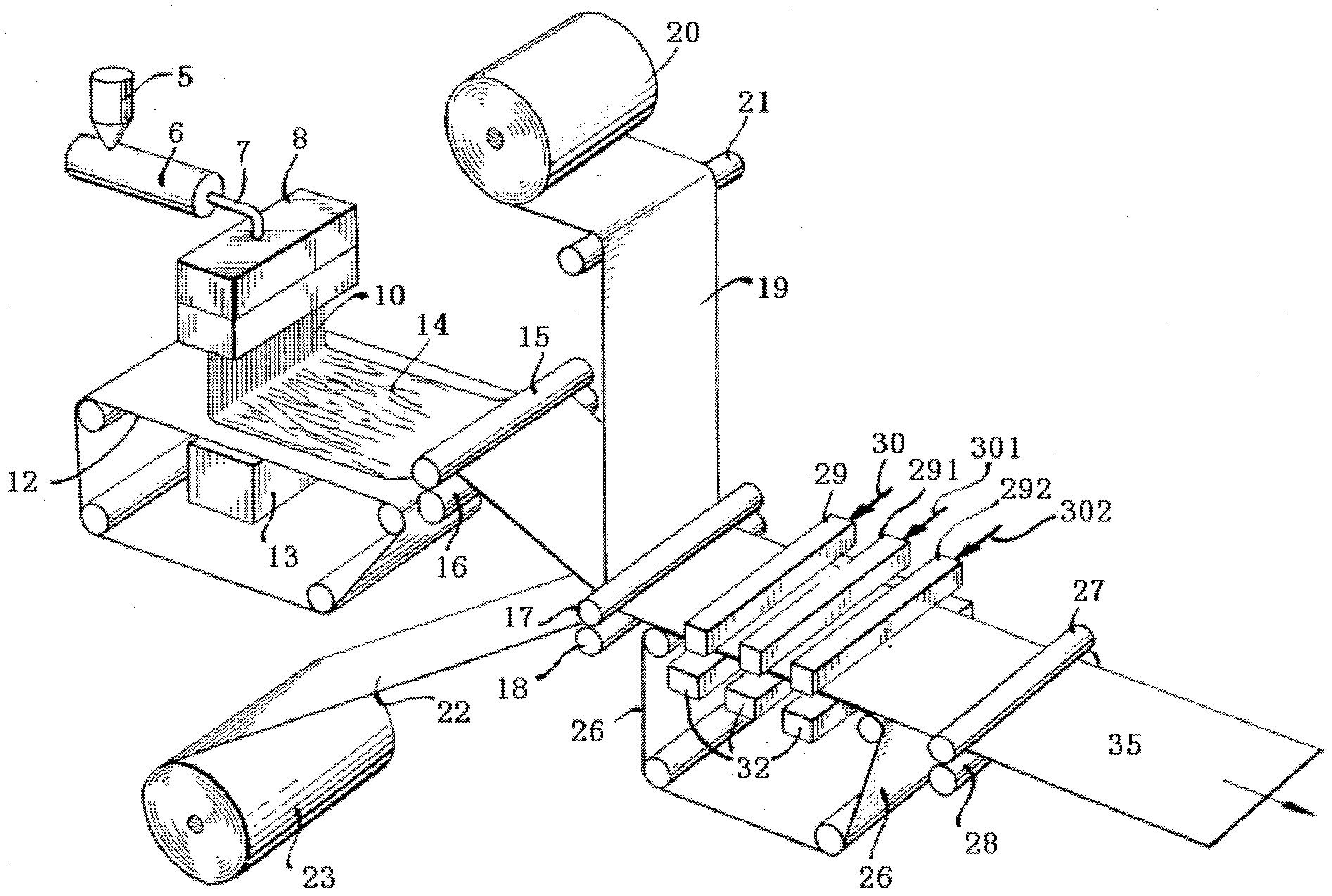

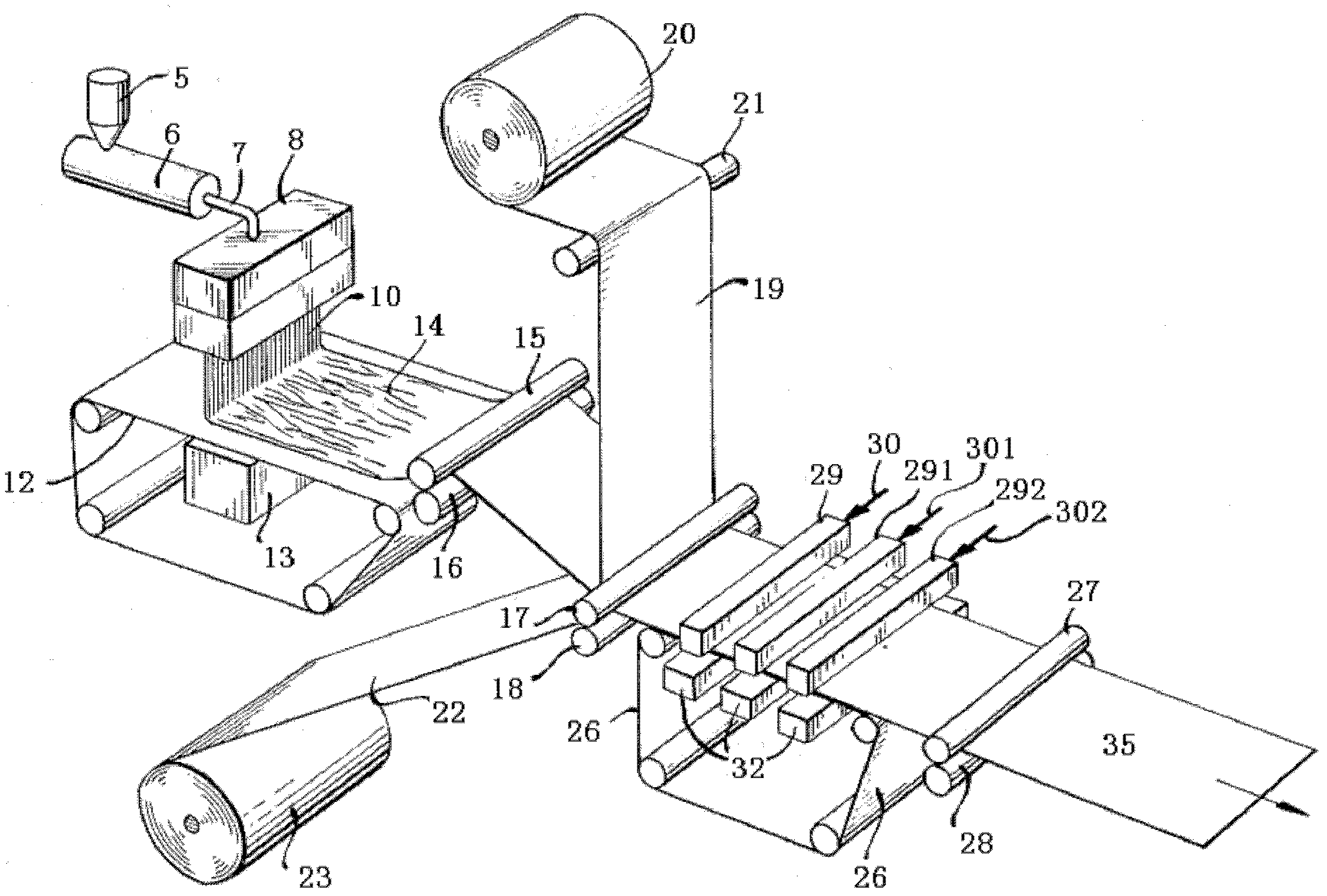

[0020] see figure 1 , showing the high elastic nonwoven manufacturing equipment of the present invention, the manufacturing equipment comprises:

[0021] Hot-melt device, this hot-melt device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nozzle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com