Printing and embossing synchronous forming method and device for polyester compound fabric

A composite fabric and forming device technology, which is applied in the textile industry, can solve the problems of unclear printing patterns and poor texture of embossed products, and achieve the effect of clear patterns, strong texture and guaranteed product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

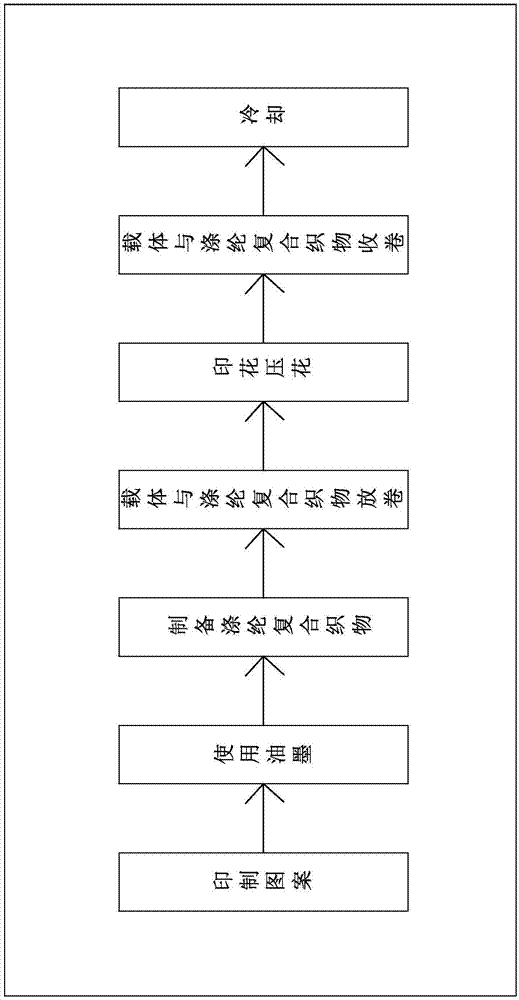

[0035] Such as figure 1 As shown, a. Printed pattern: Choose a carrier. In this embodiment, a high-temperature resistant PET film is used as the carrier, and the length is taken as 100m, and it is printed on a gravure printing machine. The required printing patterns are printed on the film; the heat-resistant temperature of the high-temperature resistant PET film is above 220°C, and the heat-resistant time is above 30s. The high-temperature resistant PET film has a smooth surface and has no affinity for disperse dyes during the heat transfer process.

[0036] b. Ink used: heat transfer printing ink is used for the high temperature resistant PET film with pattern in step a. The ink used in this implementation is alcohol-soluble disperse dye ink and is dried at the same time. In this implementation, the drying temperature is 80°C. ;

