Method for integrating thermal insulation and decoration for small-sized assembled thermal insulation precast slab exterior insulation system

A prefabricated and prefabricated panel technology, applied in thermal insulation, building components, covering/lining, etc., can solve problems such as untapped technical potential, achieve the effects of enriching decoration types and color varieties, improving artistic effects, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

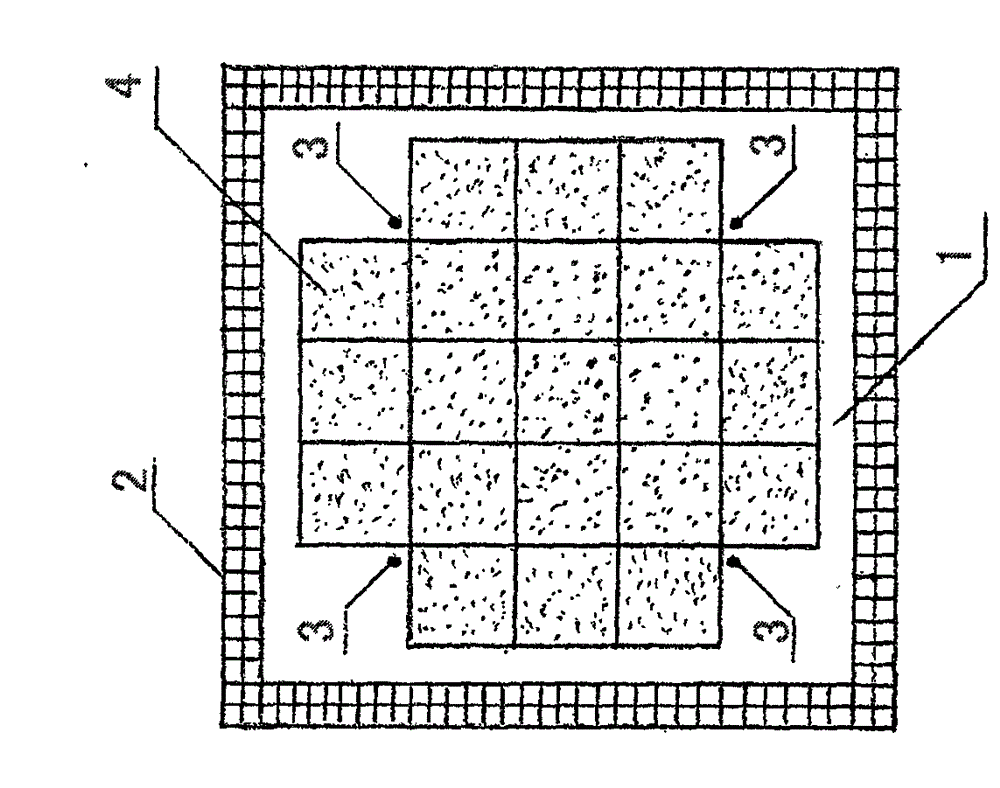

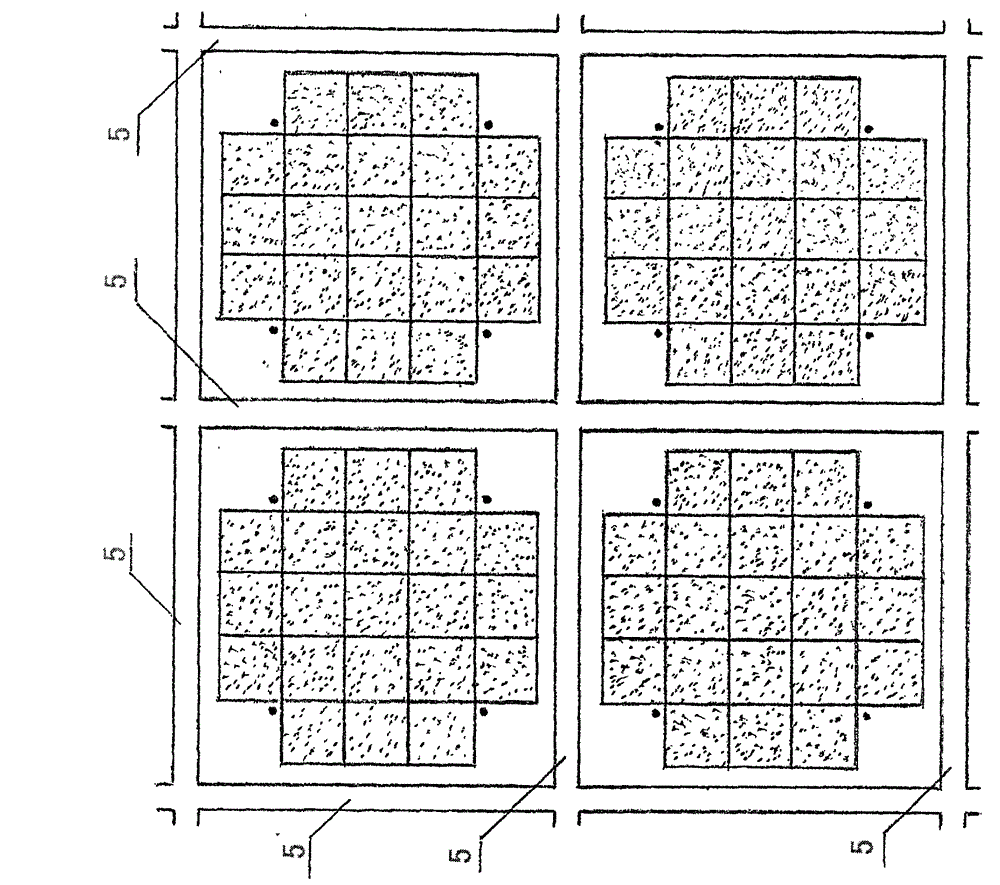

[0025] Such as figure 1 and figure 2 As shown, in the factory, the exterior wall facing brick 4 is pre-attached on the outer surface 1 of the fine aggregate concrete panel, and the facing brick at the lap joint 5 formed by the overlapping of the anchor hole 3 and the steel wire mesh 2 is reserved for the small The prefabricated prefabricated panels for prefabricated insulation are subsidized after being installed on the wall.

[0026] figure 1 The facing bricks shown are square bricks, and the arrangement of the facing bricks is a joint arrangement. If the facing bricks are strip bricks, the arrangement of the facing bricks can also be arranged in a staggered joint.

Embodiment 2

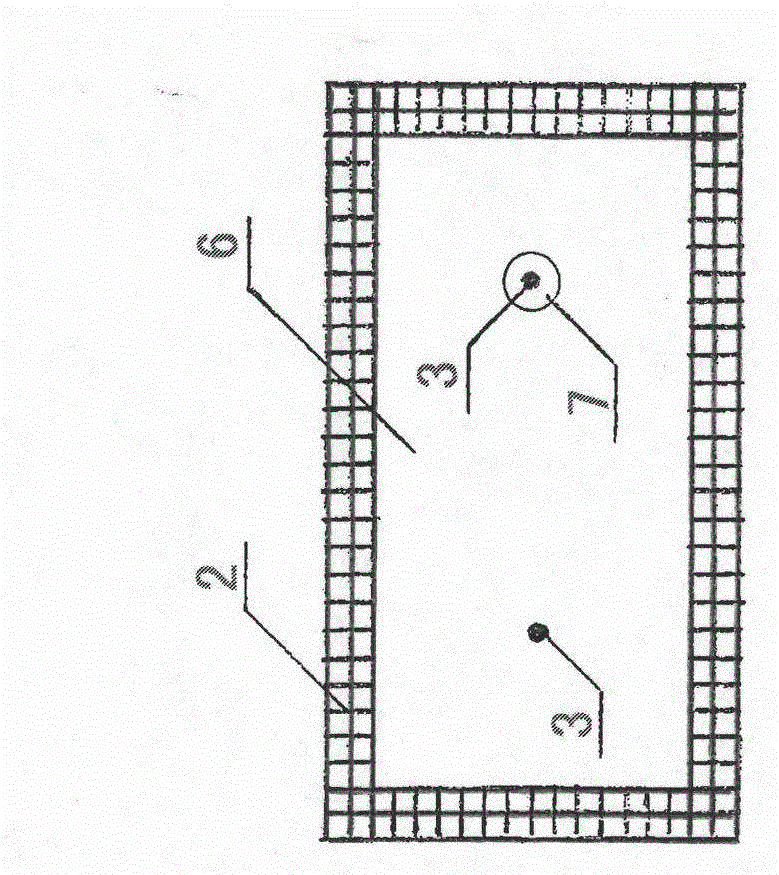

[0028] Such as image 3 and Figure 4 As shown, in the factory, the outer surface of the fine aggregate concrete panel is formed to have a smooth surface and neat corners, and then the exterior wall paint is sprayed on the outer surface of the fine aggregate concrete panel (the position 7 where the small flower decoration is set is vacated, No spraying) to form a paint finish 