Trackless construction method for subway rigid catenary system

A technology of rigid contact and construction method, applied in the direction of overhead lines, etc., can solve the problems of long construction period, large operation interference, low work efficiency, etc., to improve construction efficiency, solve the delay of construction period, save time and manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

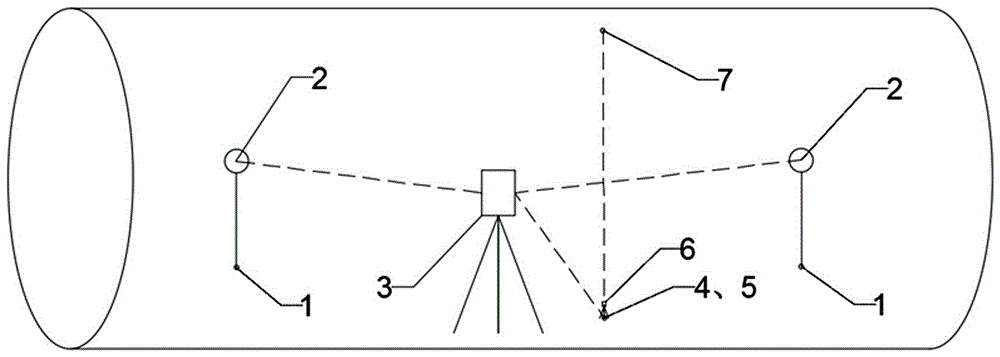

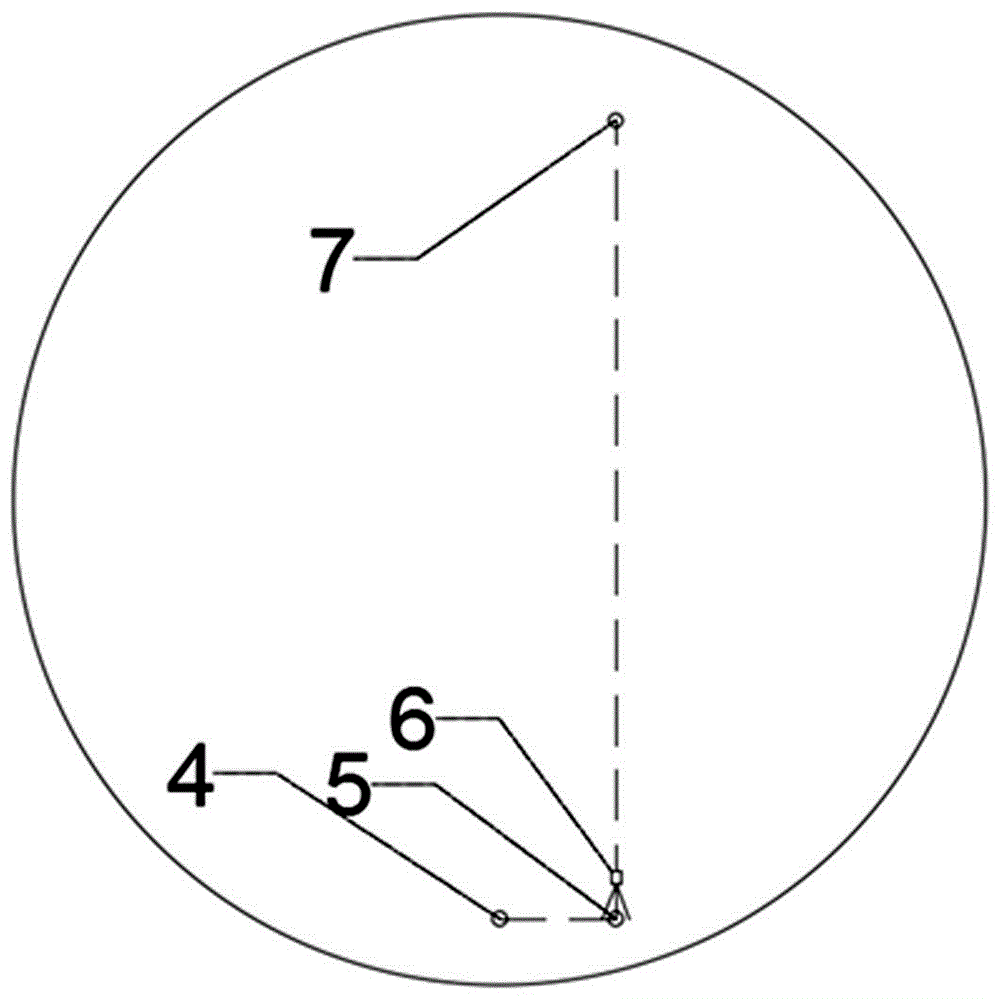

[0024] A kind of metro rigid catenary trackless construction method, such as figure 1 , 2 shown, including the following steps:

[0025] Step 1. Calculation of catenary suspension point 7

[0026] A. Determine the starting point. In the section with a turnout, select a position 4m away from the center of the turnout as the starting point, that is, the mileage of the starting point = the distance of the turnout - 4m; in the section without a turnout, select the anchor section joint The first point is the starting point, and the mileage of the starting point is the terminal mileage + span value obtained by direct measurement on the CAD drawing; B. Calculate the 7 mileage of each suspension point, and calculate the mileage of the next point through the span; that is The mileage of the next point = the mileage of the starting point + the span; if the anchor section is at the fork, use the Excel accumulation formula, that is, the mileage of the next suspension point 7 is equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com