Production method of two-needle bed baseless jacquard sandwich fabric

A technology of jacquard sandwich and production method, which is applied in the field of fabric textiles, and can solve the problems of not being able to independently form a piece of fabric and having no light and thin feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Through the CAD software, design the pattern of the bottomless jacquard sandwich fabric, including the plain area and the mesh area, and convert the Jacquard artisan information designed by CAD into a double-needle single Jacquard knitting machine that can be recognized Machine file, and input it into the double-needle bed single jacquard Raschel warp knitting machine whose machine number is E24;

[0030] (2) Use double-needle bed single jacquard Raschel warp knitting machine to weave gray fabric, during the weaving process:

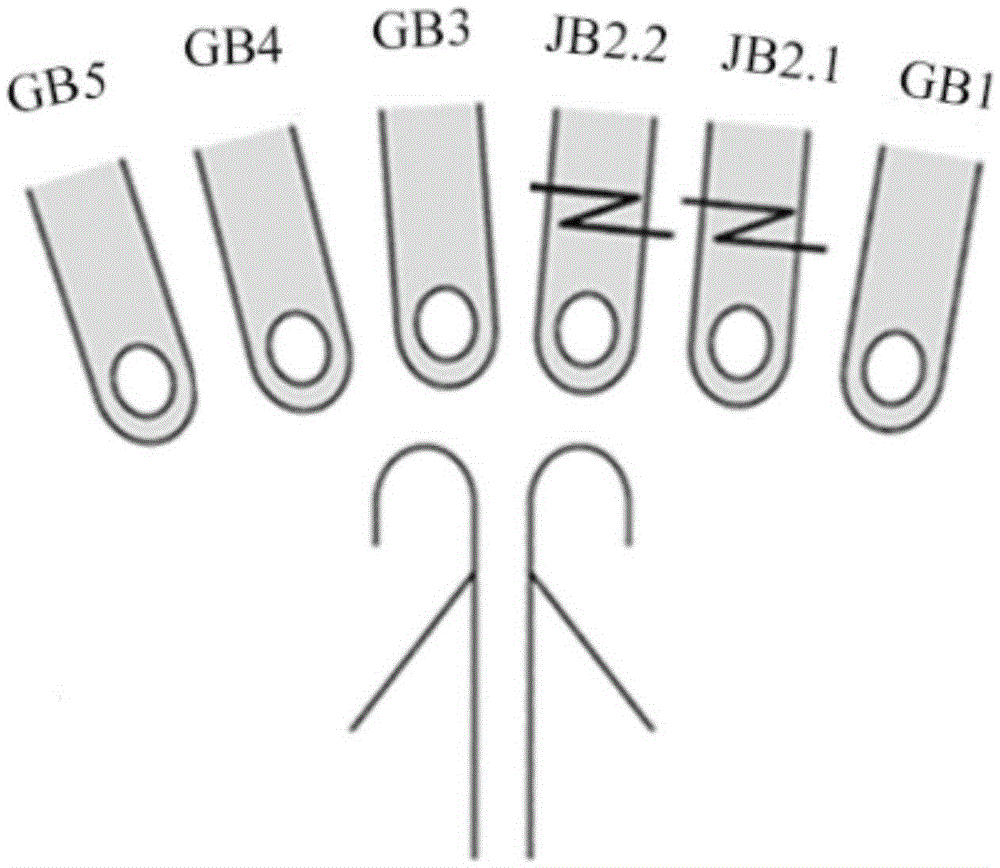

[0031] The gauge between the front needle bed and the rear needle bed is set to 4.5mm; the bars of the warp knitting machine are arranged in sequence as follows: from the front needle bed to the rear needle bed, the elastic bar GB1 of the front needle bed and two Jacquard bars of the front needle bed are arranged sequentially. Bars JB2.1, JB2.2, spacer yarn guide bar GB3, two rear needle bed ground bars GB4, GB5;

[0032] Insert 40D spandex y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com