Production method for PTT (Poly Trimethylene terephthalate)/PET (Poly Ethylene Terephthalate) side-by-side composite elastic short fibers

A production method and short fiber technology, which is applied in the production field of PTT/PET side-by-side composite elastic short fibers, can solve the problems of small elasticity and no elasticity, and achieve the effects of good elasticity, soft hand feeling and high bulkiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

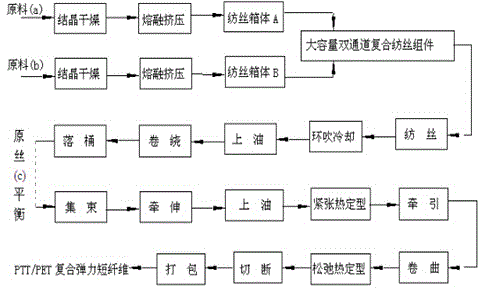

[0018] see figure 1 , in Example 1 of the present invention, the production of 2.0dtex×38mm side-by-side PTT / PET composite elastic short fibers:

[0019] Firstly, 5.85dtex composite precursors are produced, with side-by-side cross-section, moisture content range of 24.5%, and elongation at break range of 450-550%. After the filaments are drawn, they are oiled before the tension setting machine after bundled and drawn. The device performs oiling treatment on the composite tow after drawing. After oiling, the tow enters the crimper for further crimping performance enhancement, and then enters relaxation heat setting for oil curing and tow orientation setting. The shaped tow passes through The conveyor belt is directly sent to the cutting machine for cutting, and then sent to the baler for packaging to obtain 2.0dtex×38mm non-mechanical crimp PTT / PET side-by-side composite elastic short fibers.

Embodiment 2

[0021] see figure 1 , to produce 3.0dtex×51mm medium-length side-by-side PTT / PET composite elastic staple fibers:

[0022] Firstly, 11.50dtex composite precursors are produced, with side-by-side cross-section, moisture content range of 24.5%, and elongation at break range of 500-550%; the precursor yarns are post-drawn, and oiled after the tension setting machine after clustering and drafting The device performs oiling treatment on the drawn composite tow. After oiling, the tow enters the crimping machine for further crimping performance enhancement, and then enters relaxation heat setting for oil curing and tow orientation setting. The tow after shaping is directly Send it to the cutting machine for cutting, and then send it to the baler for packaging to obtain 3.0dtex×51mm medium-length side-by-side PTT / PET composite elastic short fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com