A trackless construction method for flexible catenary in subway depot

A construction method and section flexible technology, which is applied in the field of flexible catenary trackless construction in subway depots, can solve problems such as easy conflicts in construction positions, tight construction schedules, and low construction efficiency, so as to improve prefabrication accuracy and construction efficiency, and solve The effect of delaying the construction period and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

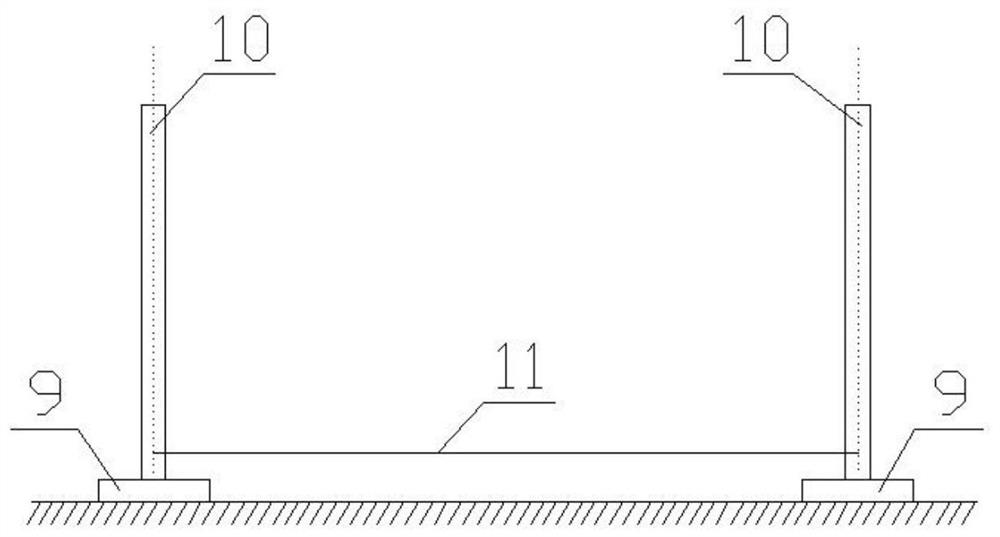

[0048] The following embodiments of the present invention in conjunction with the accompanying drawings are further elaborated:

[0049] An innovative trackless method of flexible catenary construction for metro depots consisting of the following steps:

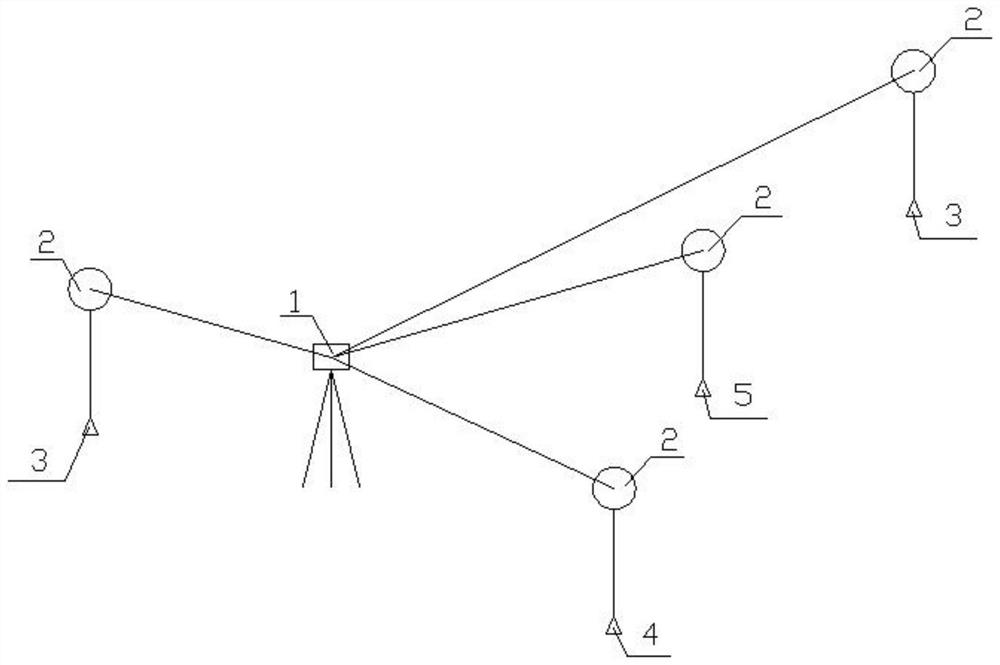

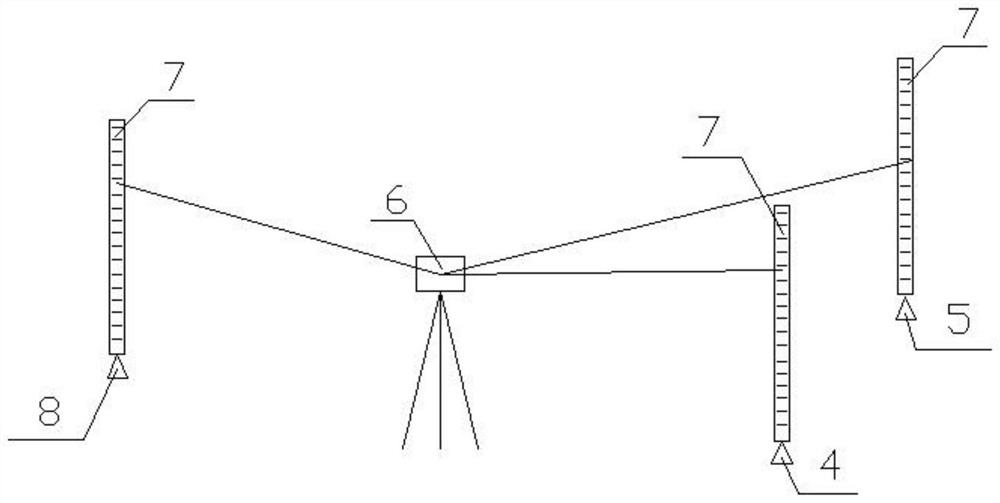

[0050] (1) Calculation of pillar piles, pull line foundation piles 5 and corresponding line center piles 4 point coordinates

[0051] a. Review the catenary layout of the vehicle segment to confirm that the pillars, the pull line foundation, the span, the pull-out value of the positioning point, and the limit are all arranged correctly;

[0052] b. Determine the starting test point, with the turnout center or building or bridge as the benchmark;

[0053] c. According to the catenary layout plan, the points of the pillars and pull line foundations are marked in the track pile coordinate chart;

[0054] d. Calculate the pillar, pull line foundation and the corresponding line center pile point coordinates in the track pile coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com