Health care type composite fancy yarn and manufacturing method thereof

A fancy yarn and health-care technology, applied in the field of textiles, can solve the problems of high stiffness, high specific resistance, high price, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0141] The fancy yarn prepared in this embodiment is a porous skeleton pattern yarn, wherein the core yarn is antibacterial polyester filament and Porel hollow fiber, and the fixed yarn is 80% of hollow polyester fiber, 10% of nettle fiber and 10% of seaweed fiber for blending processing The blended yarn; the decorative yarn is a blended yarn of 85% velvet fiber and 15% seashell fiber.

[0142] Preparation of fixed yarn:

[0143] (1) Raw material and wool oiling process: Spray 0.9% antistatic agent, appropriate amount of anti-slip agent and appropriate amount of water, and seal it for 12 hours before use;

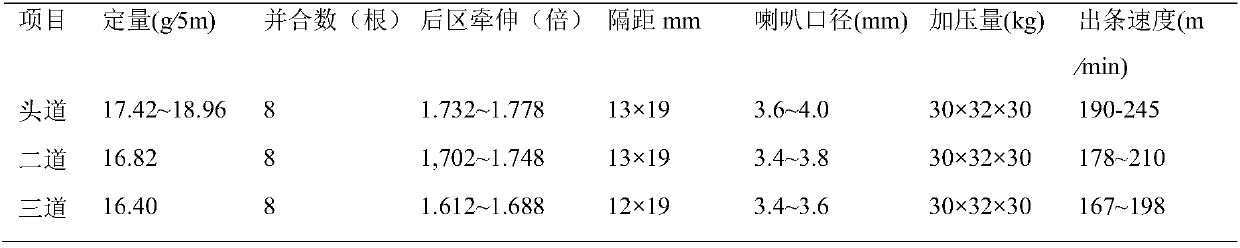

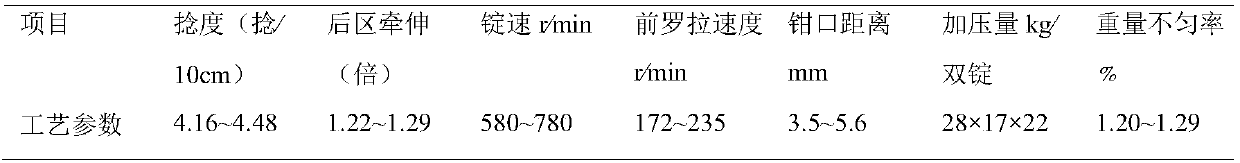

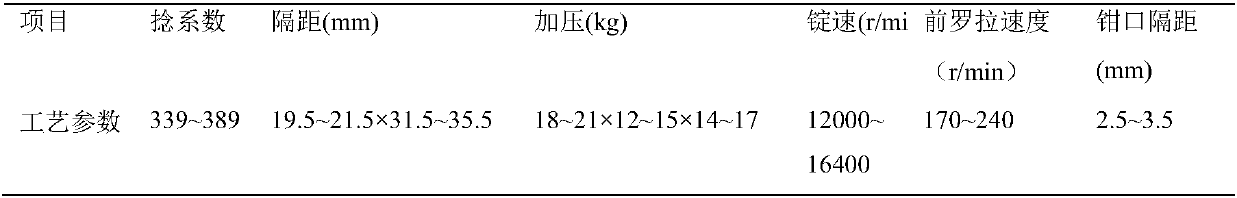

[0144] (2) Carding process: raw sliver weight 18.86g / 5m, feed roller ~ feed board import 0.28mm, outlet 0.13mm, licker-in board 0.17mm, licker-in speed 576r / min, cylinder speed 260r / min, cover plate speed is 90mm / min, licker-in cylinder gauge is 0.21mm, cylinder-cover plate gauge is adjusted to 0.39, 0.33, 0.31, 0.31, 0.33mm, cylinder-doffer gauge is 0.13mm, doffer-stripp...

Embodiment 2

[0153] The fancy yarn prepared in this embodiment is a porous skeleton pattern yarn, wherein the core yarn is antibacterial polyester filament and Porel hollow fiber, and the fixed yarn is 10% of hollow polyester fiber, 80% of nettle fiber and 10% of seaweed fiber for blending processing The blended yarn; the decorative yarn is a blended yarn of 15% velvet fiber and 85% seashell fiber.

[0154] Preparation of fixed yarn:

[0155] (1) Raw material and wool oiling process: Spray 1.2% antistatic agent, appropriate amount of anti-slip agent and appropriate amount of water, and seal it for 18 hours before use;

[0156] (2) Carding process: raw sliver weight 20.5g / 5m, feed roller ~ feed board import 0.30mm, exit 0.14mm, licker-in board 0.25mm, licker-in speed 650r / min, cylinder speed 310r / min, cover plate speed is 120mm / min, licker-in cylinder gauge is 0.23mm, cylinder-cover plate gauge is adjusted to 0.41, 0.35, 0.32, 0.32, 0.35mm, cylinder-doffer gauge is 0.15mm, doffer-strippin...

Embodiment 3

[0165] The fancy yarn prepared in this embodiment is a porous skeleton pattern yarn, wherein the core yarn is antibacterial polyester filament and Porel hollow fiber, and the fixed yarn is 10% of hollow polyester fiber, 10% of nettle fiber and 80% of seaweed fiber for blending processing The blended yarn; the decorative yarn is a blended yarn of 40% velvet fiber and 60% seashell fiber.

[0166] Preparation of fixed yarn:

[0167] (1) Raw material and wool oiling process: Spray 1.9% antistatic agent, appropriate amount of anti-slip agent and appropriate amount of water, and seal it for 12-24 hours before use;

[0168] (2) Carding process: raw sliver weight 22.86g / 5m, feed roller ~ feed board import 0.32mm, exit 0.15mm, licker-in board 0.31mm, licker-in speed 765r / min, cylinder speed 365r / min, cover plate speed is 184mm / min, licker-in cylinder gauge is 0.25mm, cylinder-cover plate gauge is adjusted to 0.45, 0.37, 0.33, 0.33, 0.37mm, cylinder-doffer gauge is 0.17mm, doffer-stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com