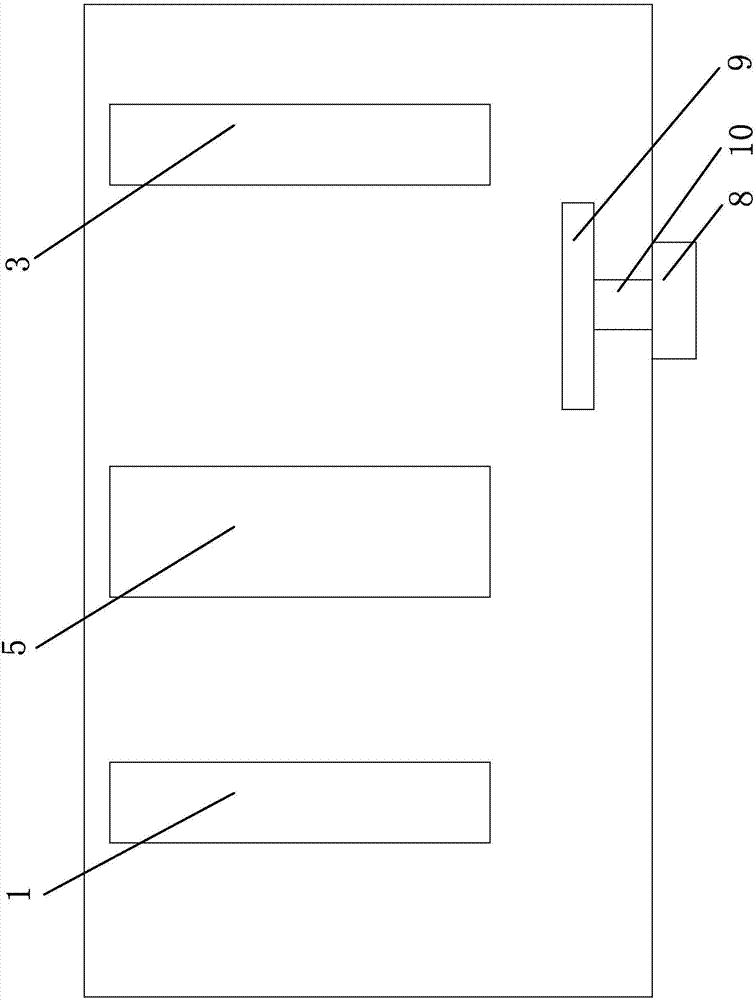

[0037] c. Preparation of polyester composite fabric: 165g / m for the surface layer 2 Warp knitted polyester microfiber fabric, the bottom layer is 210g / ...

Embodiment 2

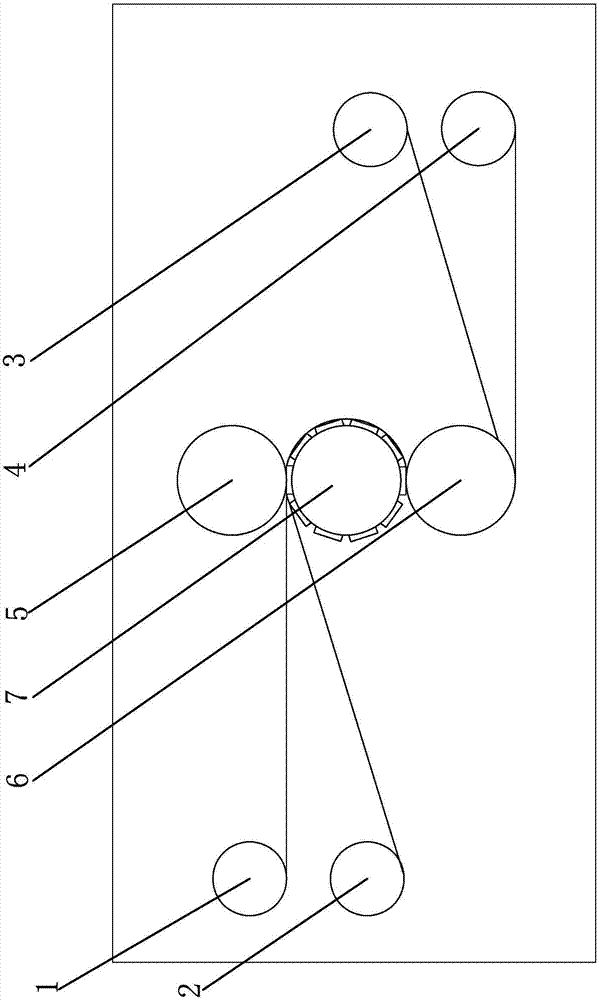

[0044] The structure and principle of this embodiment are basically the same as those of the first embodiment. The difference lies in: in the first embodiment, b. Use ink: use the ink for thermal transfer printing on the high temperature resistant PET film with pattern in step a, The ink used is alcohol-soluble disperse dye ink, dried at the same time, and the drying temperature is 80℃; c. Preparation of polyester composite fabric: 165g / m for the surface layer 2 Warp knitted polyester microfiber fabric, the bottom layer is 210g / m 2 Weft-knitted polyester double-sided fleece fabric, using PUR hot melt adhesive to prepare a polyester composite fabric, standby; e, printing embossing: at a pressure of 8MPa, a temperature of 180 ℃, through the action of the upper pressure roller and embossing roller , To realize the primary ink thermal transfer between the high temperature resistant PET film and the polyester composite fabric. Through the action of the lower pressure roller and the em...

Embodiment 3

[0046] The structure and principle of this embodiment are basically the same as those of the first embodiment. The difference lies in: in the first embodiment, b. Use ink: use the ink for thermal transfer printing on the high temperature resistant PET film with pattern in step a, The ink used is alcohol-soluble disperse dye ink, dried at the same time, and the drying temperature is 80℃; c. Preparation of polyester composite fabric: 165g / m for the surface layer 2 Warp knitted polyester microfiber fabric, the bottom layer is 210g / m 2 Weft-knitted polyester double-sided fleece fabric, using PUR hot melt adhesive to prepare a polyester composite fabric, standby; e, printing embossing: at a pressure of 8MPa, a temperature of 180 ℃, through the action of the upper pressure roller and embossing roller , To realize the primary ink thermal transfer between the high temperature resistant PET film and the polyester composite fabric. Through the action of the lower pressure roller and the em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com