Production method of pattern in magnetic pigment fragment-containing coating layer and production device thereof

A magnetic pigment and a technology for generating a device, which are applied in the field of generating patterns and devices in a coating containing magnetic pigment fragments, can solve the problem of forming anti-counterfeiting patterns without considering the orientation of the pigments, difficult to control the arrangement angle of the magnetic fragments and pigments, and considering only the magnetic pigments. Magnetic detection and anti-counterfeiting, etc., to achieve the effect of high anti-counterfeiting function, high manufacturing difficulty and clear pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

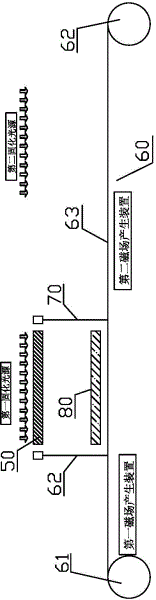

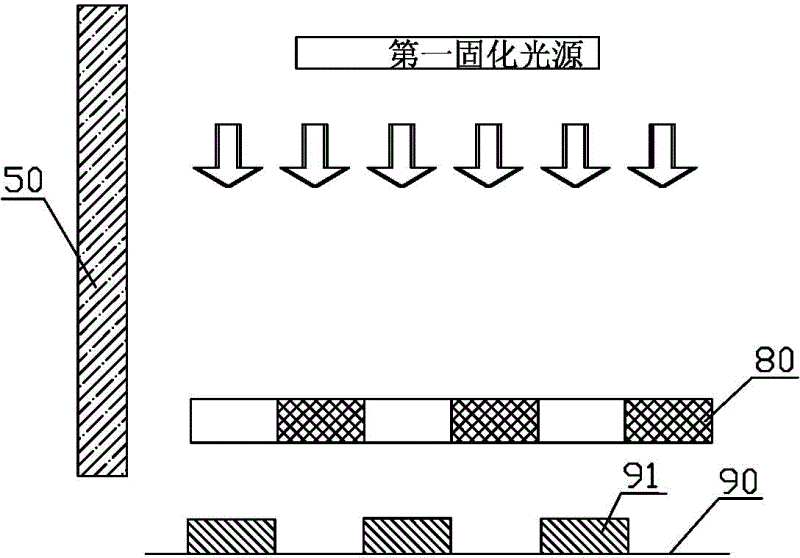

[0048] figure 1 It is a structural schematic diagram of the first embodiment of the device for generating patterns in a coating containing magnetic pigment fragments according to the present invention. Such as figure 1 As shown, the device includes a first magnetic field generating device, a second magnetic field generating device, a first curing light source, a second curing light source, a light blocking plate 50 , a blocking plate 80 and a substrate conveying device 60 . The substrate conveying device 60 includes wheel shafts 61 , 62 arranged at two ends and a conveyor belt 63 driven by the two wheel shafts 61 , 62 . In the direction from the axle 61 to the axle 62, a first magnetic field generating device, a first curing light source, a second magnetic field generating device and a second curing light source are arranged in sequence. The first magnetic field generating device is arranged directly below the substrate conveying device 60; below the first curing light sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com