Method for producing sheep and rabbit hair combing elastic fabric

A production method and technology of rabbit hair, applied in biochemical fiber processing, textile, yarn, etc., can solve the problems of short length of rabbit hair fiber and difficulty in meeting quality requirements of rabbit hair fiber fabrics, so as to improve quality, product quality and additional The effect of value improvement and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

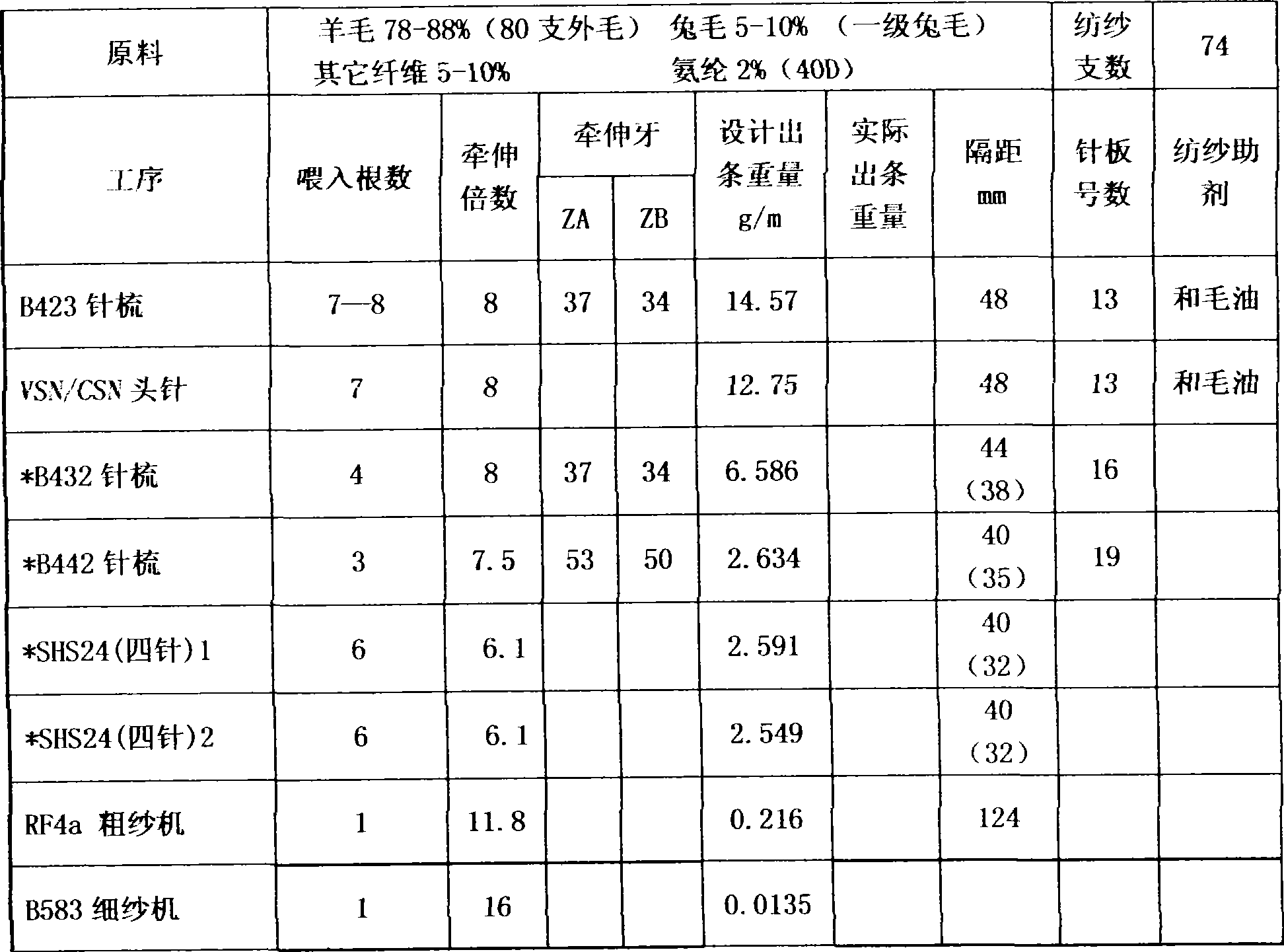

[0040] The production method of sheep and rabbit hair combed elastic fabric of the present invention comprises raw material selection—pretreatment of rabbit hair fiber—spinning process (combed spinning and semi-combed spinning combined)—weaving process—fabric Finishing process, its specific process steps are as follows:

[0041] 1. Raw material selection

[0042] By weight percentage

[0043] Wool: 78-88%

[0044] Rabbit hair: 5-10% of the first grade rabbit hair

[0045] Other fibers: silk or cashmere or tencel 5-10%

[0046] 40D Ammonia On: 2%

[0047] 2. Pretreatment of rabbit hair fiber

[0048] Because the rabbit hair fiber scales are tightly wrapped on the hair shaft, the opening angle of the scale tips is small, there are few docking points between the scales, and the scales are tightly bonded, like a sleeve-like structure, covering the cortical cells inside, and the fiber surface is smooth. The spinnability is poor, so the original rabbit hair textiles are easy t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com