Shredded composite packaging film in arbitrary direction and preparation method thereof

A composite packaging film and extrusion compounding technology, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of affecting the barrier performance of packaging materials, the technical difficulty of cellophane, and the difficulty of product quality control. , to achieve good anti-pollution and heat-sealing properties, good shelf effect, and excellent protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

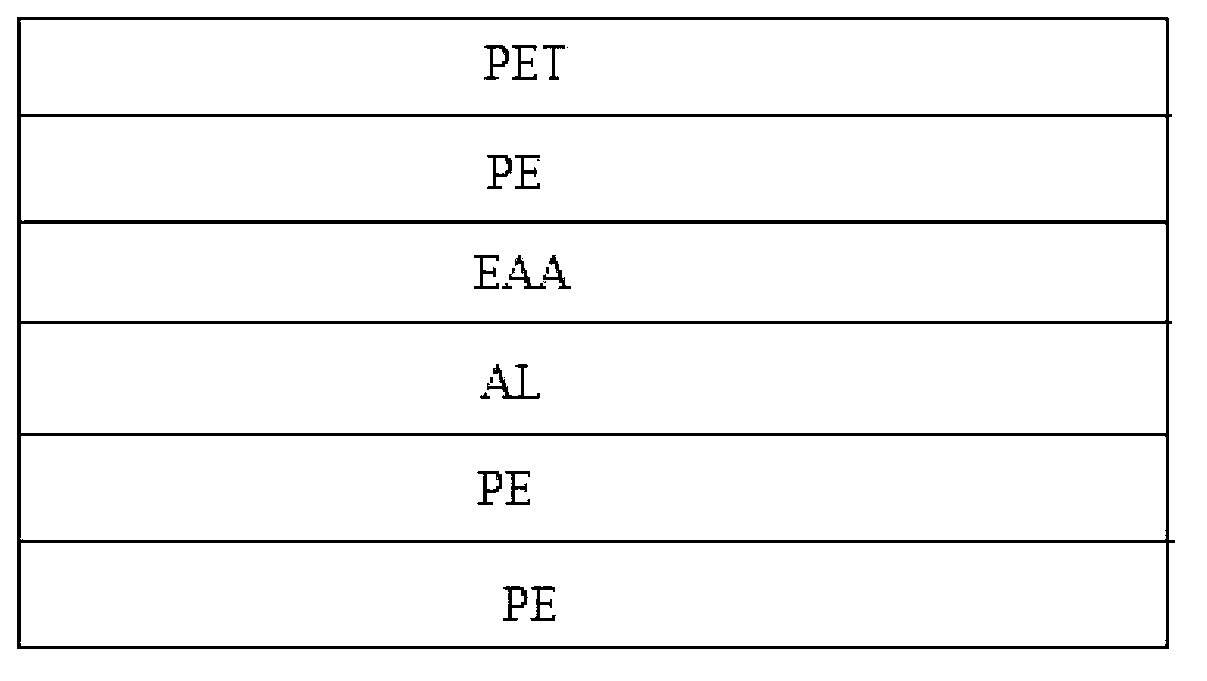

[0031] The hand-tearable composite packaging film in any direction is a PET / PE·EAA / AL / PE / PE composite structure composed of three layers of substrates with different properties.

[0032] see figure 1 shown, where:

[0033] Outer layer: PET (ethylene terephthalate);

[0034] The first protective layer: PE (polyethylene) EAA (ethylene acrylic acid copolymer);

[0035] Barrier layer: AL (aluminum foil);

[0036] Second protective layer: PE (polyethylene);

[0037] Inner layer: PE (polyethylene).

