Gauge leveling device

A technology of squares and leveling strips, which is applied in the field of leveling devices for squares, can solve problems such as low quality leveling of squares, leveling of squares, damage to ground decoration materials, etc., to achieve improved quality, high flatness and verticality, Installation for reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

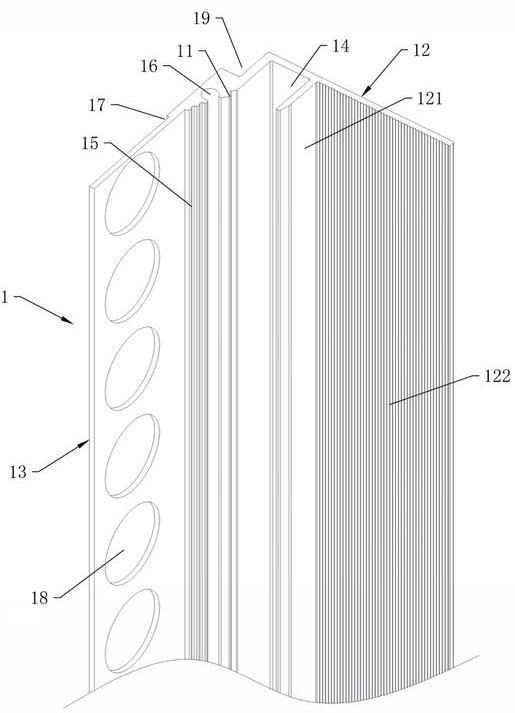

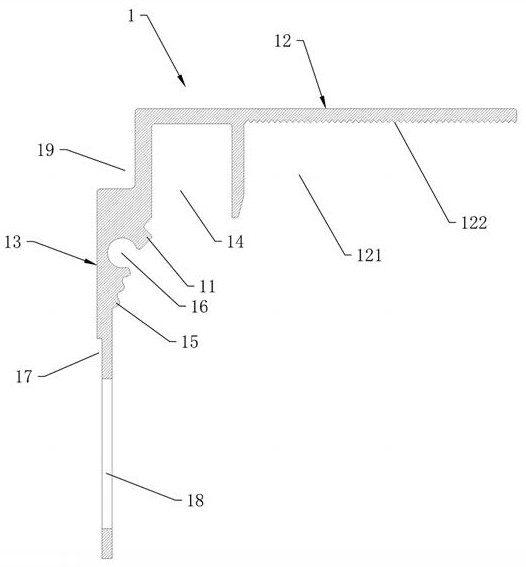

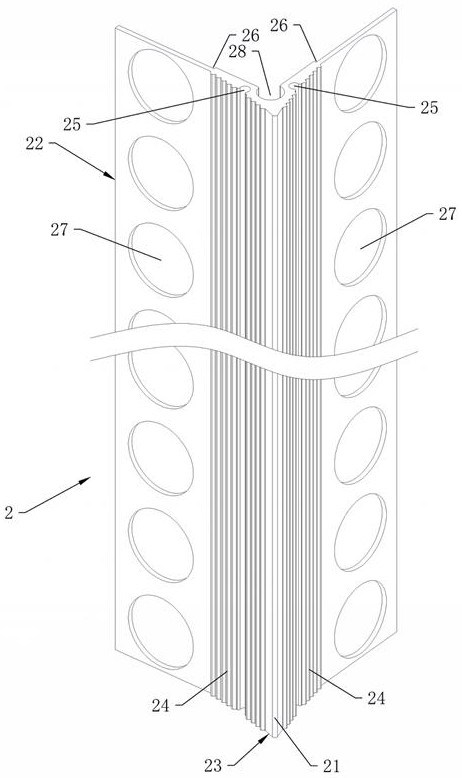

[0070] Such as Figure 1 to Figure 12 As shown, a square leveling device according to the present invention includes a pre-embedded ceiling line 1, a pre-buried male corner line 2, a pre-buried female corner line 3, a pre-buried leveling strip 4, and a pre-buried invisible Telescopic skirting line 5, wherein the radial sections of the embedded ceiling line 1, the embedded male corner line 2 and the embedded female corner line 3 all have an angled structure, and the vertical section of the embedded ceiling line 1 A first reference convex line 11 is provided on the inner surface, a second reference convex line 21 is provided on the outer corner of the embedded male corner line 2, and the two inner surfaces of the embedded internal corner line 3 are respectively A third datum ridge 31 is set, a fourth datum ridge 41 is set on the outer surface of the pre-embedded leveling strip 4, and a fifth datum ridge is set on the outer surface of the pre-embedded invisible telescopic skirtin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com