Transfer printing type ultraviolet light curing ink composition, preparation method thereof and mobile phone casing using ink composition

An ink composition, ultraviolet light technology, applied in the direction of ink, application, household appliances, etc., can solve problems such as poor adhesion, shrinkage of product edges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

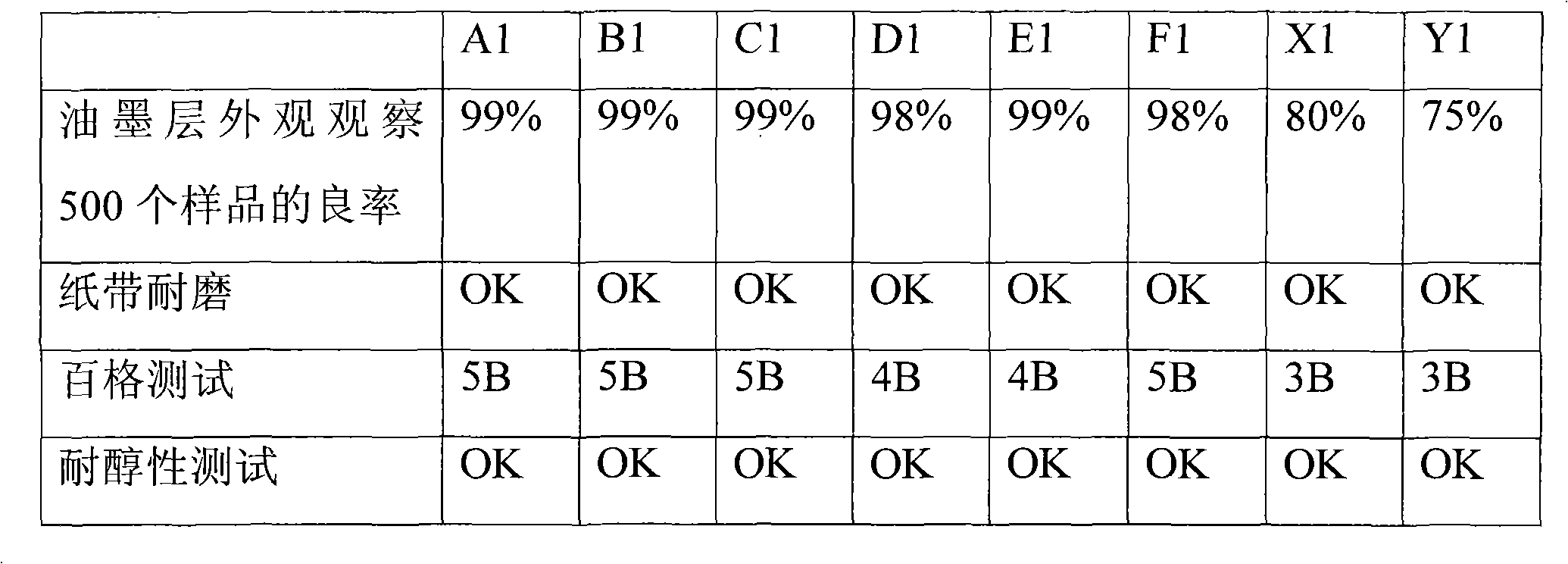

Examples

Embodiment 1

[0036] The formula of the UV-curable ink composition that can be printed in the present invention is:

[0037] Four-functionality polyester acrylic resin 38.5wt%

[0038] Amino-modified acrylic resin 15wt%

[0039] Nine-functionality aliphatic urethane acrylate 10wt%

[0040] 8wt% thermoplastic hydroxyl acrylic resin with hydroxyl value content of 45mgKOH / g

[0041] Thinner UV curing monomer 10wt%

[0042] Photoinitiator 4wt%

[0043] Pigment is carbon black 10wt%

[0044] Defoamer 0.5wt%

[0045] Leveling agent 1.5wt%

[0046] Thixotropic agent is fumed silica 2.0wt%

[0047] Dispersant 0.5wt%

[0048] According to the formula, the components were fully mixed evenly, and ground with a three-roll mill until the fineness was below 10 μm to obtain the pad-printable UV-curable ink composition A1 of the present invention.

[0049] Use a pad printing machine to print on the surface of the varnish layer with a surface energy of 28Dyne / cm, and convey it by a conveyor belt, a...

Embodiment 2

[0051] The difference from Example 1 is that it also contains a second UV curable monomer, and the second UV curable monomer is a trifunctional monomer. Wherein, the content of the four-functional polyester acrylic resin is 30.5 wt%, and the content of the tri-functional monomer is 8 wt%. The pad-printable UV-curable ink composition B1 of the present invention was obtained.

[0052] 500 ink layer B11 samples were obtained by pad printing and curing by a pad printer.

Embodiment 3

[0054] The difference from Example 1 is that it does not contain additives, wherein the content of additives leveling agent, defoamer, thixotropic agent and dispersant are all 0, and the content of chlorinated acrylic resin is 19.5wt%. Because do not contain auxiliary agent so the time of mixing is longer than embodiment 1. The pad-printable UV-curable ink composition C1 of the present invention was obtained.

[0055] 500 ink layer C11 samples were obtained by pad printing and curing by a pad printer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com