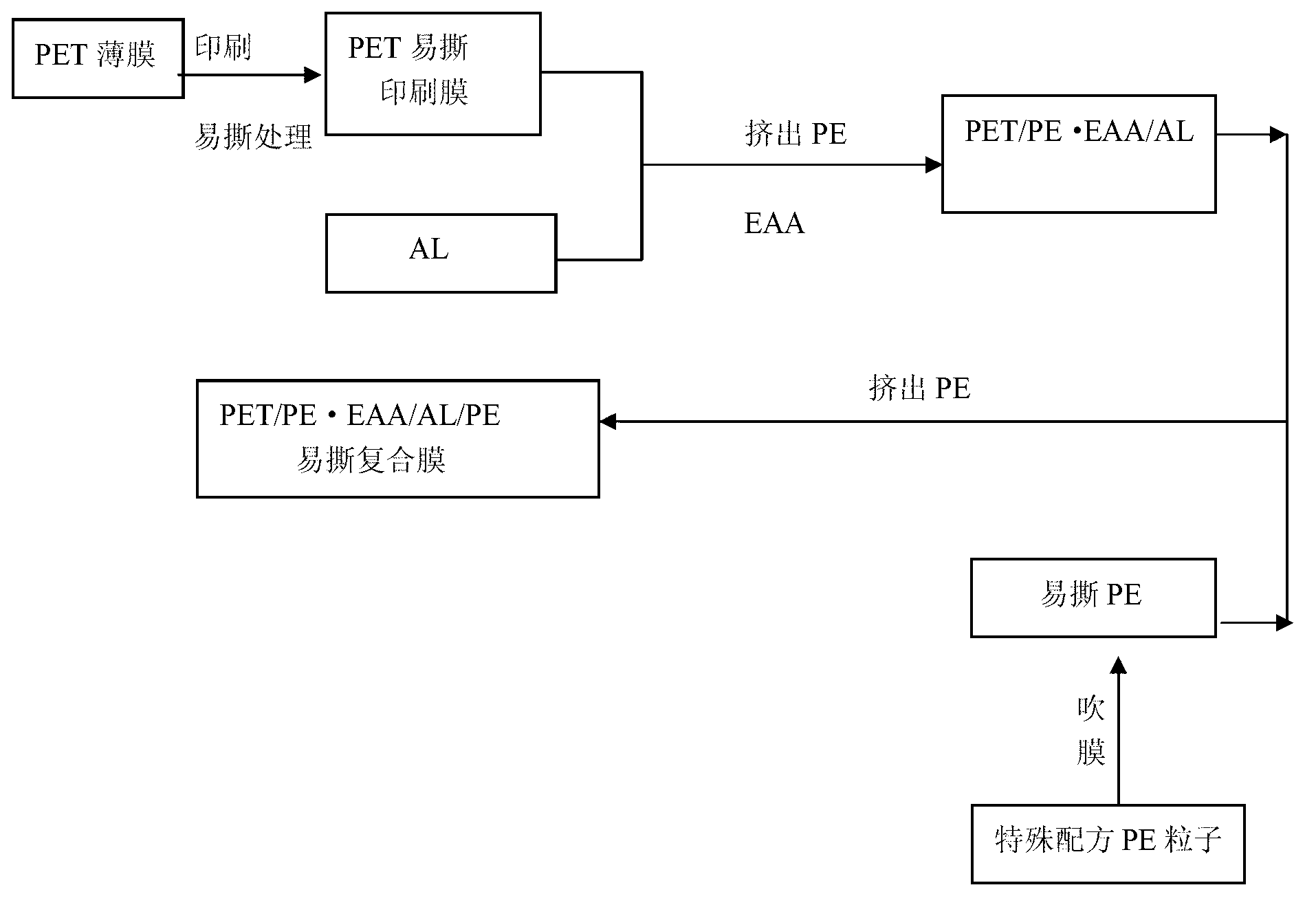

[0038] Please also see figure 2 , the preparation method of the hand-tearable composite packaging film in any direction is as follows:

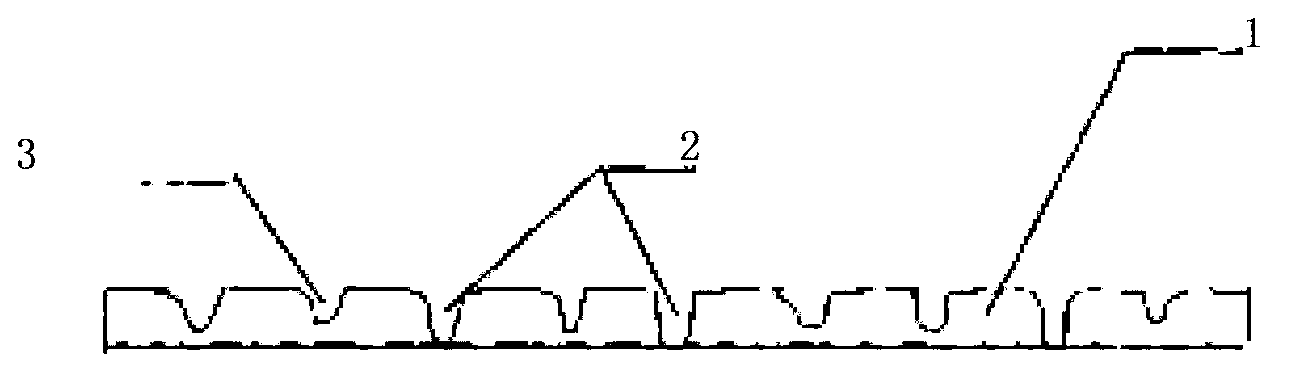

[0039] Step 1: The raw material PET film is printed according to the normal process, and after the printing process is completed, it is transferred to the easy-to-tear process, please refer to image 3 As shown, the PET film substrate 1 is distributed with penetrating micropores 2 and non-penetrating holes 3 to obtain a PET easy-tear printing f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com