Digital inkjet thermal transfer printing water-based ink for textiles and preparation method of ink

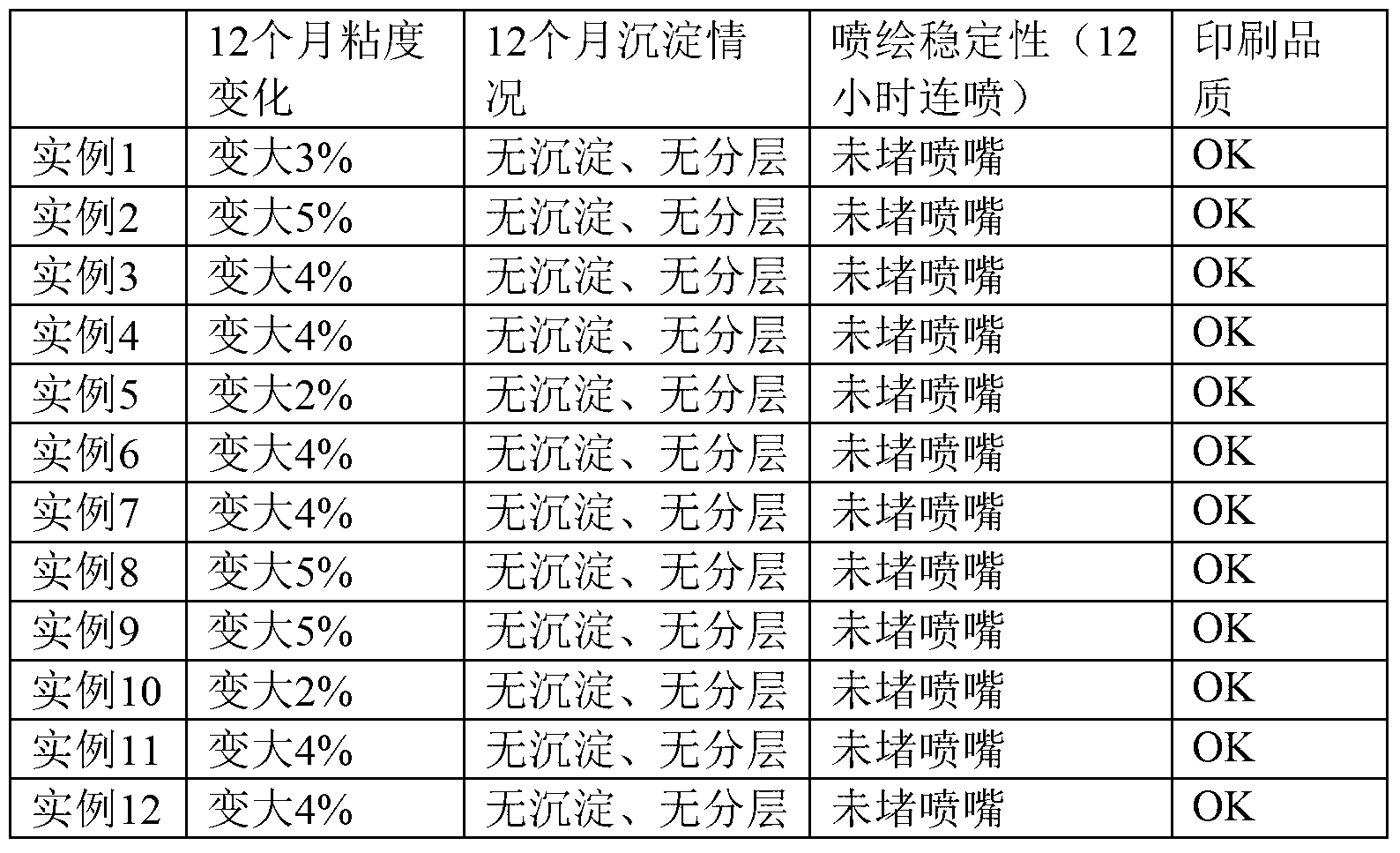

A thermal transfer printing, digital inkjet technology, applied in transfer printing, textile and papermaking, printing, etc., can solve the problems of poor stability, easy to block nozzles, etc., to achieve good stability, high transfer rate and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]Fully dissolve 7 parts of dispersant MF (Shangyu Haili Chemical) and 1 part of dispersant SILCO SPERSE HLD-11 / C (Germany SILCONA Company) in 60 parts of deionized water, then add 0.3 parts of wetting agent Surfynol AD01 (USA Air Chemicals), 15 parts of glycerin, 5 parts of ethylene glycol, 5 parts of isopropanol, 0.2 parts of defoamer Surfynol DF-37 (Air Chemicals, USA) and 0.05 parts of preservative Kathon LXE (Rohm and Haas, USA), After fully stirring and mixing, add 10 parts of Disperse Red 60 (Zhejiang Jihua Group), and stir again to obtain a pre-dispersion. Pass the predispersion through the containing The zirconia beads are refined for 4 times in a horizontal sand mill, filtered through a 150-180 mesh stainless steel filter, and then ultra-finely dispersed by a 120Mpa ultra-high pressure homogenizer for 2 times, so that the particle size of the disperse dye particles is 80- 200nm, nano-membrane (US Pall Company, pore size 0.5μm) filtration, discharge, that is to ...

Embodiment 2

[0030] Fully dissolve 6 parts of dispersant Reax85A (U.S. Westvaco Company) and 2 parts of dispersant PEG600 (polyethylene glycol) in 60 parts of deionized water, then add 0.5 parts of wetting agent SILCO WET D500 (Germany SILCONA Company), 15 parts Glycerin, 5 parts of ethylene glycol, 5 parts of ethanol, 0.3 parts of defoamer Surfynol 110D (Air Chemicals, USA) and 0.02 parts of preservative Nipacide HF-1 (Clariant), mixed in the solution obtained above, mixed thoroughly Finally, add 8 parts of Disperse Red 60 and stir again to obtain a pre-dispersion. Pass the predispersion through the containing The zirconia beads are refined for 4 times in a horizontal sand mill, filtered through a 150-180 mesh stainless steel filter, and then ultra-finely dispersed by a 120Mpa ultra-high pressure homogenizer for 2 times, so that the particle size of the disperse dye particles is 80- 200nm size, nano-membrane (US Pall Company, pore size 0.5μm) filtration, discharge, that is to get water-...

Embodiment 3

[0032] Fully dissolve 7 parts of dispersant NNO and 3 parts of dispersant Pingping plus O in 75 parts of deionized water, then add 0.3 parts of wetting agent Surfynol420 (Air Chemicals of the United States), 15 parts of glycerin, 5 parts of ethylene glycol, and 5 parts of iso Propanol, 0.3 parts of defoamer Surfynol DF-37 (Air Chemicals, USA) and 0.05 parts of preservative Kathon LXE (Rohm and Haas, USA) were mixed in the solution obtained above. Red 60, stir well again to obtain a pre-dispersion. Pass the predispersion through the containing The zirconia beads are refined for 4 times in a horizontal sand mill, filtered through a 150-180 mesh stainless steel filter, and then ultra-finely dispersed by a 120Mpa ultra-high pressure homogenizer for 2 times, so that the particle size of the disperse dye particles is 80- 200nm size, nano-membrane (US Pall Company, pore size 0.5μm) filtration, discharge, that is to get water-based digital inkjet thermal transfer printing ink. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com