6; after the small prefabricated thermal insulation board is installed on the wall, the anchor hole 3 is sealed with a suitable color sealing paste, and the position 7 of the small flower decoration is fixed (pasted or mechanically fixed) The decorative sheet forms a small flower decoration 8; the lap joint 5 formed by the overlapping of the steel mesh 2 is smeared into a concave seam with a special mortar, and then painted with an appropriate exterior wall paint, or smeared into a concave seam with a special facing mortar.

[0029] image 3 The finish shown is the finish of spraying paint on the flat b...

Embodiment 3

[0031] such as 5 and Figure 6 As shown, in the factory, the concrete for the production of fine aggregate concrete panels uses fine aggregate decorative concrete, or the concrete on the outer surface of the fine aggregate concrete panels uses fine aggregate decorative concrete, and the outer surface of the fine aggregate concrete panels is formed into The surface is smooth and the corners are neat, forming a decorative concrete finish 9, and a small flower decoration 8 is arranged in the middle of the outer surface of the fine aggregate concrete panel; after the small prefabricated prefabricated panel is installed on the wall, the anchor hole 3 is sealed with an appropriate color Paste sealing; the lap joint 5 formed by the overlapping of the steel wire mesh 2 is made into a recess with a special mortar, and then painted with an appropriate color of exterior wall paint, or made into a recess with a special finishing mortar.

[0032] Figure 5 The finish shown is a flat decor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com